Magnetic transmission fluent metal magnetofluid wave energy direct electricity generation unit device

A magnetic fluid power generation and liquid metal technology, applied in electromechanical devices, ocean energy power generation, electrical components, etc., can solve the problems of difficulty in generating induced electromotive force, destroying flow channel seals, reducing energy conversion efficiency, etc., and achieving easy commercialization. , High conversion efficiency, the effect of improving energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

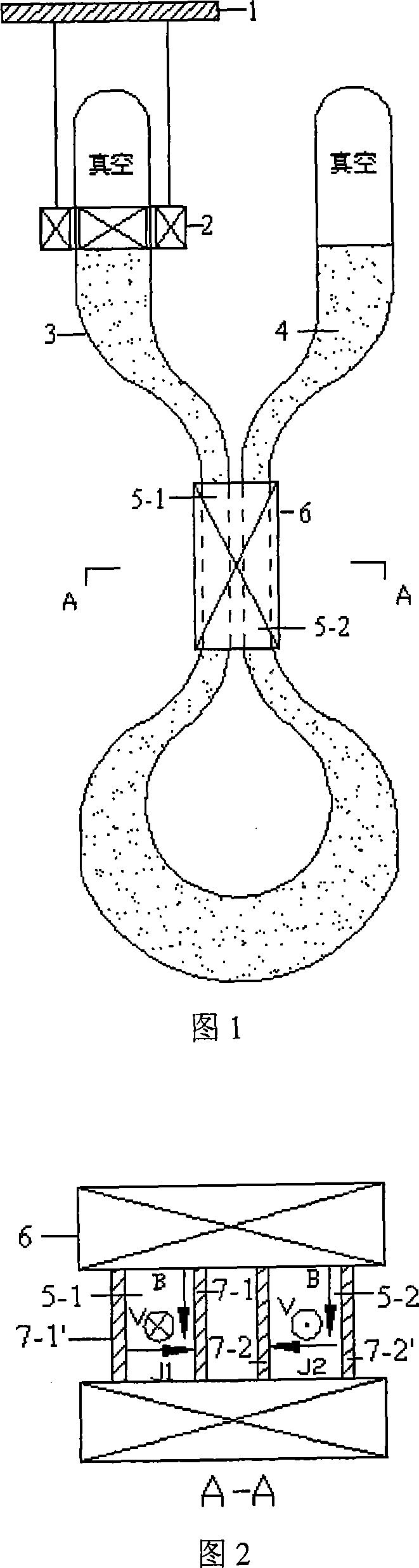

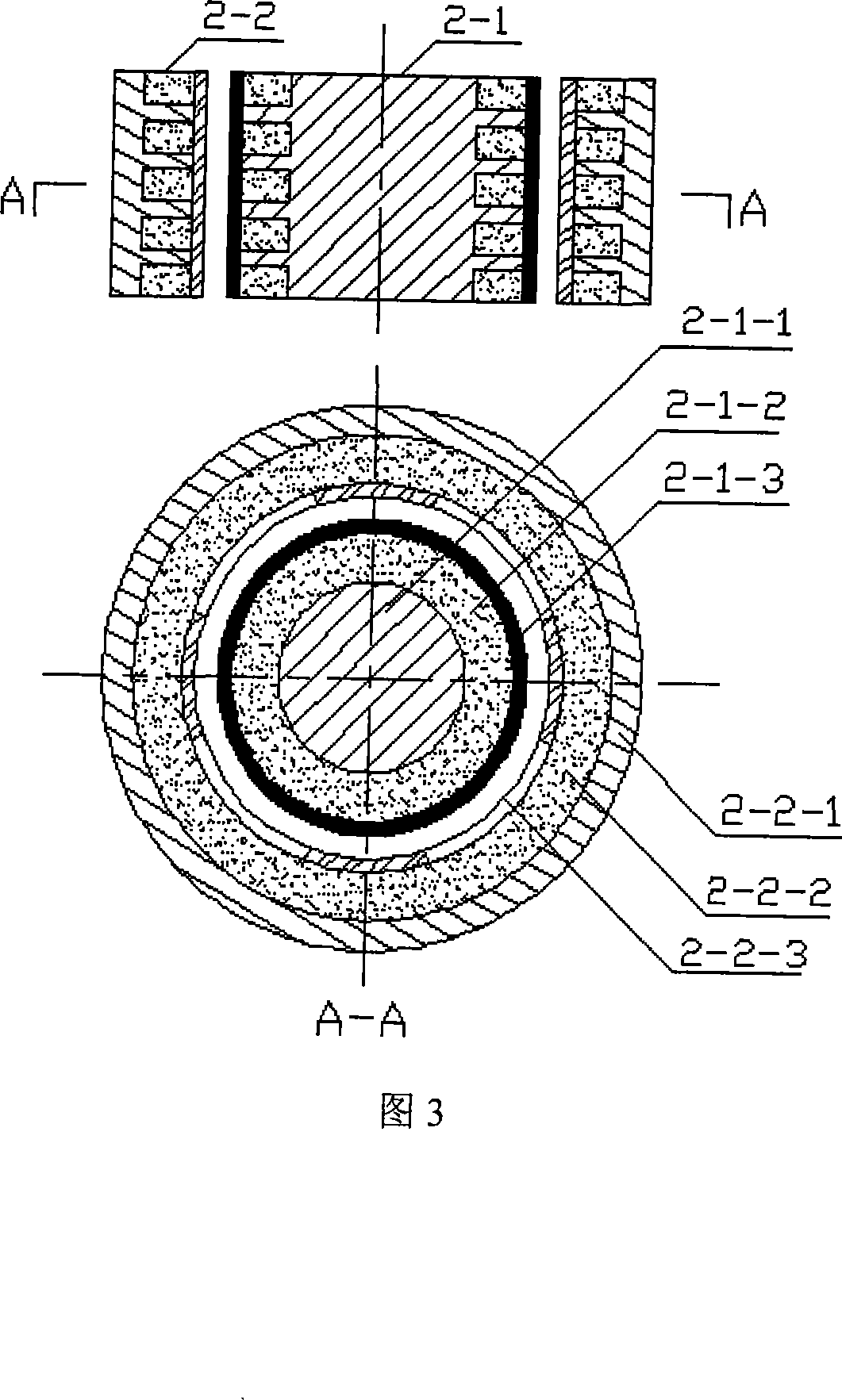

[0017] Fig. 1 is a schematic structural diagram of a specific embodiment of the present invention. As shown in Figure 1, the specific embodiment of the present invention consists of a pressure plate 1, a magnetic coupling piston 2, a U-shaped sealed pipeline 3 equipped with liquid metal 4, a left channel 5-1 for magnetic fluid power generation, and a right channel 5-2 for magnetic fluid power generation Composed of two pole magnets 6, vertically arranged in seawater near the sea surface.

[0018] The U-shaped sealed pipeline 3 is a sealed pipeline space made of non-magnetic and non-conductive materials, and the two ends are vacuum; it consists of left and right straight line sections, left and right tapered sections, magnetic fluid power generation left channel 5-1 and The right passage 5-2 and the annular section are composed, and the liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com