Sensor for monitoring/measuring stress/ strain

A technology for measuring stress and sensors, which is applied in the field of sensors, can solve problems such as low survival rate, low sensitivity, and poor durability, and achieve the effects of high survival rate, high sensitivity, and good compatibility for embedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

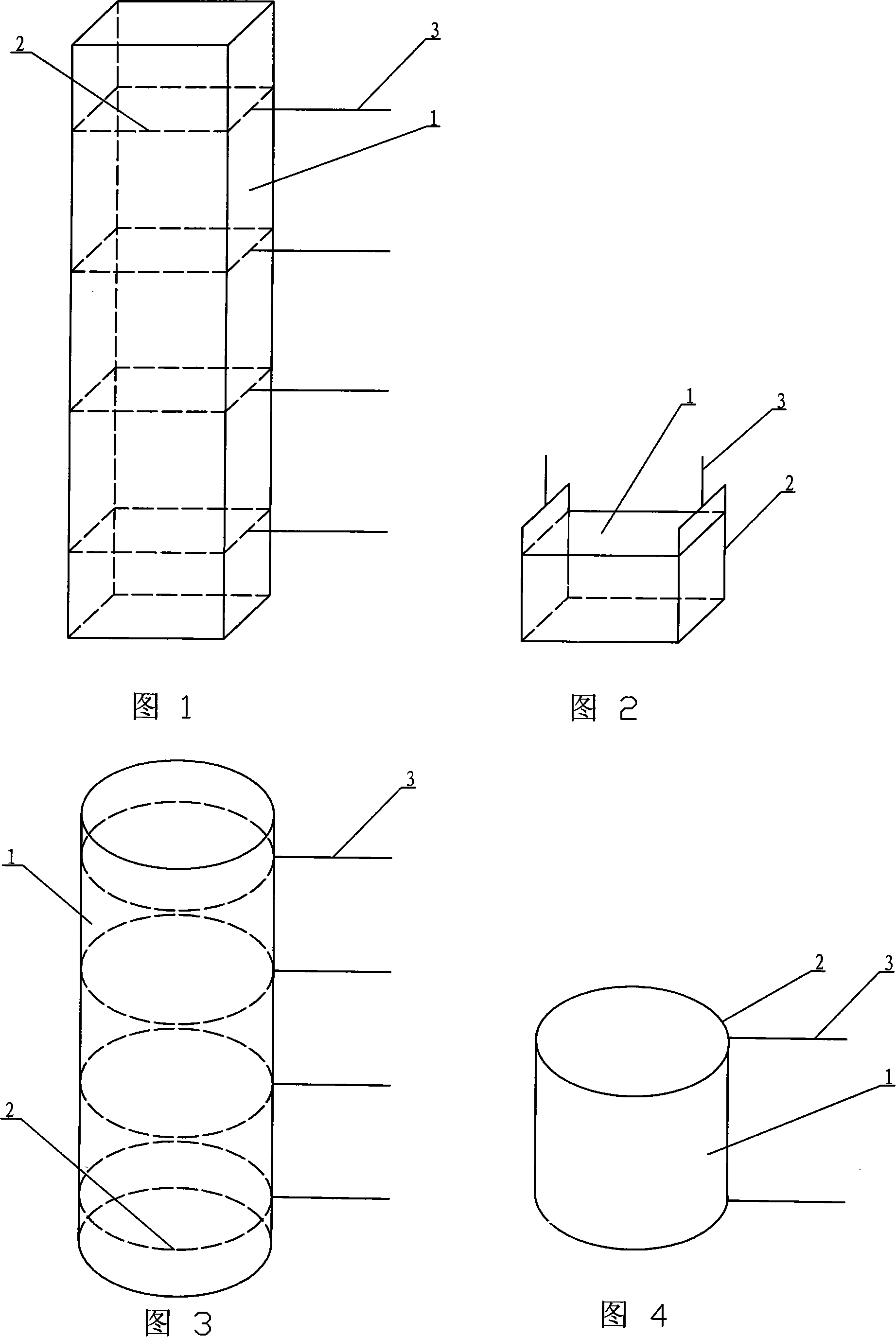

[0011] Specific implementation manner 1: This implementation manner is described in conjunction with FIG. 1 . This embodiment consists of a smart cement-based material 1 and a plurality of electrodes 2. The plurality of electrodes 2 are in the form of sheets, meshes or rings, buried in the smart cement-based material 1 at intervals or pasted or plated on the surface of the smart cement-based material.

[0012] The smart cement-based material is a mixture of conductive materials and cement-based materials, and its components are 1-80% by weight of conductive materials, and the balance is cement-based materials.

[0013] The conductive material is made of metal nickel powder alone, or by weight percentage of 10% to 70% of metal nickel powder and chopped carbon fiber, carbon fiber powder, steel slag, steel fiber, copper powder, graphite or carbon black or a variety of arbitrary proportions.

[0014] The electrodes are made of gold, silver, copper, stainless steel and materials w...

specific Embodiment approach 2

[0015] Specific Embodiment 2: In this embodiment, the plurality of electrodes 2 are in the shape of sheet, mesh or ring, and the plurality of electrodes 2 are configured as two electrodes, three electrodes or four electrodes by pasting, electroplating or embedding.

specific Embodiment approach 3

[0016] Specific Embodiment Three: This embodiment will be described in conjunction with FIG. 3 . In this embodiment, the smart cement-based material 1 is composed of nickel powder and cement stone. The nickel powder is 60.8% by weight, and the balance is prepared with ordinary cement-based materials. The casting method is adopted, and the four electrodes 2 are made of ring-shaped copper The electrode intervals are buried in the smart cement-based material 1, and the size of the sensor is 20mm×20mm×40mm. Its sensing relationship is shown in Table 1.

[0017] The test results show that the sensing element of the embodiment of the present invention has high sensitivity: the stress sensitivity is greater than 0.050 / MPa, and the strain sensitivity is higher than 895.5 (for example, the strain sensing sensitivity coefficient of the resistance strain gauge is only 2-3).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com