Vacuum freezing drying cabin

A technology of vacuum freeze-drying and drying chamber, which is applied in the directions of drying solid materials, heating to dry solid materials, and non-heating to dry solid materials, etc., which can solve the problems of increasing production costs, difficulty in expansion and upgrading, etc., to improve production capacity , improve work efficiency, and have strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiment of the present invention is described below:

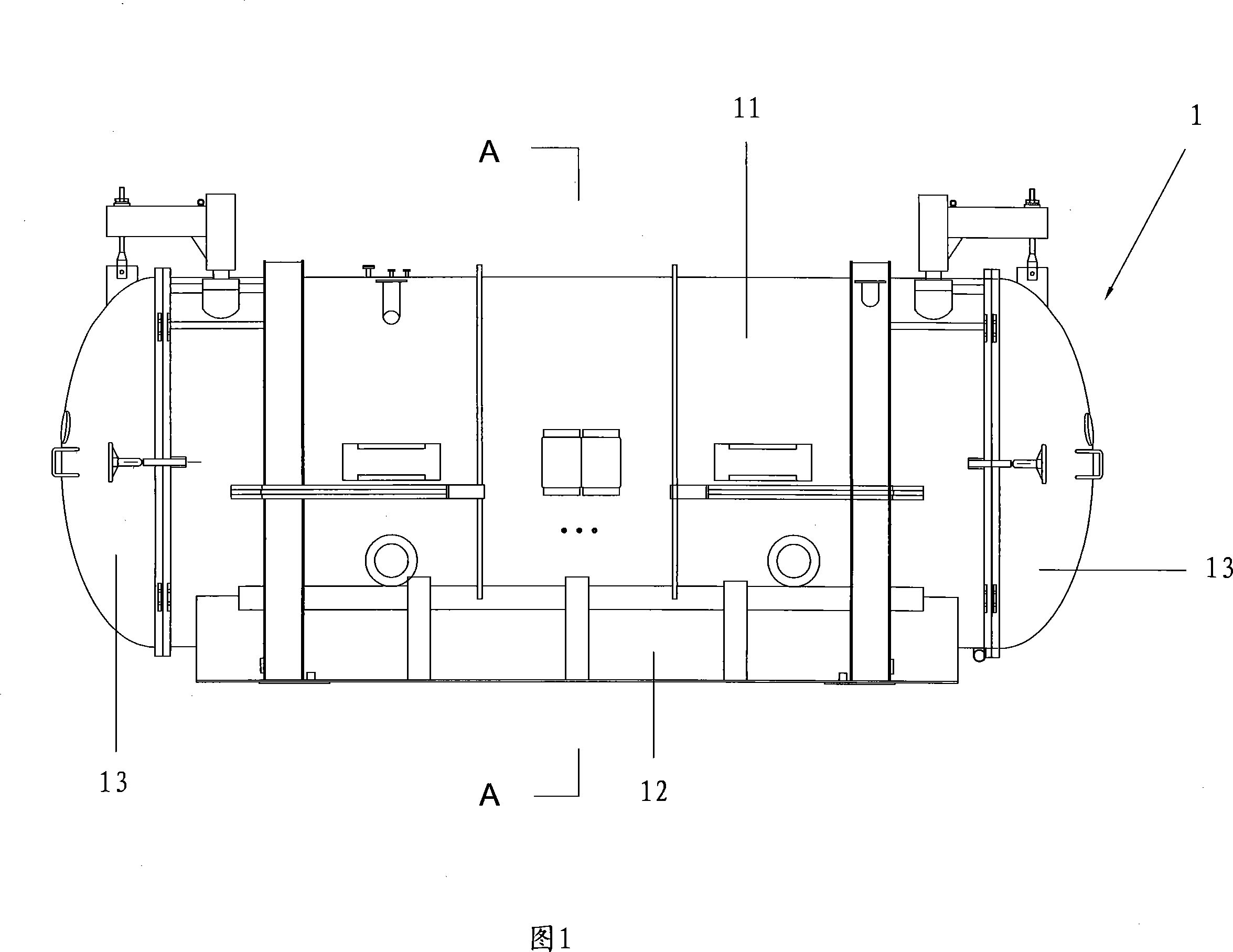

