Pressurization process device for tobacco material online expansion

A technology for processing devices and materials, which is applied in the fields of tobacco, tobacco preparation, and tobacco processing, can solve the problems of affecting the puffing effect and color of tobacco materials, uneven moisture content of tobacco materials, and increased moisture content of tobacco materials, so as to reduce internal heat. Loss, maintain moisture and moisture uniformity, reduce the effect of material breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

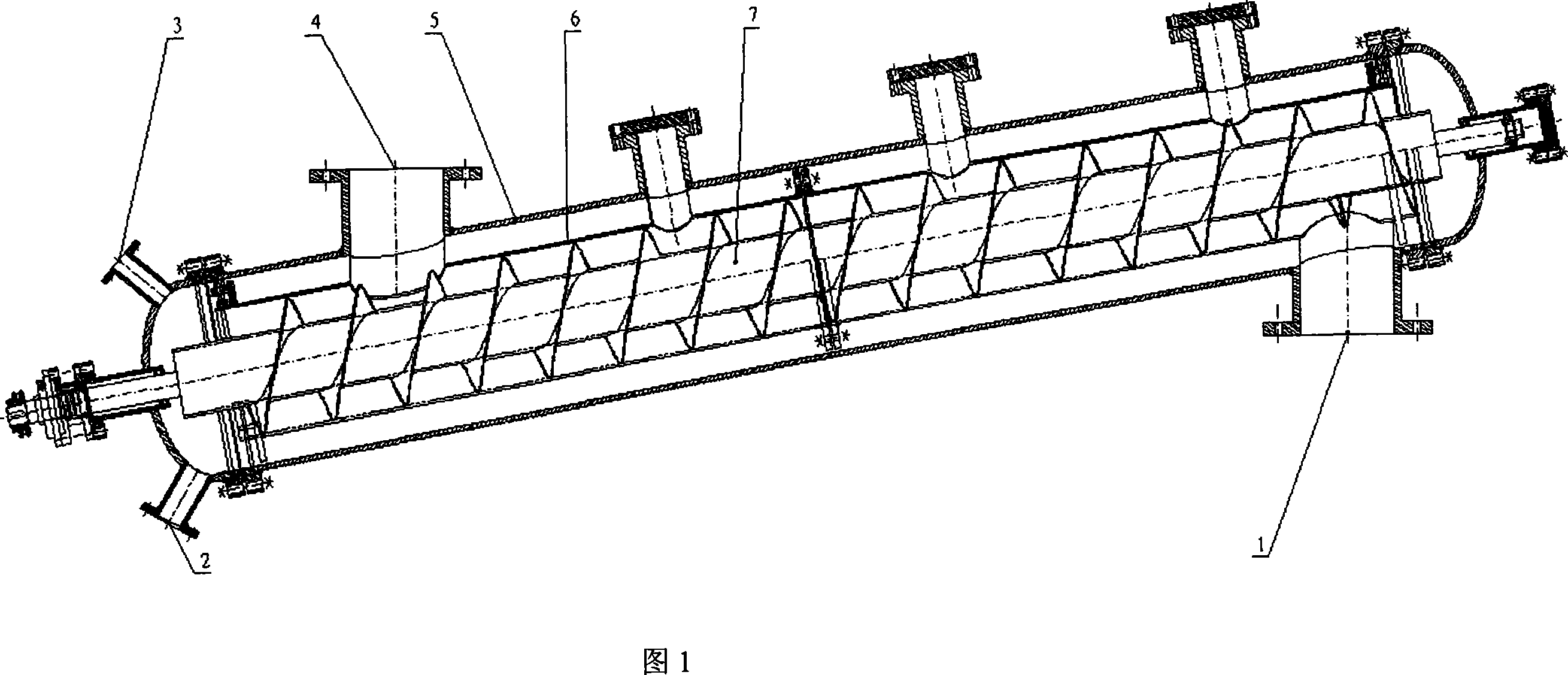

[0013] As shown in Figure 1, the pressurized treatment device of the present invention comprises a pressure-bearing outer shell 5 and a screw conveying body 7; an inner liner 6 is installed in the pressure-bearing outer shell 5 to separate the tobacco material and condensed water; the inner liner 6 is coaxially installed with the pressure-bearing shell 5 and the screw conveying body 7; the upper part of the end of the pressure-bearing outer shell 5 is provided with a steam input flange port 3, and the bottom of the same end is provided with a condensed water discharge port 2, and the condensed water The discharge port 2 is externally connected with a steam trap; the material input flange port 4 and the material output flange port 1 are respectively arranged at both ends of the pressure-bearing outer shell 5 and communicated with the inner bushing 6 respectively. The entire pressurized treatment unit is placed with the tail end tilted upwards.

[0014] During use, the condensed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com