Explosion welding method for composite material of aluminum-steel

A composite material, explosive welding technology, applied in welding equipment, explosives, non-electric welding equipment, etc., can solve the problems of product scrap, non-composite, poor quality of explosive composite, etc., to achieve the effect of convenient production, improved efficiency and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

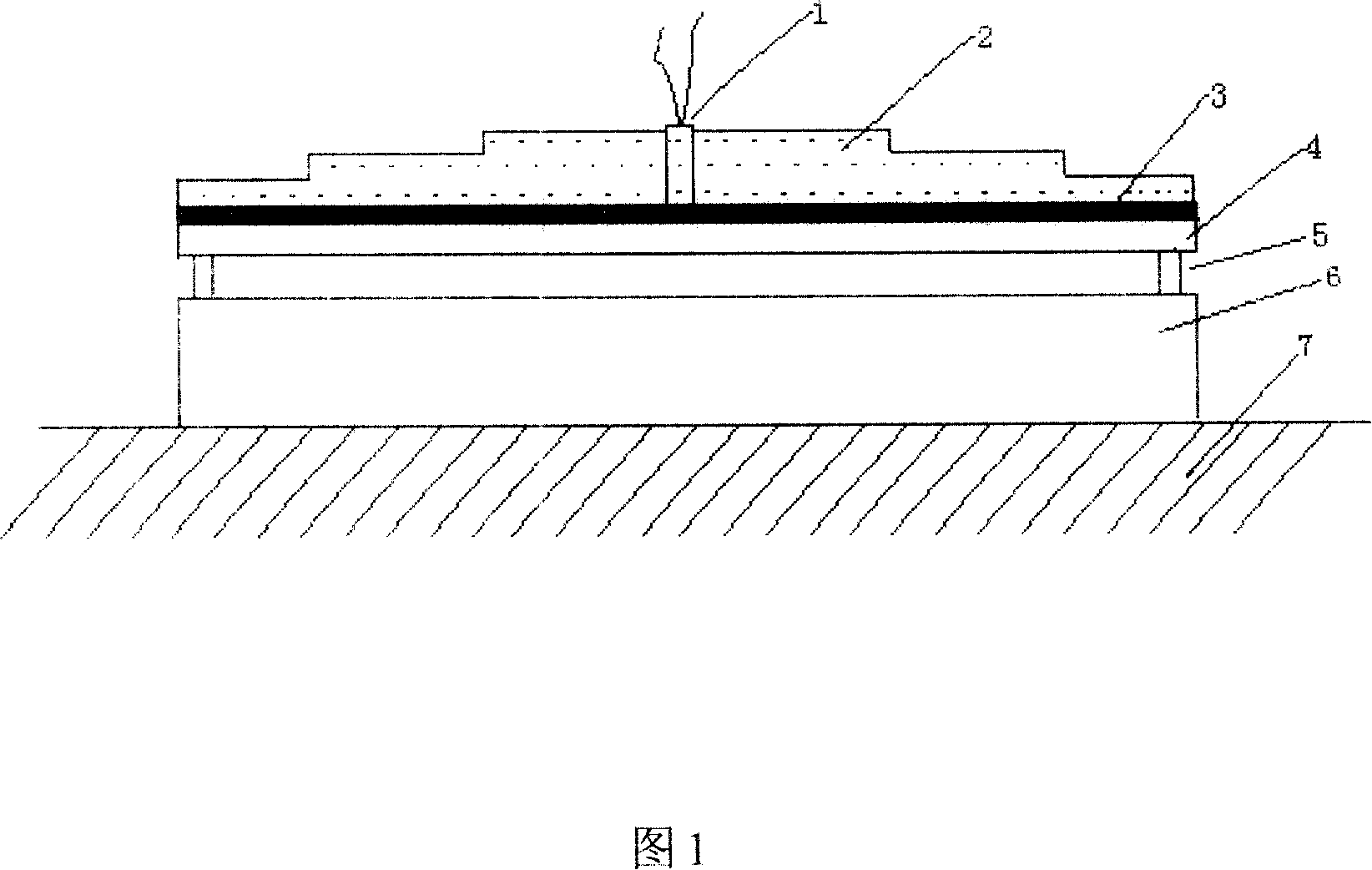

[0016] As shown in Figure 1: the base steel plate (6) and the clad aluminum plate (4) are polished with a grinding wheel or a polishing impeller to remove oxides on the metal surface to expose the metallic luster, and the base steel plate (6) is placed on the sand foundation (7 ), the clad aluminum plate (4) is placed on the base steel plate (6) through the support (5), the buffer protection layer (3) is pasted on the surface of the clad aluminum plate (4), and the explosive (2) is placed On the upper surface of the buffer protection layer (3), the explosive is an ammonium ladder explosive, which adopts a stepped gradient explosive distribution method, and the charge per unit area gradually decreases from the center of the plate surface to both ends, and is detonated by an industrial electric detonator (1). , aluminum-steel composites obtained by explosive welding.

[0017] Manufacture a piece of aluminum, aluminum alloy-steel composite material, the grade of the base steel pl...

specific Embodiment approach 3

[0018] As shown in Figure 1: the base steel plate (6) and the clad aluminum plate (4) are polished with a grinding wheel or a polishing impeller to remove oxides on the metal surface to expose the metallic luster, and the base steel plate (6) is placed on the sand foundation (7 ), the clad aluminum plate (4) is placed on the base steel plate (6) through the support (5), the buffer protection layer (3) is pasted on the surface of the clad aluminum plate (4), and the explosive (2) is placed On the upper surface of the buffer protection layer (3), the explosive is an ammonium ladder explosive, which adopts a stepped gradient explosive distribution method, and the charge per unit area gradually decreases from the center of the plate surface to both ends, and is detonated by an industrial electric detonator (1). , aluminum-steel composites obtained by explosive welding.

[0019] Manufacture a piece of aluminum, aluminum alloy-steel metal composite material, the grade of the base st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com