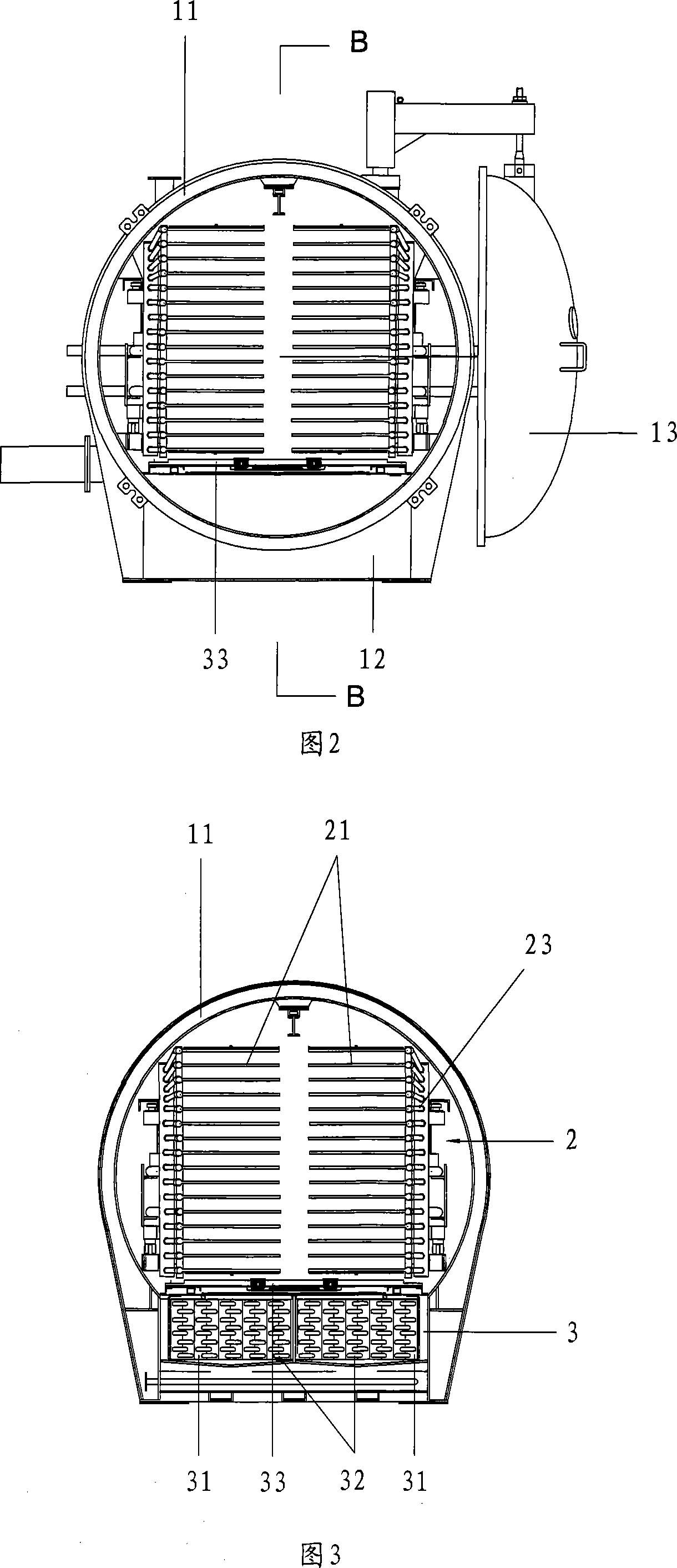

[0028] As shown in accompanying drawing 1, the vacuum freeze-drying cabin 1 that implements according to the present invention comprises horizontal cylindrical cabin 11, the square cabin 12 that is positioned at described cylindrical cabin 11 below, two front and back ends that are positioned at described drying cabin. Independent cabin door 13 respectively. The diameter of the cylindrical chamber is 2200 mm, which is 200 mm smaller than that of the prior art with similar production capacity, thus greatly reducing the vacuum volume.

