Excitation method and exciter of double quality flywheel torsional oscillation

A dual-mass flywheel and torsional vibration technology, which is used in vibration testing, engine testing, and machine gear/transmission testing. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific examples, but the present invention is not limited.

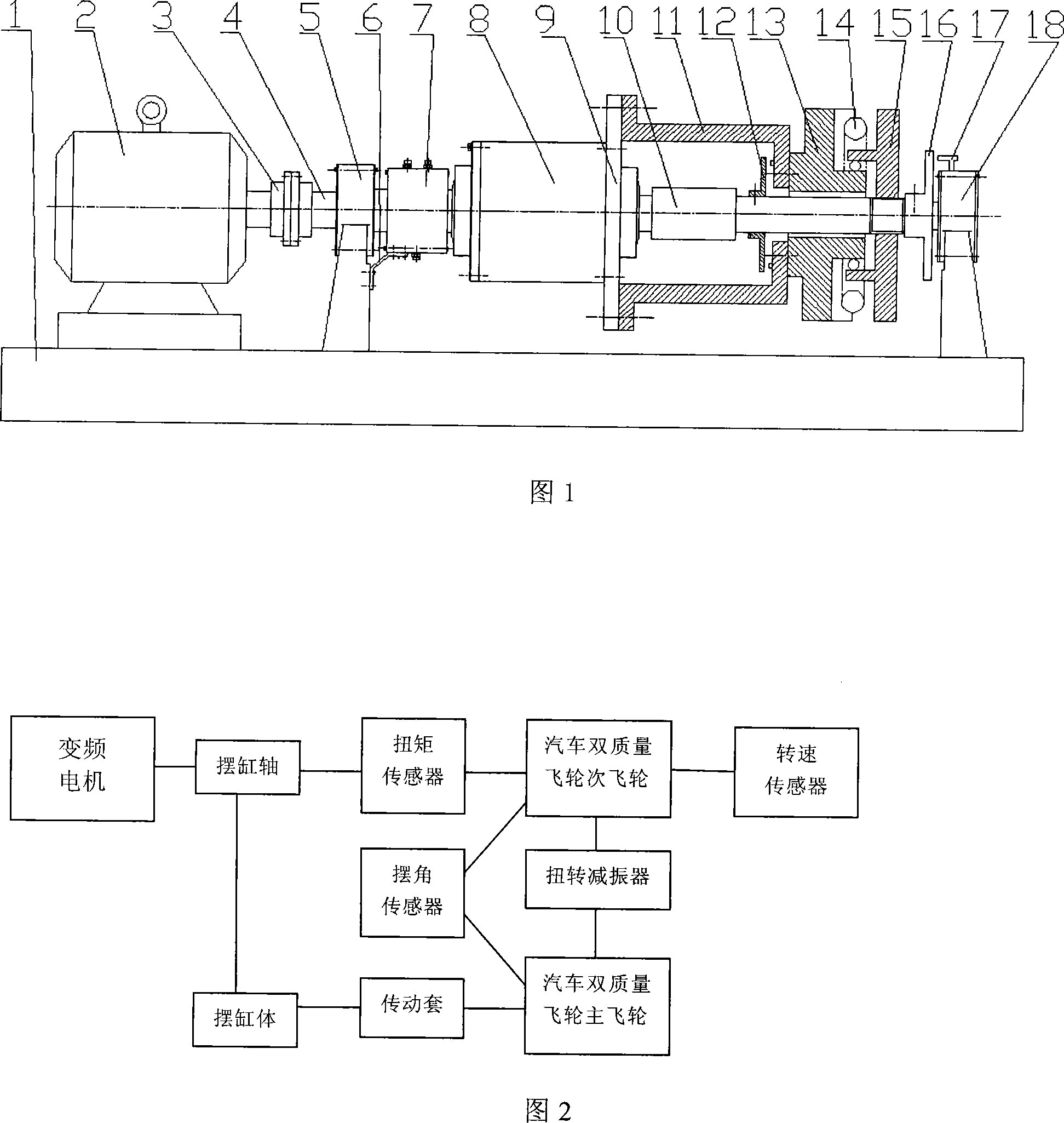

[0025] The method for exciting the torsional vibration of the dual-mass flywheel provided by the present invention is to adopt the method comprising the following steps to simulate the torsional vibration excitation of the engine during rotation:

[0026] (1) Simulation of rotating conditions:

[0027] The frequency conversion motor is used to drive the rotary hydraulic swing cylinder and the rotation of the dual-mass flywheel components to realize the simulation of the engine speed condition;

[0028] (2) Simulation of torsional vibration excitation conditions:

[0029] The rotary hydraulic swing cylinder is used to provide torsional motion between the main and secondary flywheels of the dual-mass flywheel, and the dual-mass flywheel to be tested is directly used as a necessary link for exciting torque transmission. The main and seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com