Automatic flushing apparatus of membrane filter in water purifier

An automatic flushing and filter technology, which is applied in the direction of filtration separation, filtration treatment, membrane, etc., can solve the problems of shortening the service life of membrane filters, not having enough times to remove scale, troubles in scale removal process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

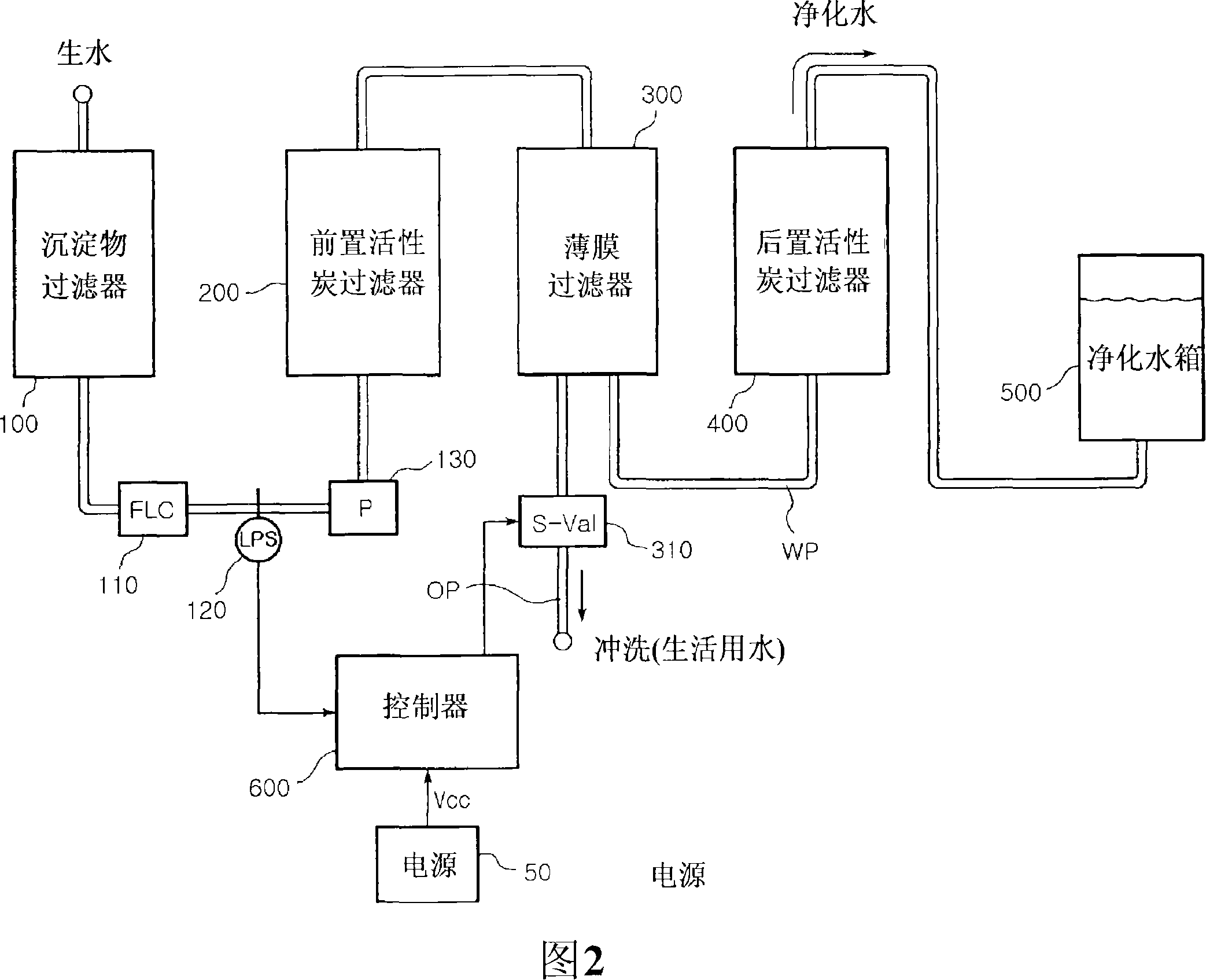

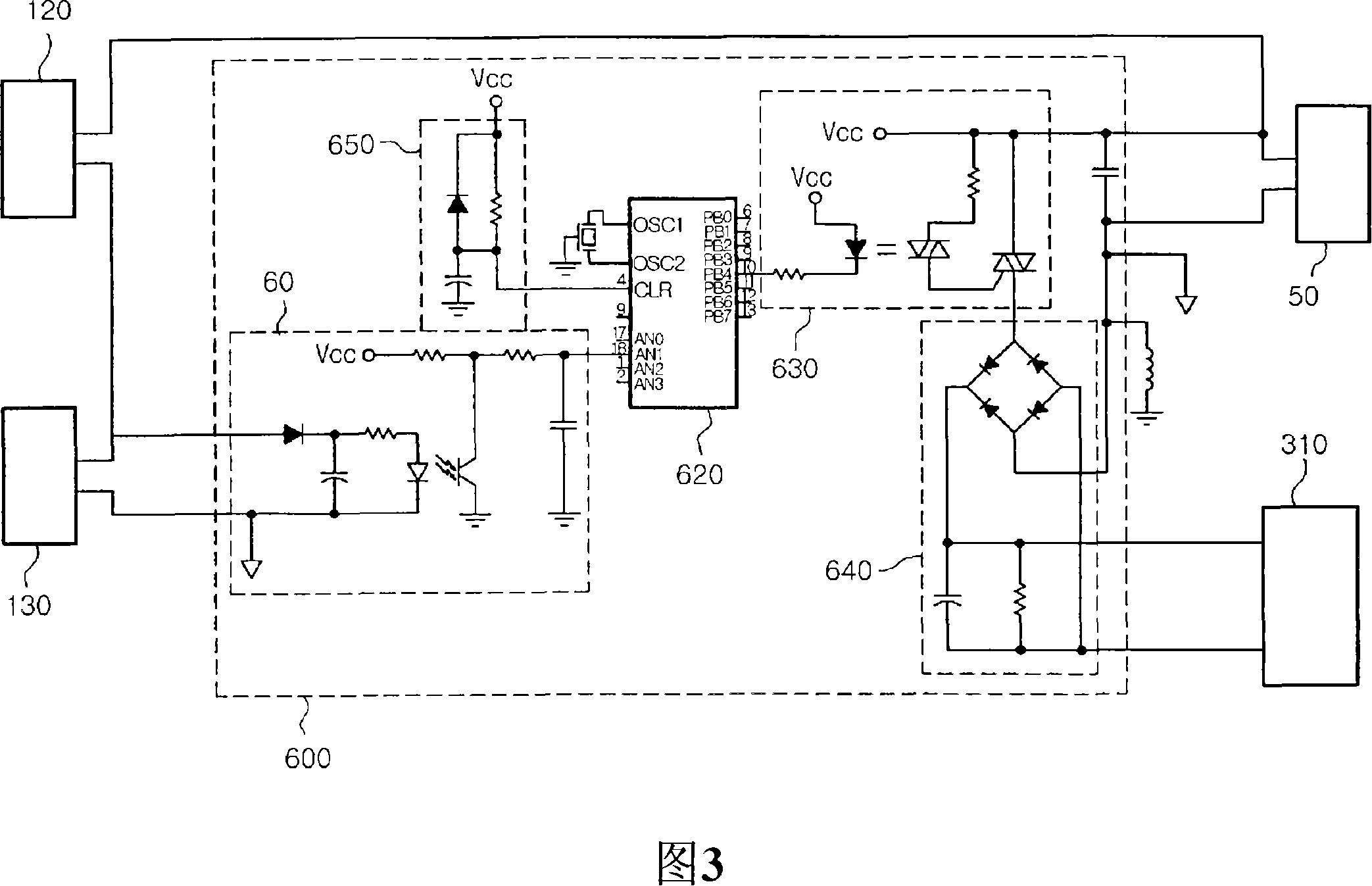

[0023] The present invention will now be described more fully hereinafter with reference to the accompanying drawings, wherein like reference numerals refer to like parts throughout.

