Exterior outer-insulating system construction method for using direct-compress EPS inorganic clad plate

A technology for external wall insulation and construction methods, applied in the direction of insulation, building components, sustainable waste treatment, etc., can solve the problems of high cost, large wet work, and low construction efficiency, and achieve low cost, convenient cutting, and smooth construction process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

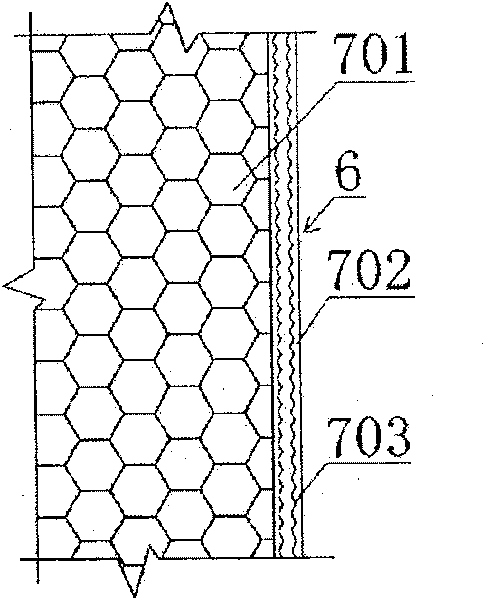

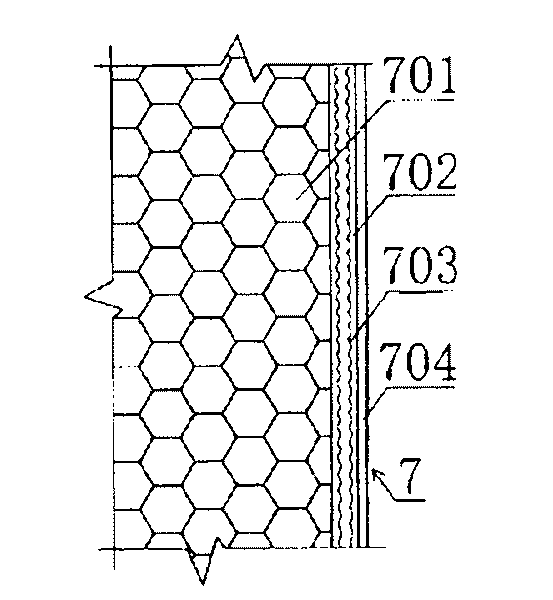

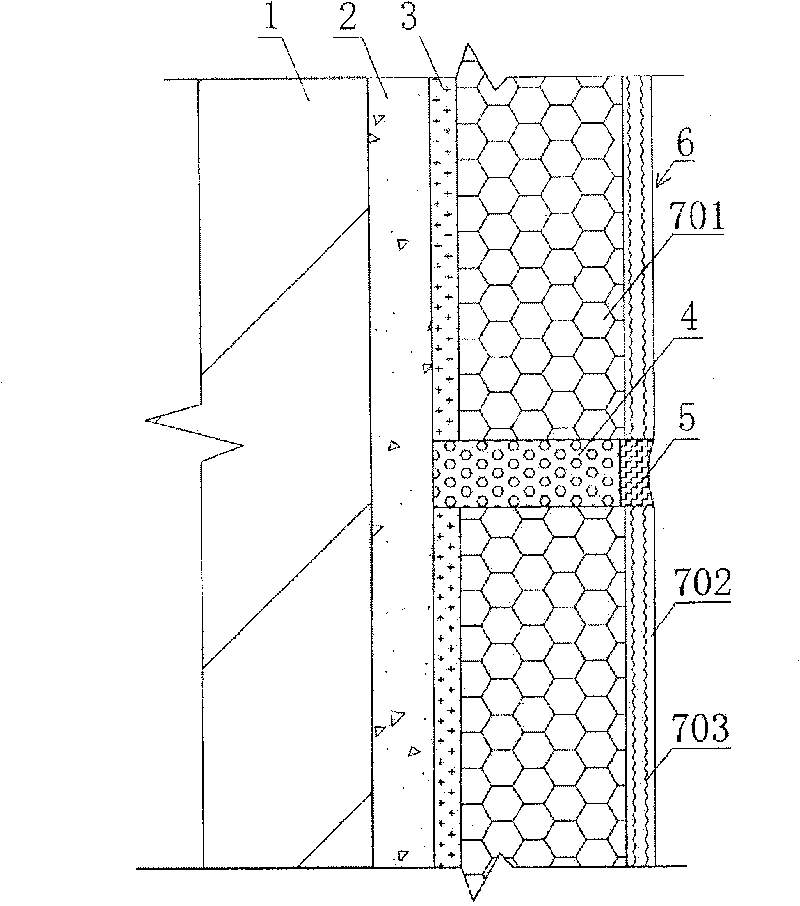

[0090] For examples of direct-coated EPS inorganic composite boards, see figure 1 As shown, it includes an expanded EPS board 701 and an inorganic composite material reinforcement layer 702. The inorganic composite material reinforcement layer is directly laid on one side of the expanded EPS board by mechanical means and passed through a pressure roller to form an integrated direct-applied EPS inorganic material. Composite board6. The panel is a single panel, and an inorganic composite material reinforcement layer 702 containing two layers of grid cloth 703 is compounded on the surface of one side of the expanded EPS board 701, and the two layers of grid cloth are evenly distributed parallel to the board surface in the inorganic cementitious material , which is equivalent to making a protective layer of "three glues and two nets" on the expanded EPS board at one time. The size of the board is 600×1200 or 600×800. The mesh cloth 703 can be a glass fiber alkali-resistant mesh ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com