Laser source device, image display device and monitor device having the same

A technology of laser light source and light source, which is applied to lasers, laser parts, phonon exciters, etc., can solve the problems of fundamental wave laser light source power reduction, little improvement in light utilization efficiency, and no improvement in light utilization efficiency, etc. High degree of freedom, easy control, and consistent polarization direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

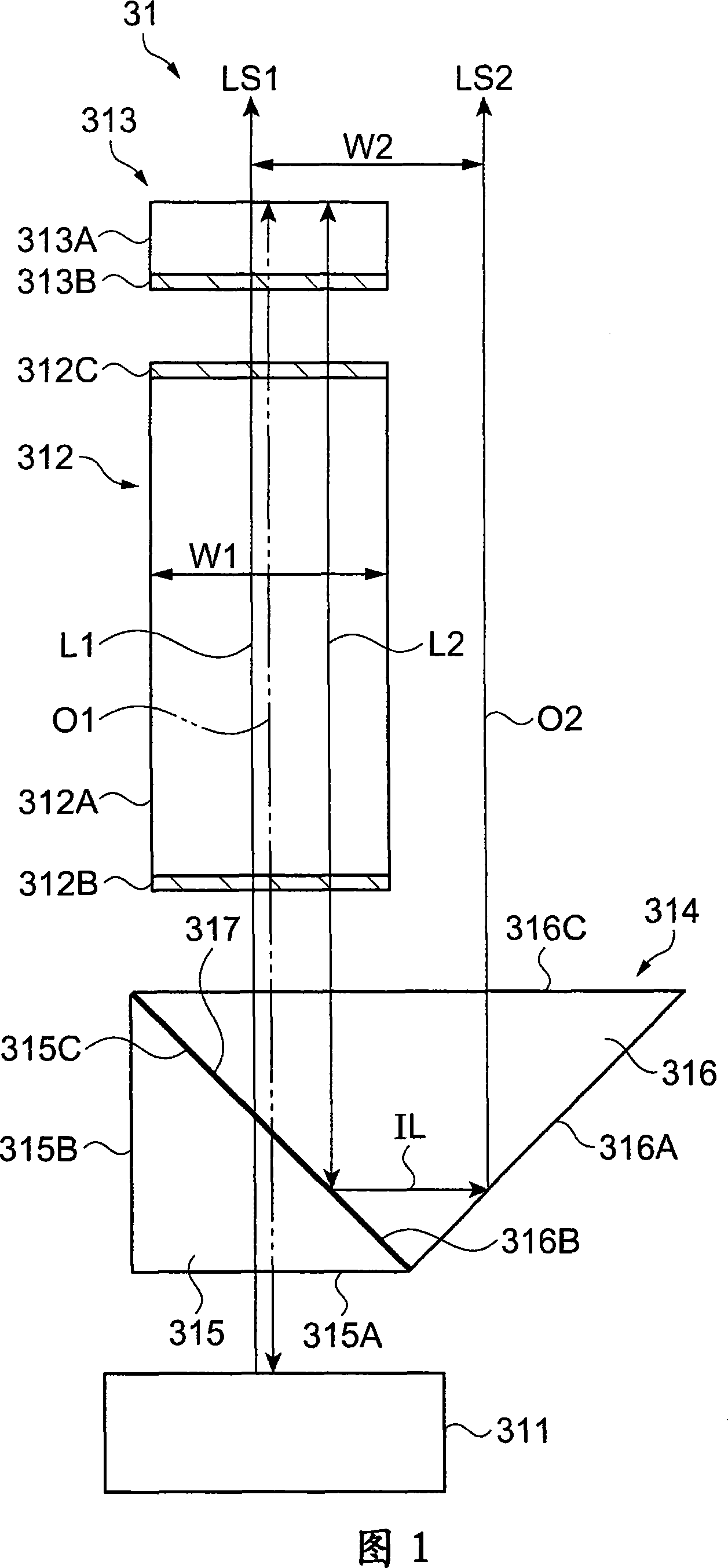

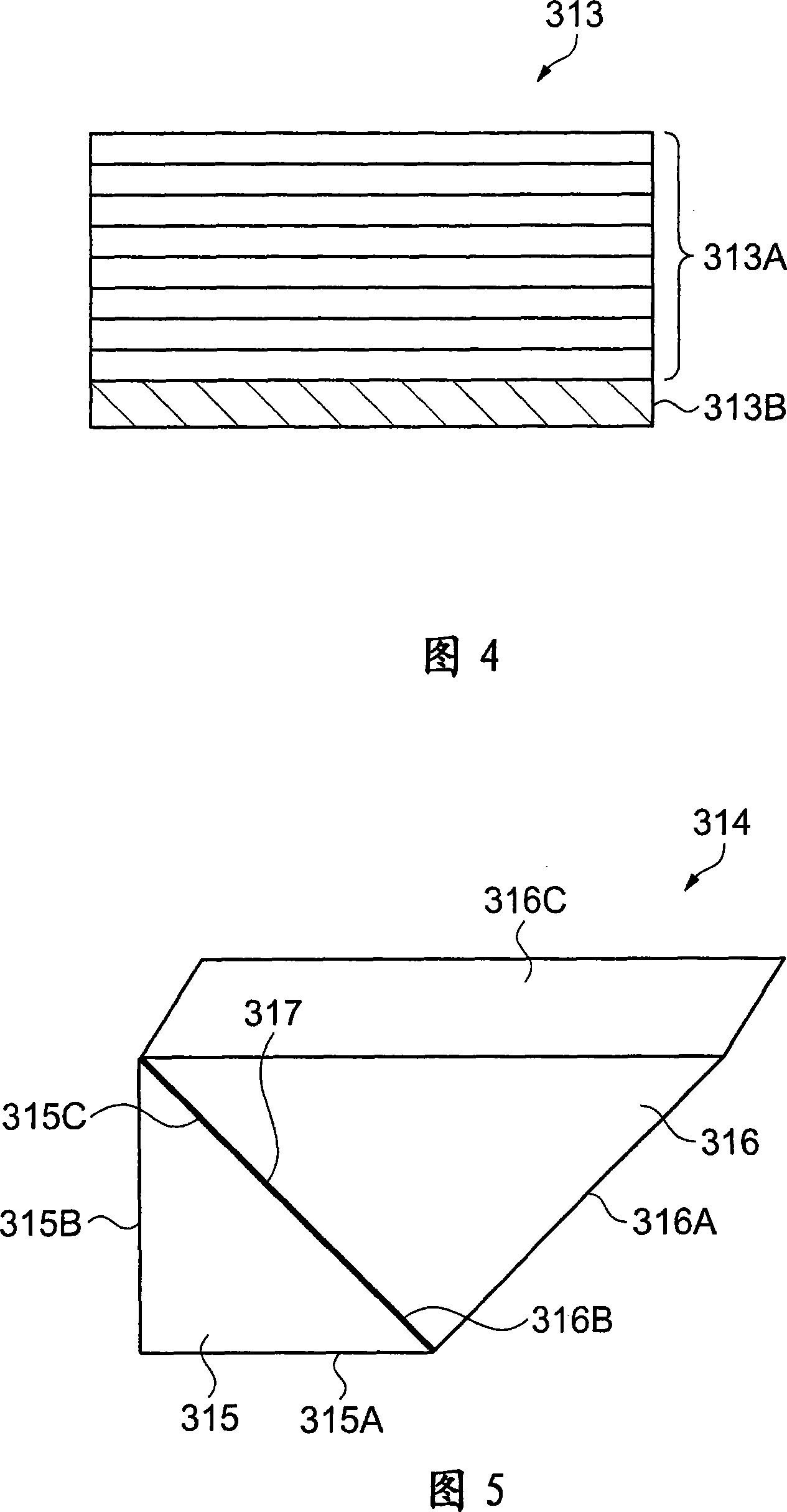

[0048] FIG. 1 is a schematic diagram showing a schematic configuration of a laser light source device in a first embodiment. The laser light source device 31 includes a light source 311 , a wavelength conversion element 312 , an external resonator 313 , and an optical path conversion element 314 . The light source 311 emits light of the first wavelength.