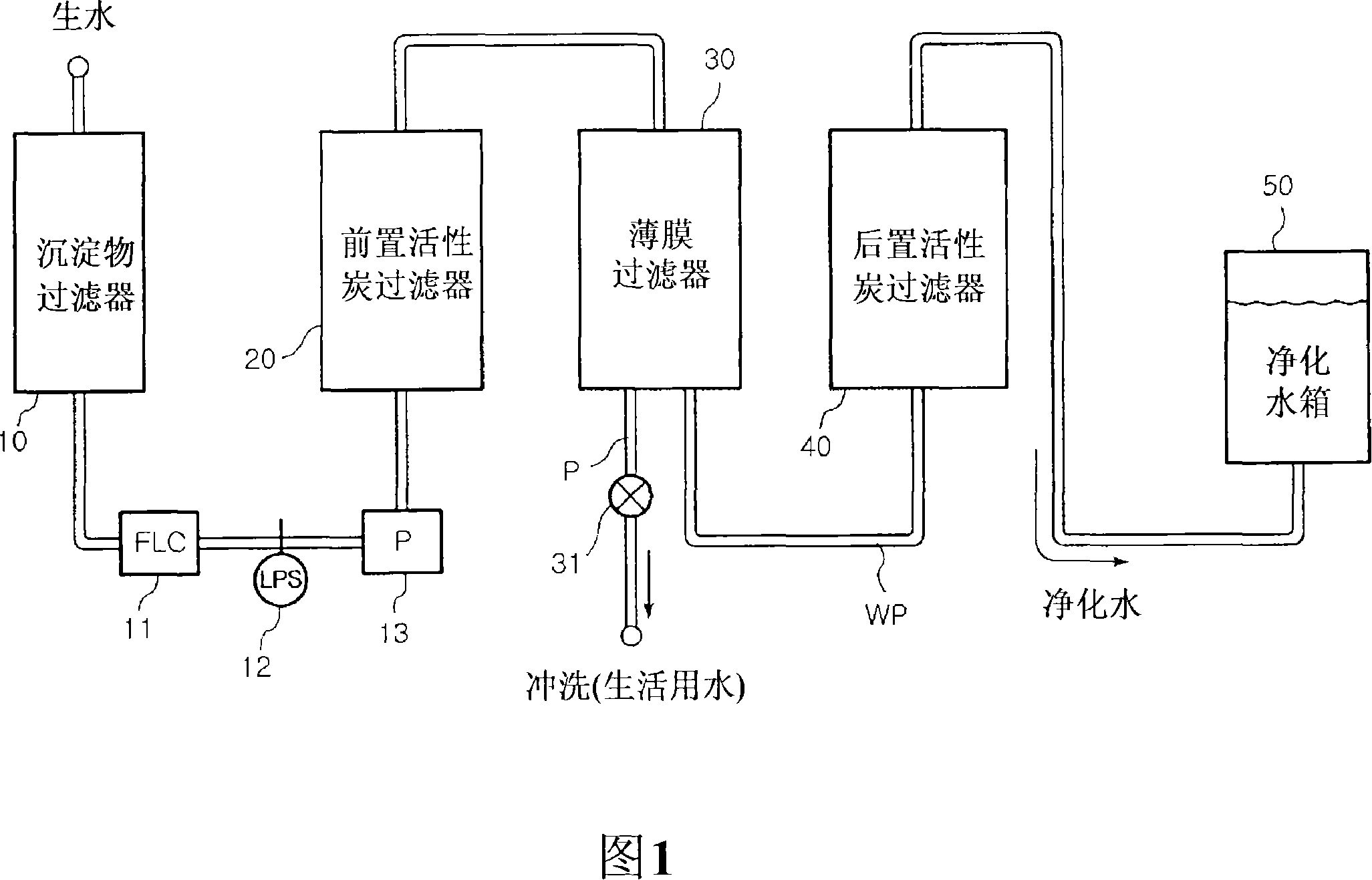

[0024] Fig. 2 is a structural view of an automatic flushing device for a membrane filter in a water purifier according to the present invention. Referring to FIG. 2, the water purifier includes a sediment filter 100 for removing fine foreign matter from raw water, and a pre-activated carbon filter 200 for removing harmful chemical substances from water supplied by the sediment filter 100. , a membrane filter 300 for removing heavy metals from the water supplied by the pre-activated carbon filter 200, and a post-activated carbon filter 400 for removing unpleasant taste or odor and pigments from the water supplied by the membrane filter 300 , and a water tank 500 for containing purified water supplied from the post activated carbon filter 400 .

[0025] The water purifier also includes FLC110 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com