Special-shaped nozzle fluidics sprinkler

A full jet and nozzle technology, applied in the direction of spray device, spray device with movable outlet, etc., can solve the problems of no special-shaped nozzle nozzle structure to apply for patent, production cost is difficult to reduce, rocker springs work frequently, etc., to achieve simple structure, Improve reliability and work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

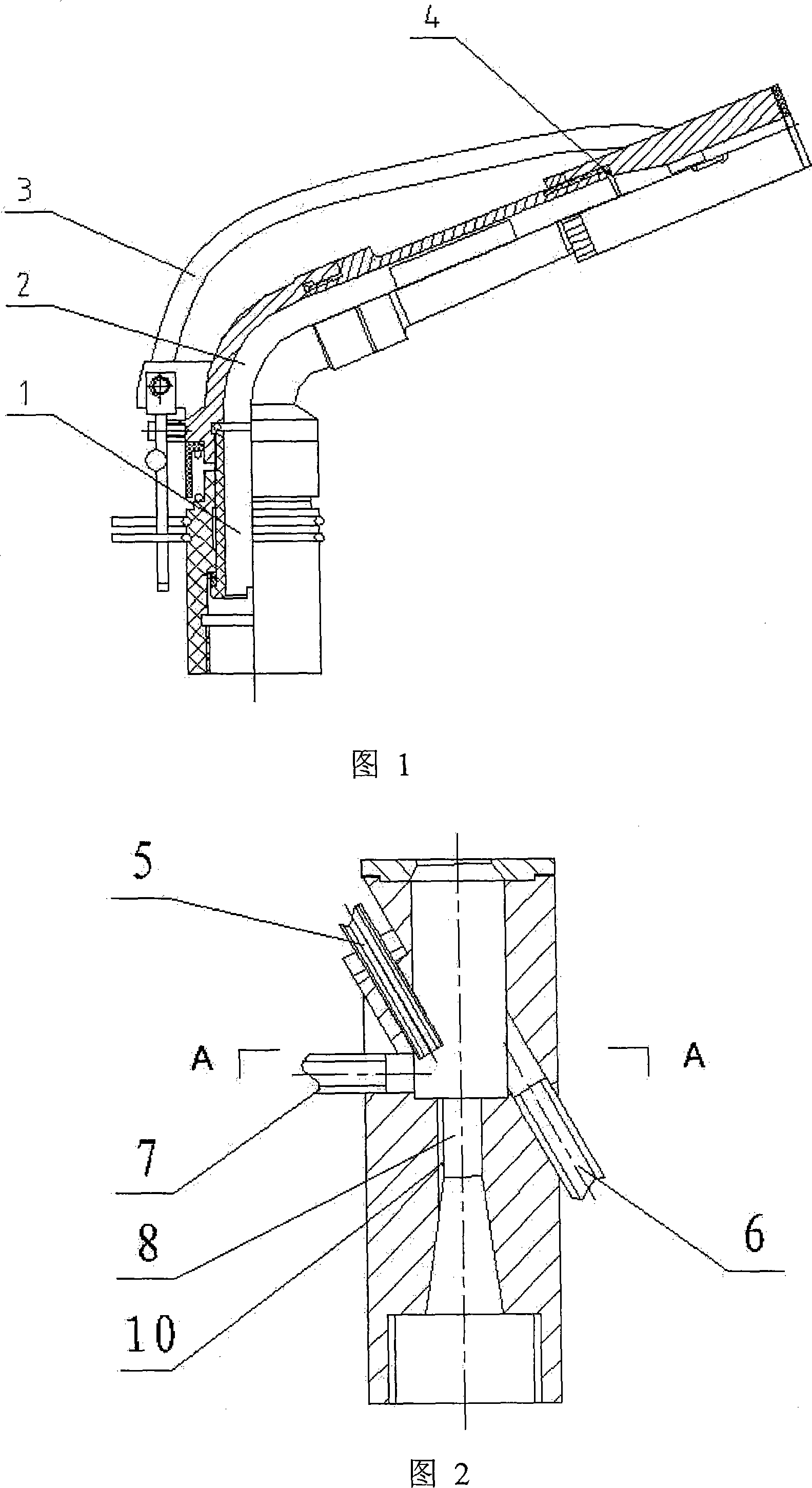

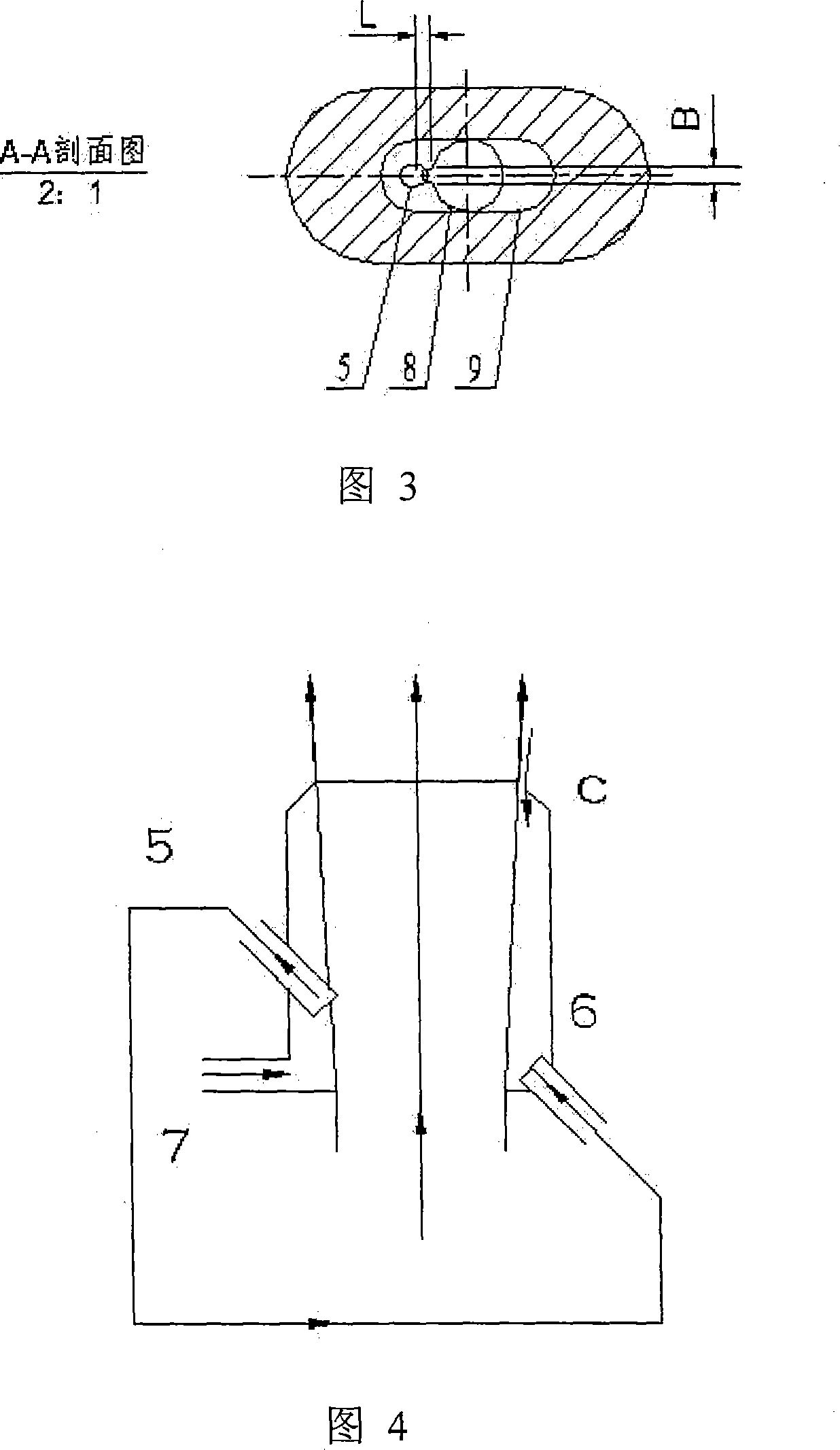

