Method for testing sulphates of tobacco by full-automatic chemical analyzer

An automatic chemistry and analyzer technology, applied in scientific instruments, analytical materials, instruments, etc., can solve the problems of increasing the probability of errors and cumbersome operation steps, and achieve the effects of reducing errors, good repeatability, and simplifying analysis steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

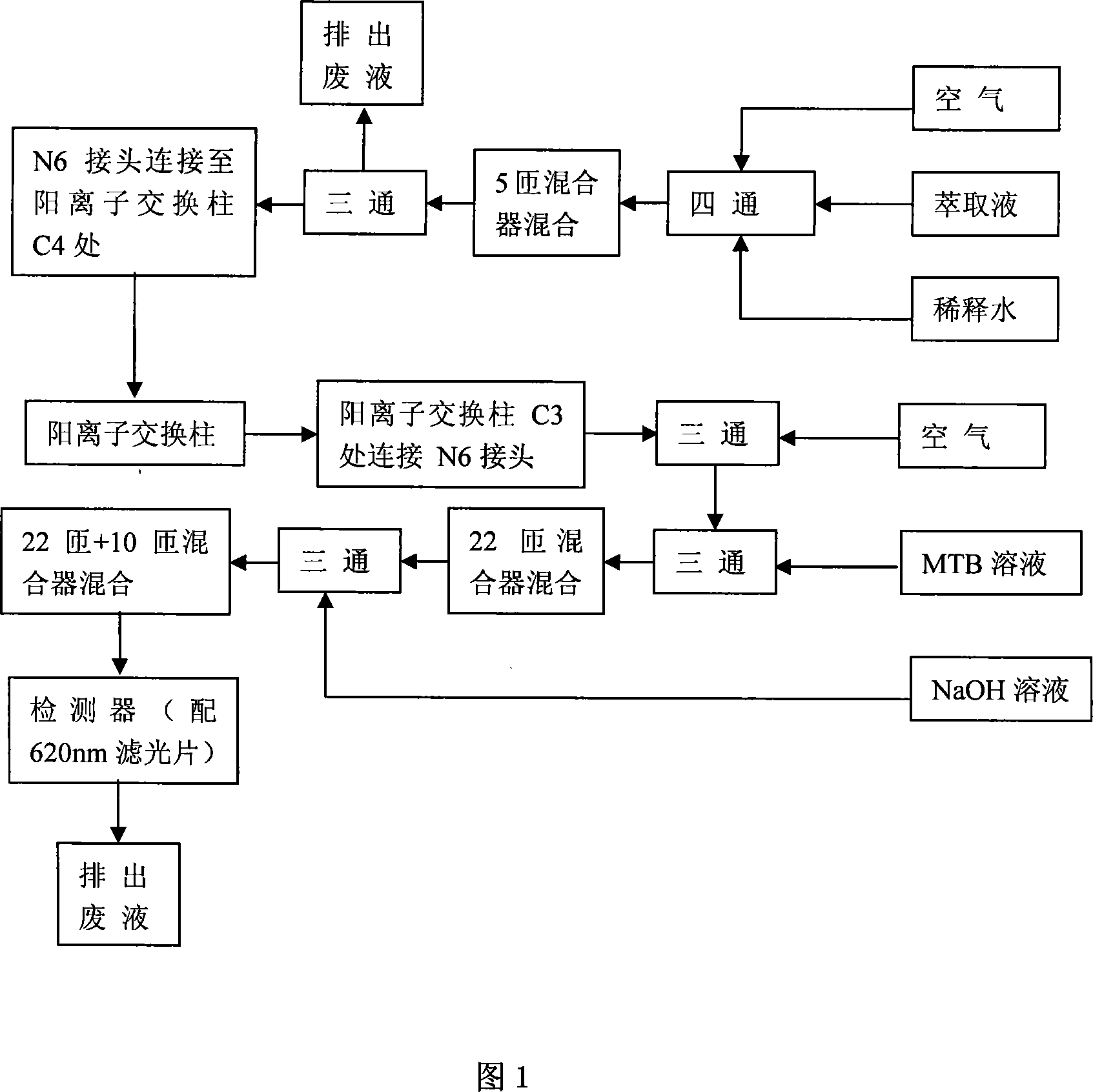

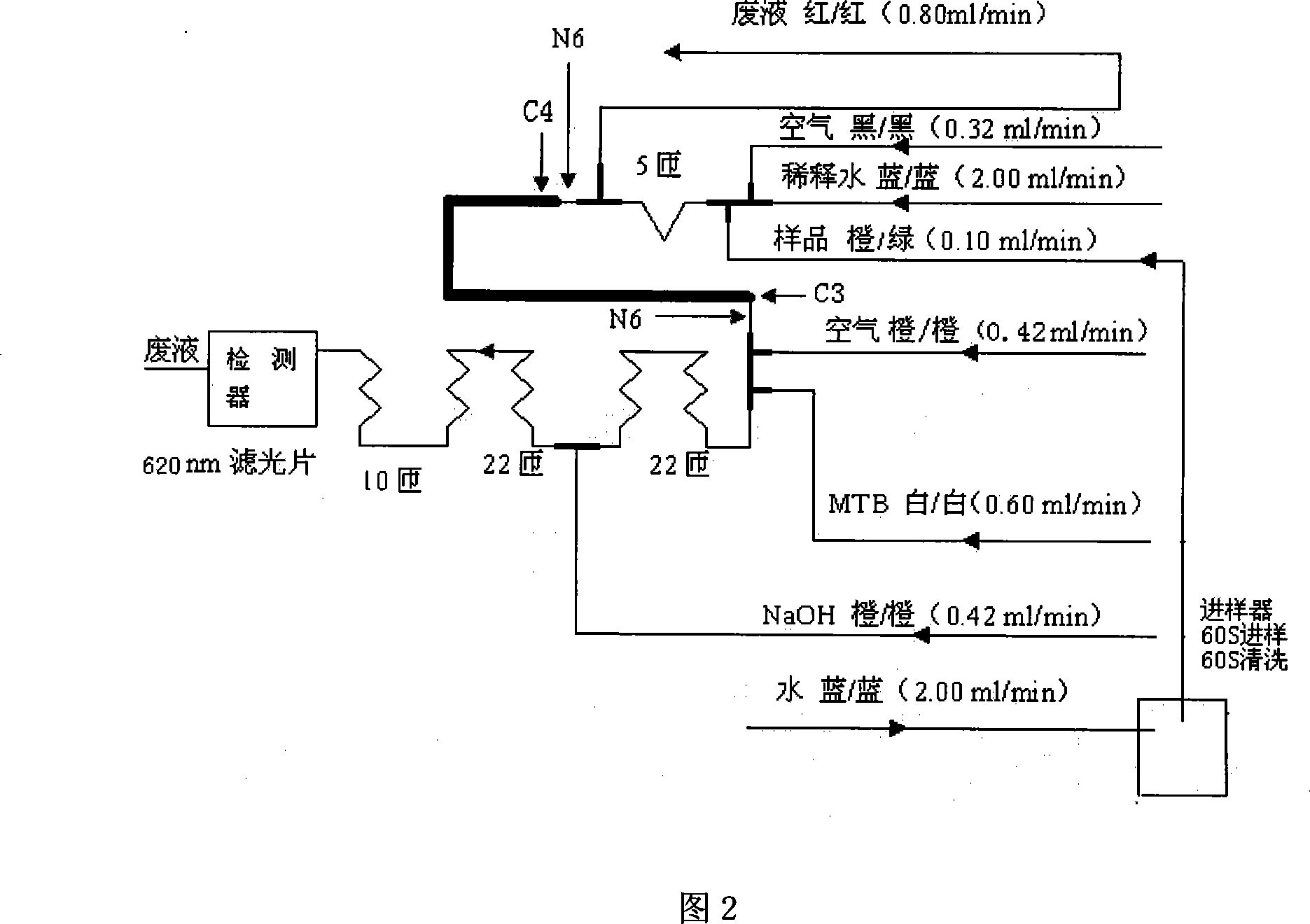

Method used

Image

Examples

Embodiment 1

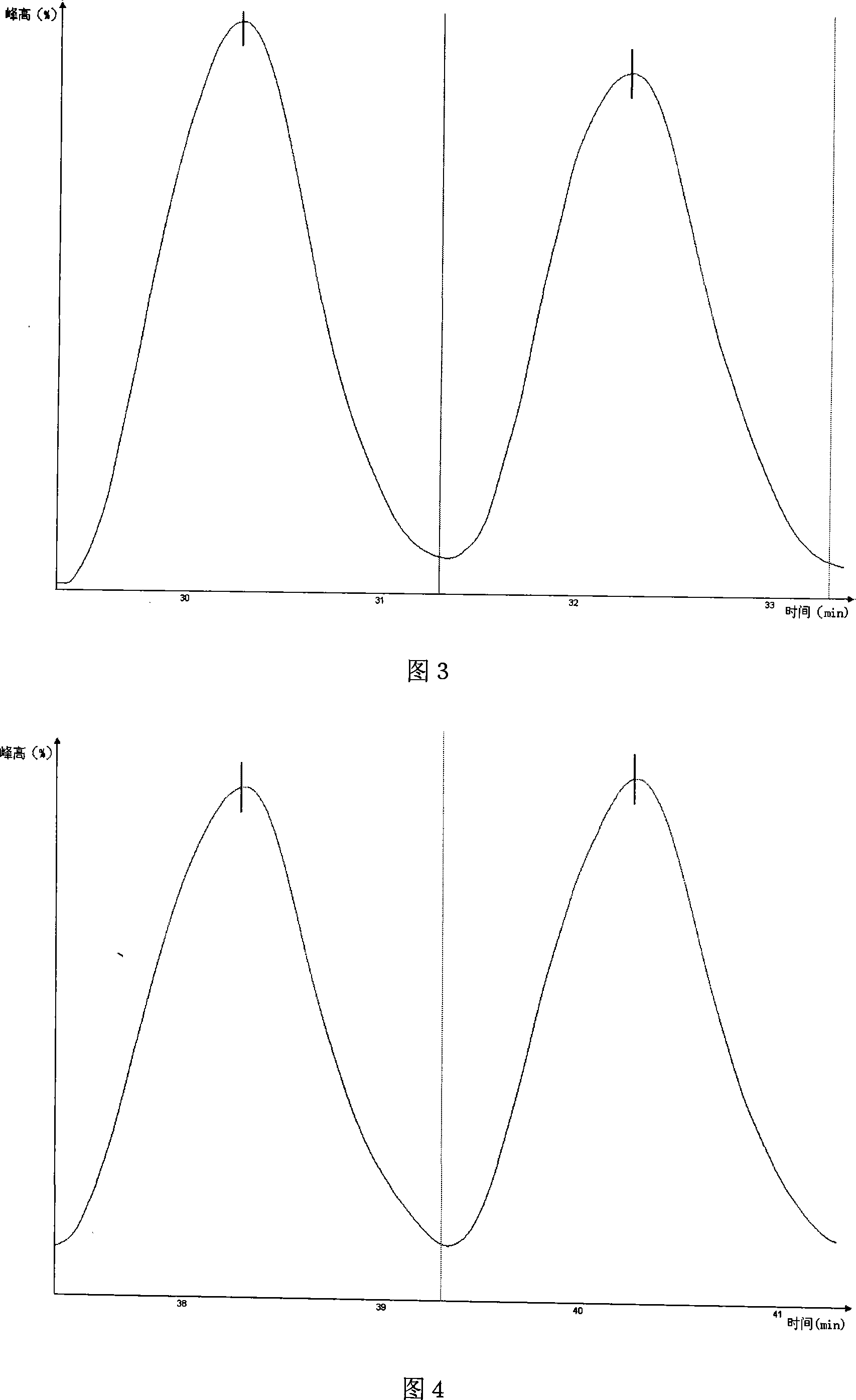

[0027] Example 1: Determination of sulfate in flue-cured cigarettes.

[0028] (1) Preparation of test solution

[0029] Accurately weigh 0.25g of tobacco sample into a 50mL Erlenmeyer flask with a stopper, add 25mL of deionized water, shake on a shaker for 40min, filter with rapid qualitative filter paper, discard the first few milliliters of filtrate, and collect the rest for later use.