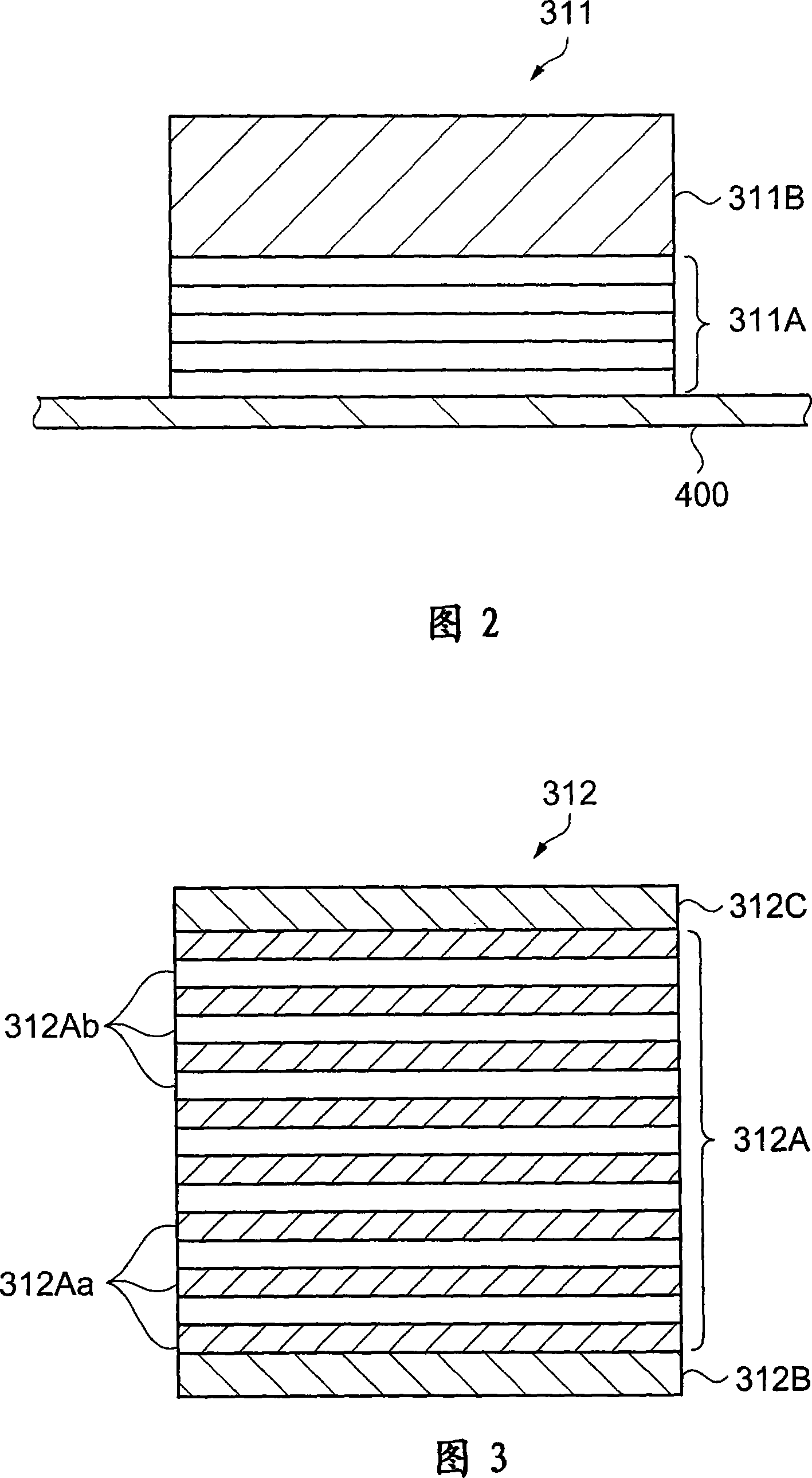

[0049] FIG. 2 is a cross-sectional view schematically showing the structure of the light source 311 . The light source 311 shown in FIG. 2 is a so-called surface-emitting semiconductor laser, and has: a substrate 400 made of, for example, a semiconductor wafer, a mirror layer 311A formed on the substrate 400 and having a function as a reflection mirror, and laminated on the substrate 400. The laser medium 311B on the surface of the mirror layer 311A.

[0050] The mirror layer 311A is formed on the substrate 400 by, for example, a laminate of a high-refractive-index dielectric and a low-refractive-index dielectric forme...

no. 2 approach

[0098] FIG. 6 is a schematic diagram showing a schematic configuration of a laser light source device 41 in the second embodiment. The laser light source device 41 of the second embodiment differs from the laser light source device 31 of the first embodiment only in the configuration of the optical path conversion element 414, and is the same as that of the first embodiment other than that. Therefore, in FIG. 6 , the same members as those in the first embodiment are given the same reference numerals, and descriptions thereof are omitted or simplified. Furthermore, the same applies to the process up to obtaining output light from the laser light source device 41 , and its detailed description is also omitted or simplified.

[0099] In the laser light source device 41 shown in FIG. 6 , the optical path conversion element 414 includes a plate-shaped member 414A as a translucent member, a selective reflection film 317 , and a reflection film 416 . The plate member 414A is made of...

no. 3 approach

[0113] FIG. 7 is a schematic diagram showing a schematic configuration of a laser light source device in a third embodiment. The laser light source device 51 of the third embodiment differs from the laser light source device 31 of the first embodiment only in the configuration of the optical path conversion element 514, and is the same as the first embodiment described above except for that. Therefore, the same reference numerals are assigned to the same components as those in the first embodiment, and descriptions thereof will be omitted or simplified. Furthermore, the same applies to the process up to obtaining output light from the laser light source device 51 , and its detailed description is also omitted or simplified.

[0114] In the laser light source device 51 shown in FIG. 7 , an optical path conversion element 514 includes a prism 515 as a translucent member, and a selective reflection film 317 . The prism 515 is made of optical glass such as BK7 and has the shape o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com