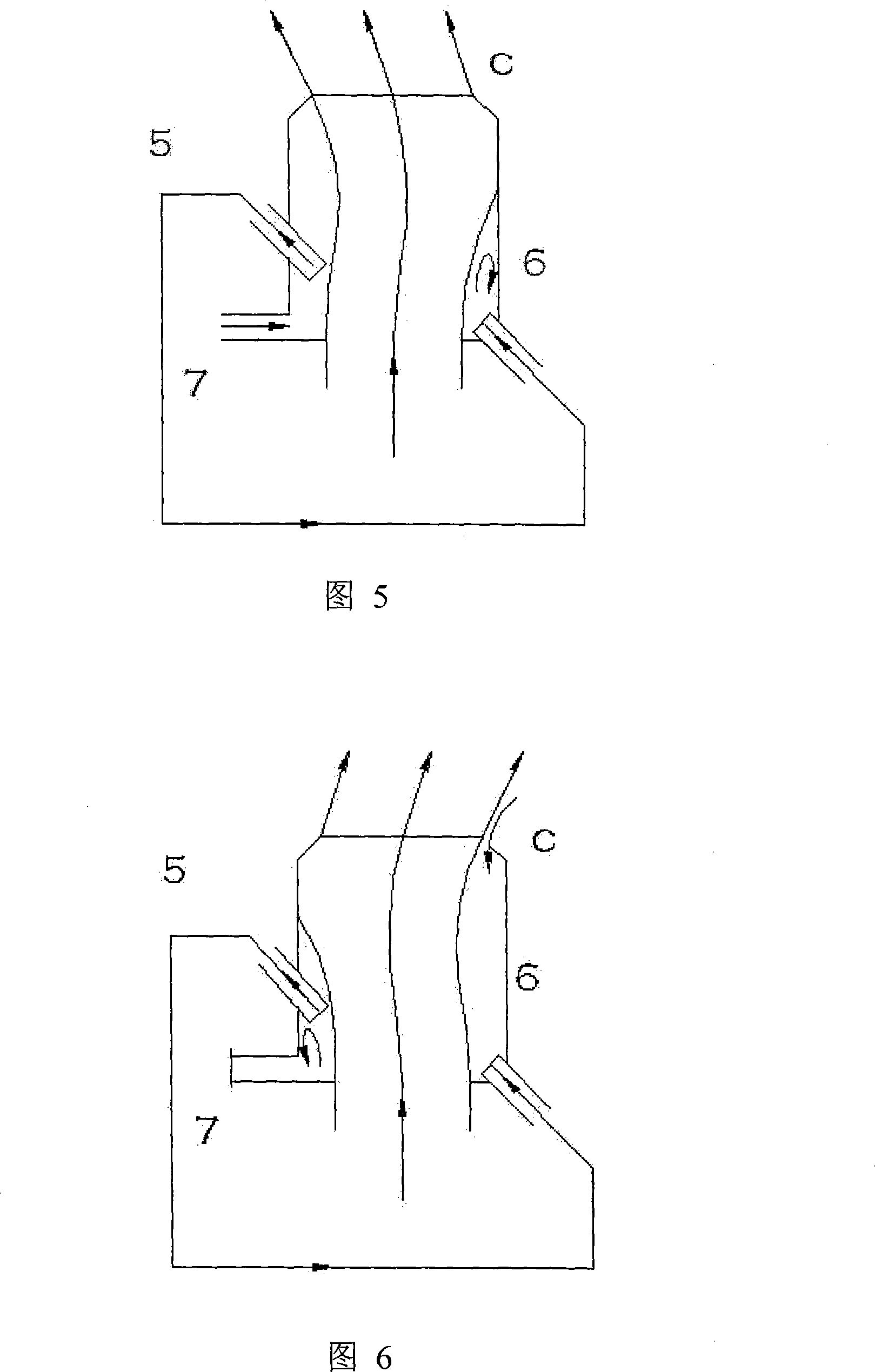

[0014] The special-shaped nozzle full-jet nozzle is composed of four parts: a rotary sealing mechanism (1), a flow channel (2), a reversing mechanism (3), and a special-shaped jet element body (4). The special-shaped jet element body is not only the nozzle outlet part of the spraying operation, but also the control part for automatic control to complete direct spraying, stepping and reverse. The special-shaped jet element body is composed of signal nozzle I (5), signal nozzle II (6), reverse nozzle (7), nozzle (8) and action area (9). Using the interception and flow of signal water in signal nozzle I (5) and signal nozzle II (6), the opening and closing of the reverse nozzle (7) realizes the wall attachment of the water flow, thereby completing the direct injection, stepping and reverse of the nozzle run. The nozzle of the special-shaped jet element body is non-circular, and the signal mouth 1 water intake position of the nozzle has a groove, and the groove can be arc-shaped,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com