Beam column connecting structure of modular steel structure building

A beam-to-column connection and steel structure technology, applied in building construction, construction, etc., can solve problems such as difficult central column joints, affecting the flexibility of modular steel structure layout, lack of construction space, etc. Flexibility in layout and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

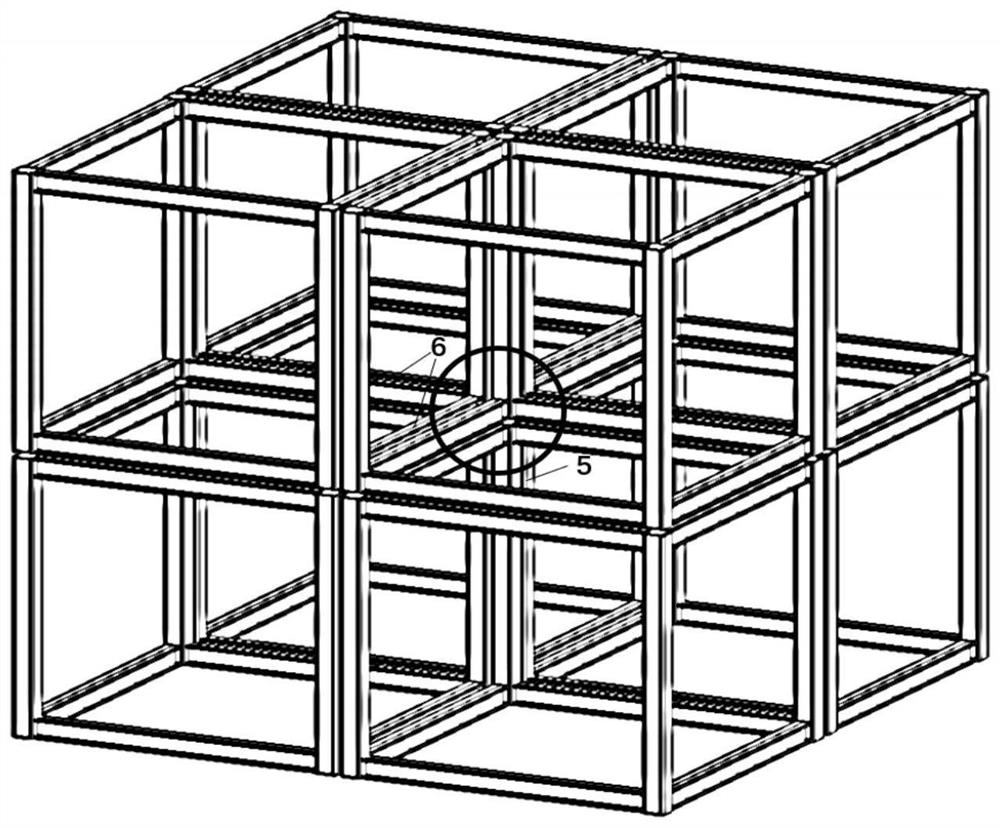

[0046] In this embodiment, the connection of 8 columns and 16 beams is used as an example for description. figure 1 As shown in the figure, the modular unit building consists of 8 closely arranged modular units. The 8 modular units are provided with two groups of front and rear, each group is provided with 4 modules, and the two-by-one row is distributed on the upper and lower floors. The central column node includes 8 frames. Column 5 and 16 frame beams 6.