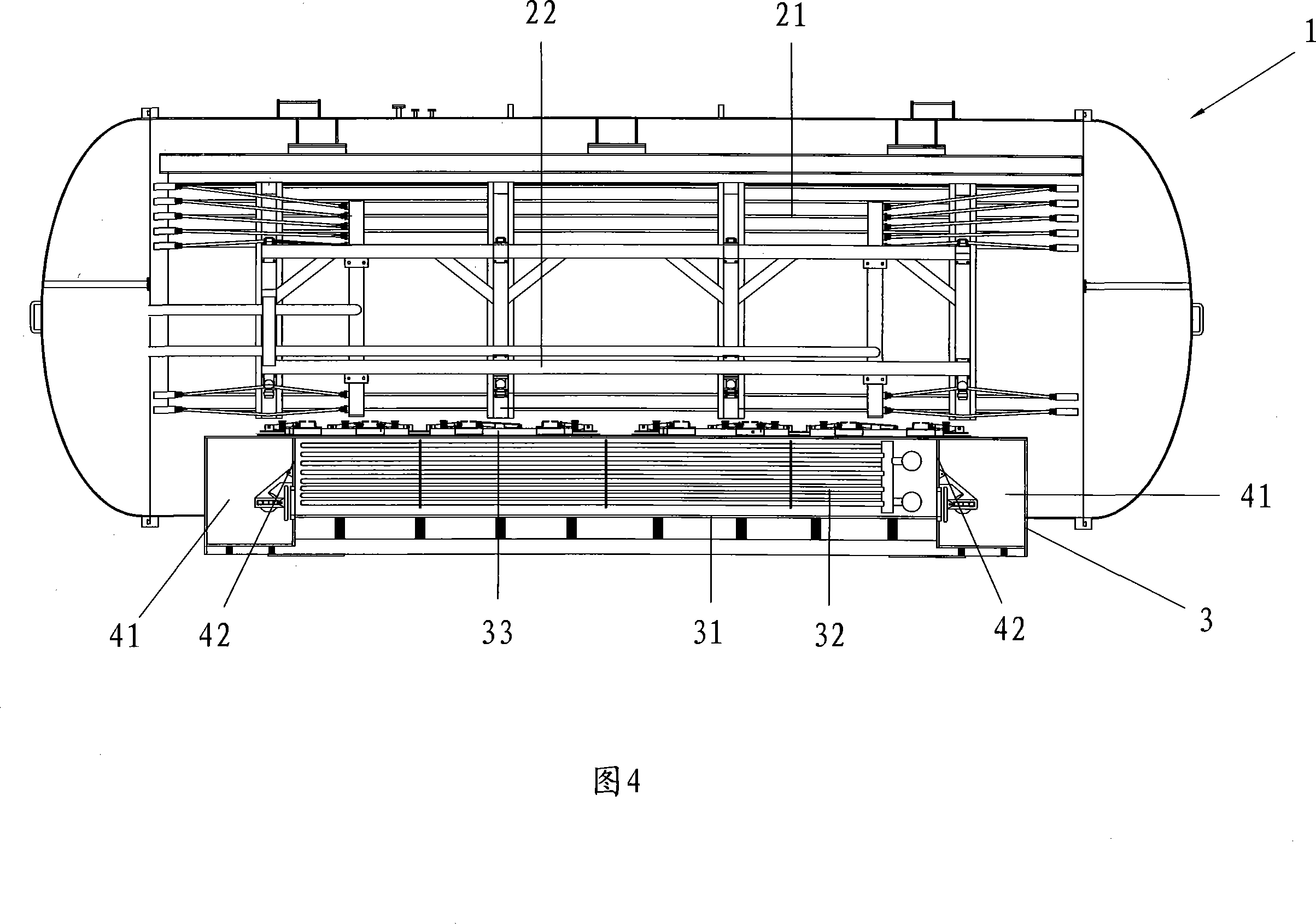

[0029] As shown in accompanying drawing 2 and accompanying drawing 3, in the inside of described cylindrical cabin 11, two groups of symmetrical heating plates 21 are arranged in parallel. The heating plate assembly 2 is removed. As shown in accompanying drawing 4, in the middle of heating plate 21, material frame 22 is arranged, and this material frame 22 is that can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com