Preparation method of cast-in-place concrete filling thin wall carcass

A production method and concrete technology, which is applied in the field of building materials, can solve the problems of increasing manufacturing costs, large formwork materials, and great differences in physical and chemical properties, and achieve the effects of reducing costs, saving materials, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

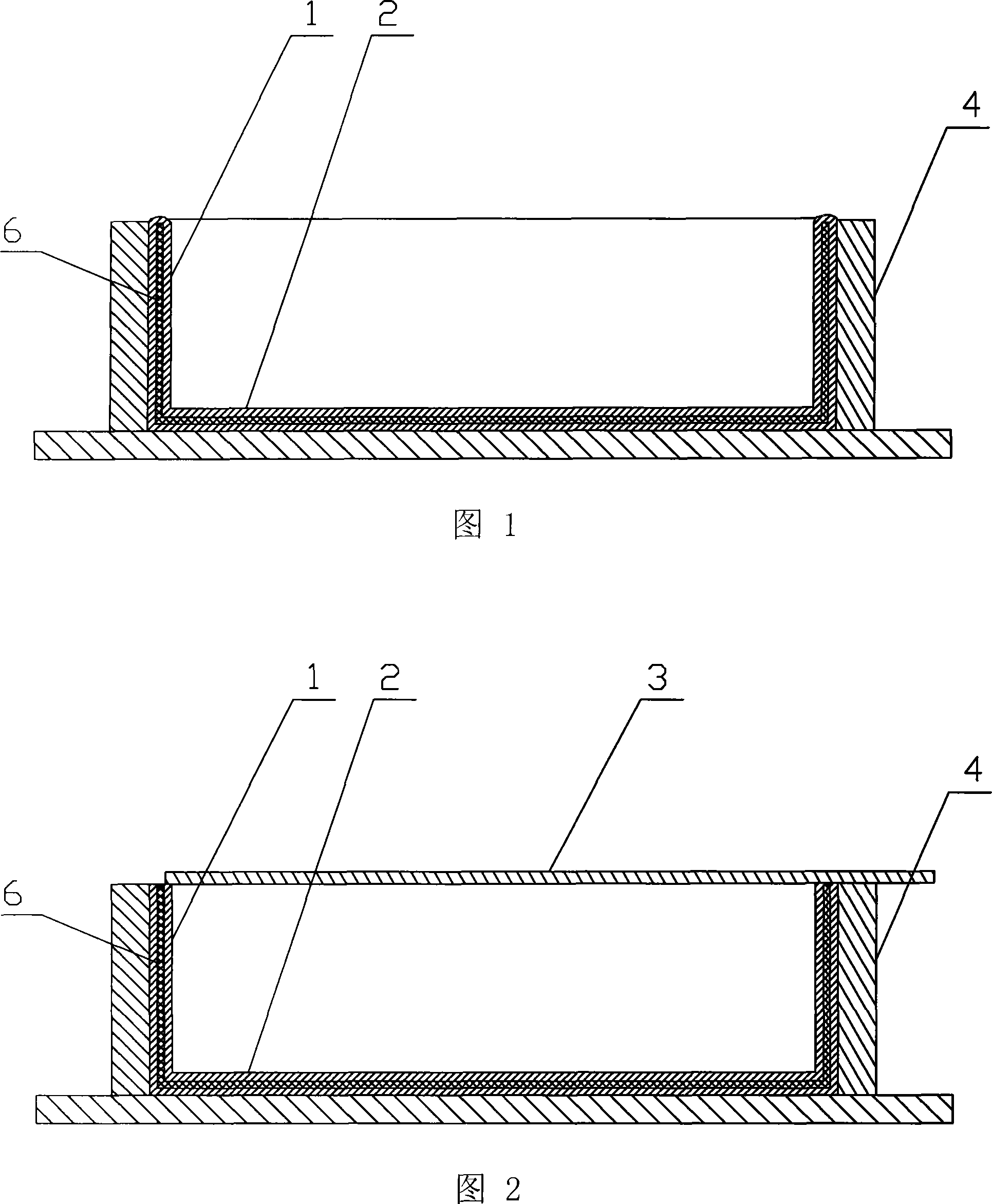

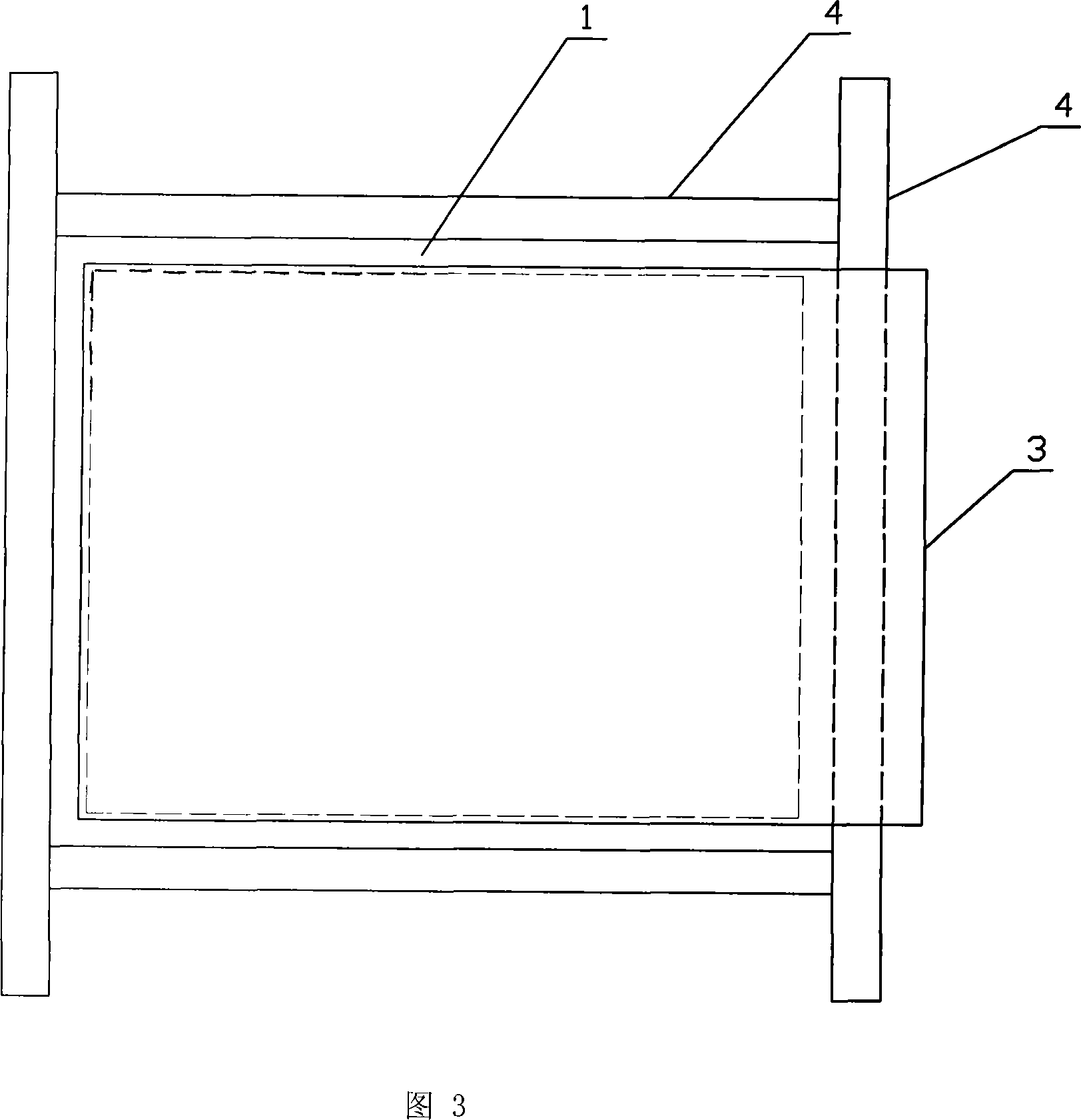

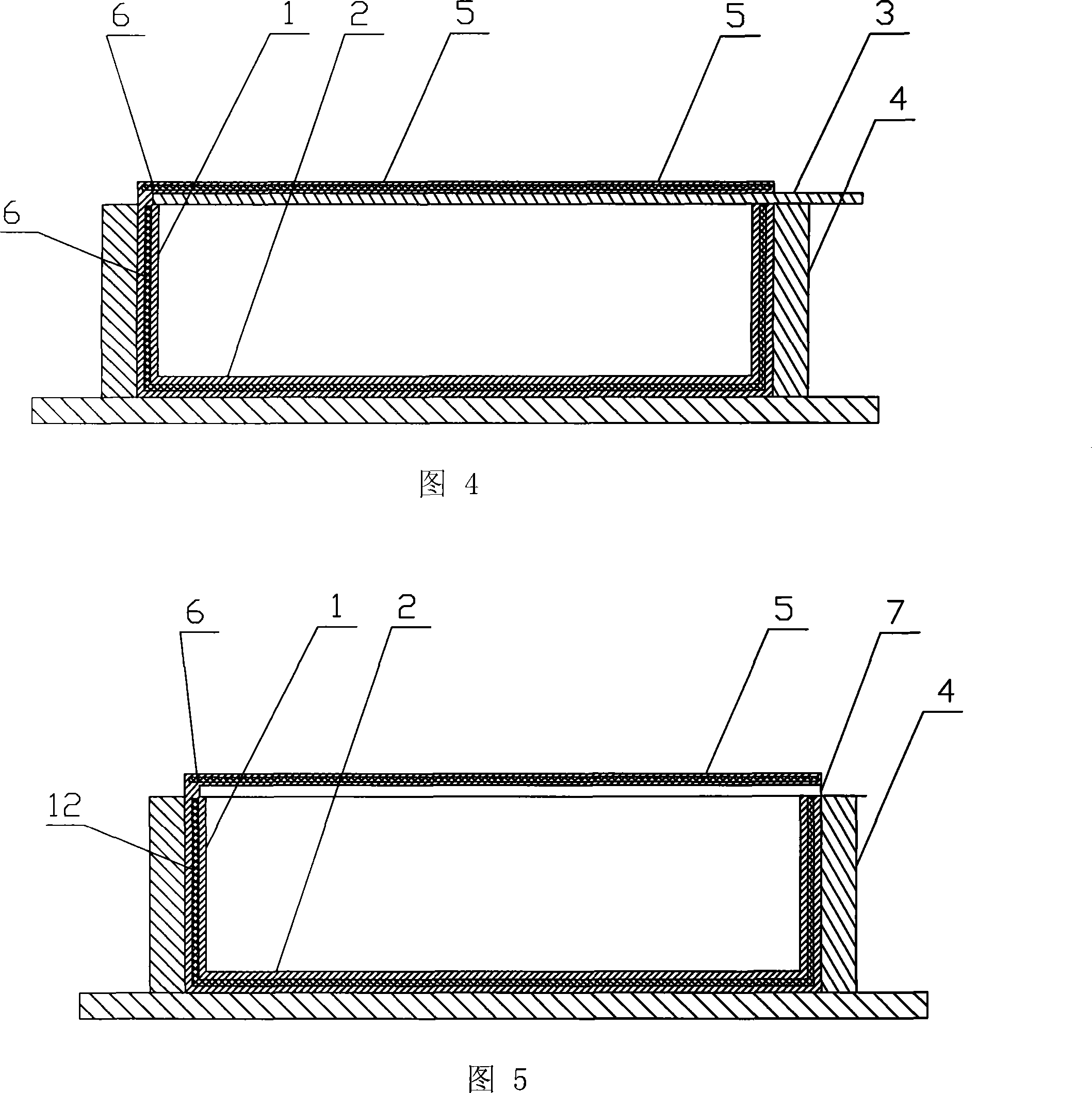

[0020] The manufacturing method of the thin-walled carcass for filling cast-in-place concrete in Example 1 of the present invention is as follows: the carcass material used is cement mortar, as shown in Figure 1, first in the outer mold 4 with wet loose cement mortar to smear the surrounding sides of one body Wall 1 and base plate 2, glass fiber mesh 6 is also added in the surrounding side walls 1 and base plate 2 as a reinforcement layer, as shown in Figure 2 and Figure 3, a quadrilateral inner mold supporting plate 3 is placed on the top of the surrounding side walls 1, and the inner mold One edge of the supporting plate 3 protrudes outside the outer membrane 4, and the remaining three edges of the inner mold supporting plate 3 are placed on the tops of the three sides of the mortar body of the surrounding side walls 1 respectively. The edge that is combined with cement mortar is sprayed with release agent to facilitate demoulding; Then as shown in Figure 4, cement mortar is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com