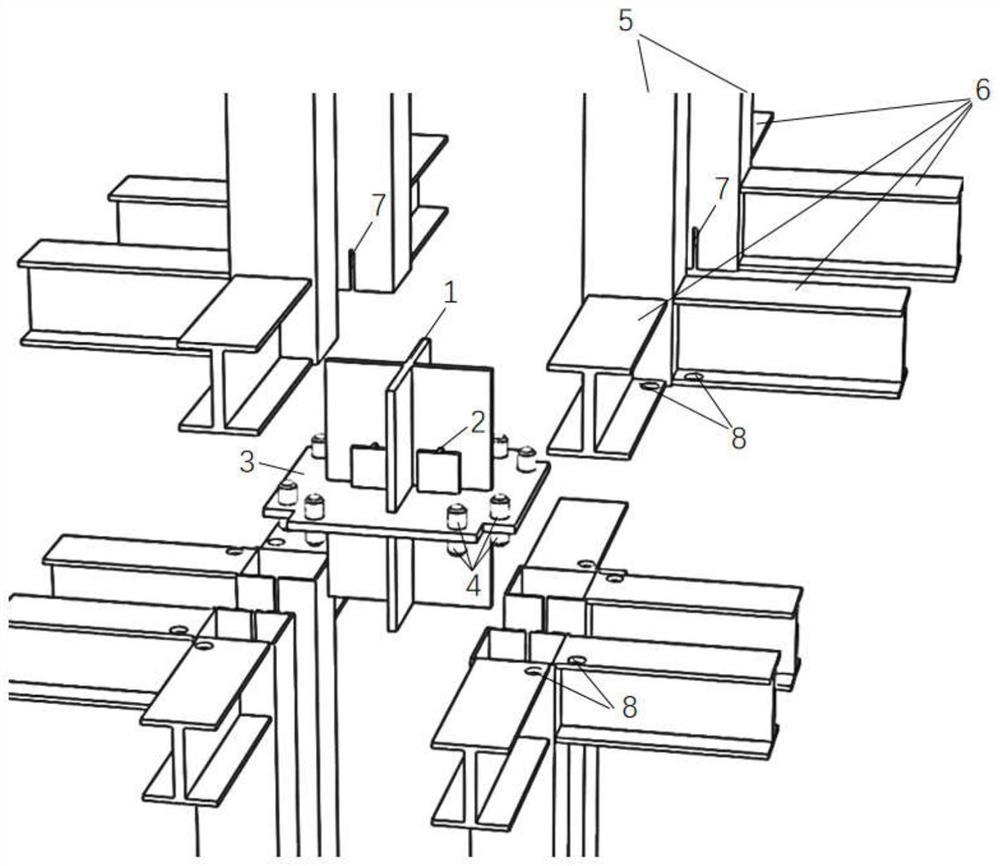

[0047] Based on the above connection of 8 columns and 16 beams, a beam-column connection structure of a modular steel structure building of the present invention is composed of beam-column node connectors and beam-column module units. The specific implementation method is as follows:

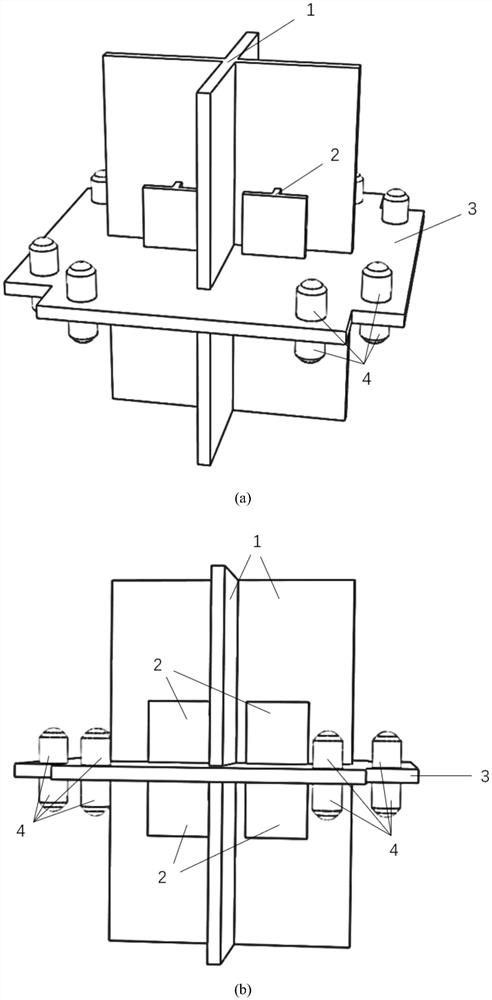

[0048] image 3Shown is the structural schematic diagram of the beam-column joint connector of the present invention. A square steel plate is selected, and a square notch is cut off at its four corners to make a bearing plate 3; two ident...

Embodiment 2

[0052] Embodiment 2 is another use case of the present invention, such as Figure 7 As shown, the connection situation 1 of the beam-column module unit of 4 columns and 8 beams, that is, there are 4 beam-column module units arranged closely, and the 4 beam-column module units are provided with two groups of front and rear, and each group is provided with 2 beam-column modules The unit is distributed in a single-story "field" shape, and the nodes include 4 frame columns 5 and 8 frame beams 6. That is, the connection structure of the 4-column and 8-beam in this embodiment is a 1 / 2 connection structure of the beam-column modular unit of the 8-column and 16-beam.

[0053] The principle of this embodiment is similar to that of Example 1, but the difference between this embodiment and Embodiment 1 is that the beam-column joint connecting piece consists of a cross-shaped positioning steel plate 1, four limit steel plates 2, and a bearing plate 3, Eight cylindrical steel members 4 ar...

Embodiment 3

[0058] Embodiment 3 is another use case of the present invention, such as Figure 10 As shown, the connection situation 2 of the beam-column module unit of 4 columns and 8 beams, that is, there are 4 beam-column module units arranged closely, and the 4 beam-column module units are provided with two groups of front and rear, and each group is provided with 2 beam-column modules Each 2 beam-column module units are distributed on the upper and lower floors, and the nodes include 4 frame columns 5 and 8 frame beams 6 . That is, the connection structure of the 4-column and 8-beam in this embodiment is a 1 / 2 connection structure of the beam-column modular unit of the 8-column and 16-beam.

[0059] The principle of this embodiment is similar to that of Example 1, but the difference between this embodiment and Embodiment 1 is that the beam-column joint connecting piece consists of two T-shaped positioning steel plates 1, four T-shaped limiting steel plates 2, and one bearing plate 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com