[0030] (2) Standard solution configuration

[0031] Prepare standard stock solution A with baked sodium sulfate standard product: Weigh 14.7921g of sodium sulfate in a beaker, accurate to 0.0001g, dissolve with deionized water, transfer to a 1000mL volumetric flask, and dilute to the mark with deionized water . The concentration of standard stock solution A is: 9.9003mg / mL (as SO 4 2- concentration meter). (Calculation method: SO in sodium sulfate 4 2- The content is (96 / 142)×100%, the concentration of standard stock solution A is: 14.7921×(96 / 142)×99.9 (purity of sodium sulfate)×1000...

Embodiment 2

[0077] Example 2: Determination of sulfate in mixed cigarettes.

[0078] (1) Preparation of test solution

[0079] Accurately weigh 0.25g of tobacco sample into a 50mL Erlenmeyer flask with a stopper, add 25mL of deionized water, shake on a shaker for 40min, filter with rapid qualitative filter paper, discard the first few milliliters of filtrate, and collect the rest for later use.

[0080] (2) Standard solution configuration

[0081] Prepare standard stock solution A with baked sodium sulfate standard product: Weigh 14.7921g of sodium sulfate in a beaker, accurate to 0.0001g, dissolve with deionized water, transfer to a 1000mL volumetric flask, and dilute to the mark with deionized water . The concentration of standard stock solution A is: 9.9003mg / mL (as SO 4 2- concentration meter).

[0082] Standard stock solution B: Pipette 10mL of standard stock solution A into a 100mL volumetric flask, and dilute to the mark with deionized water. The concentration of standard sto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com