Waste gas pre-heating type glory hole

A heating furnace and preheating technology, applied in the direction of heat treatment furnaces, furnaces, furnace types, etc., can solve the problems of environmental pollution, good economic benefits, waste of heat energy, etc., and achieve the effects of uniform temperature, good economic benefits, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

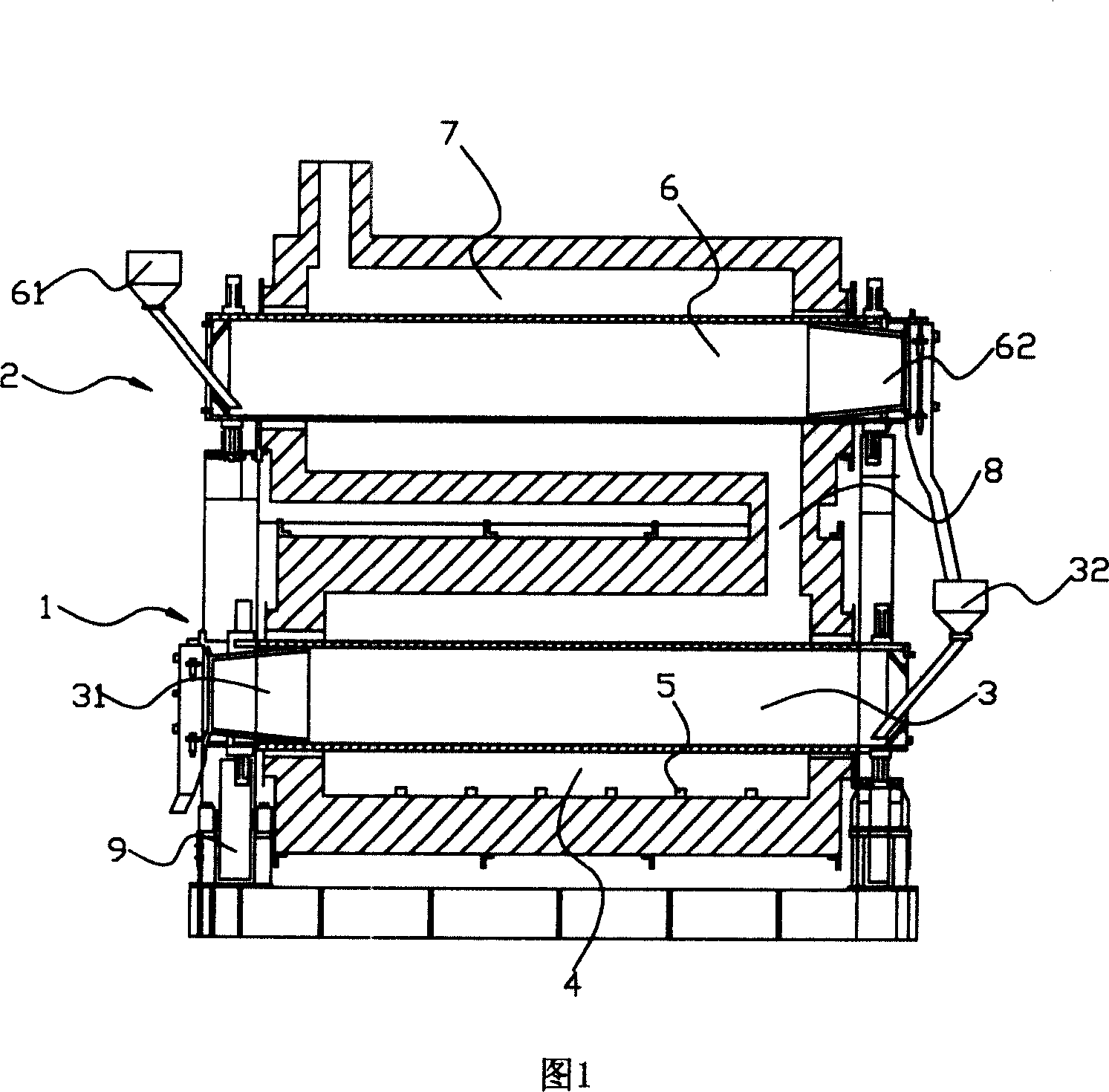

[0018] An exhaust gas preheating furnace, as shown in FIG. 1 , comprises a lower heating furnace 1 and an upper preheating furnace 2 arranged on the lower heating furnace 1 . The lower heating furnace 1 is made of refractory bricks, and is equipped with a first furnace 3 and a lower heating cavity 4. There are several heating nozzles 5 in the lower heating cavity, and the first furnace 3 passes through the lower heating cavity 4. , heating the first furnace 3 through the heating nozzle 5; the upper preheating furnace 2 is made of refractory bricks, and is equipped with a second furnace 6 and an upper heating cavity 7, and the second furnace 6 passes through the upper heating cavity body 7; and between the upper heating cavity 7 and the lower heating cavity 4, a connecting channel 8 is provided, through which the high-temperature flue gas generated in the lower heating cavity 4 is sent to the upper heating cavity 7 for The second furnace 6 is heated. In this embodiment, the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com