Oil-containing sewage treatment system

A treatment system and technology for oily sewage, applied in biological water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as the inability to reduce the COD of sewage and the inability of water to directly meet the standard discharge, etc. Achieve the effect of low cost, reasonable structure and enhanced reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

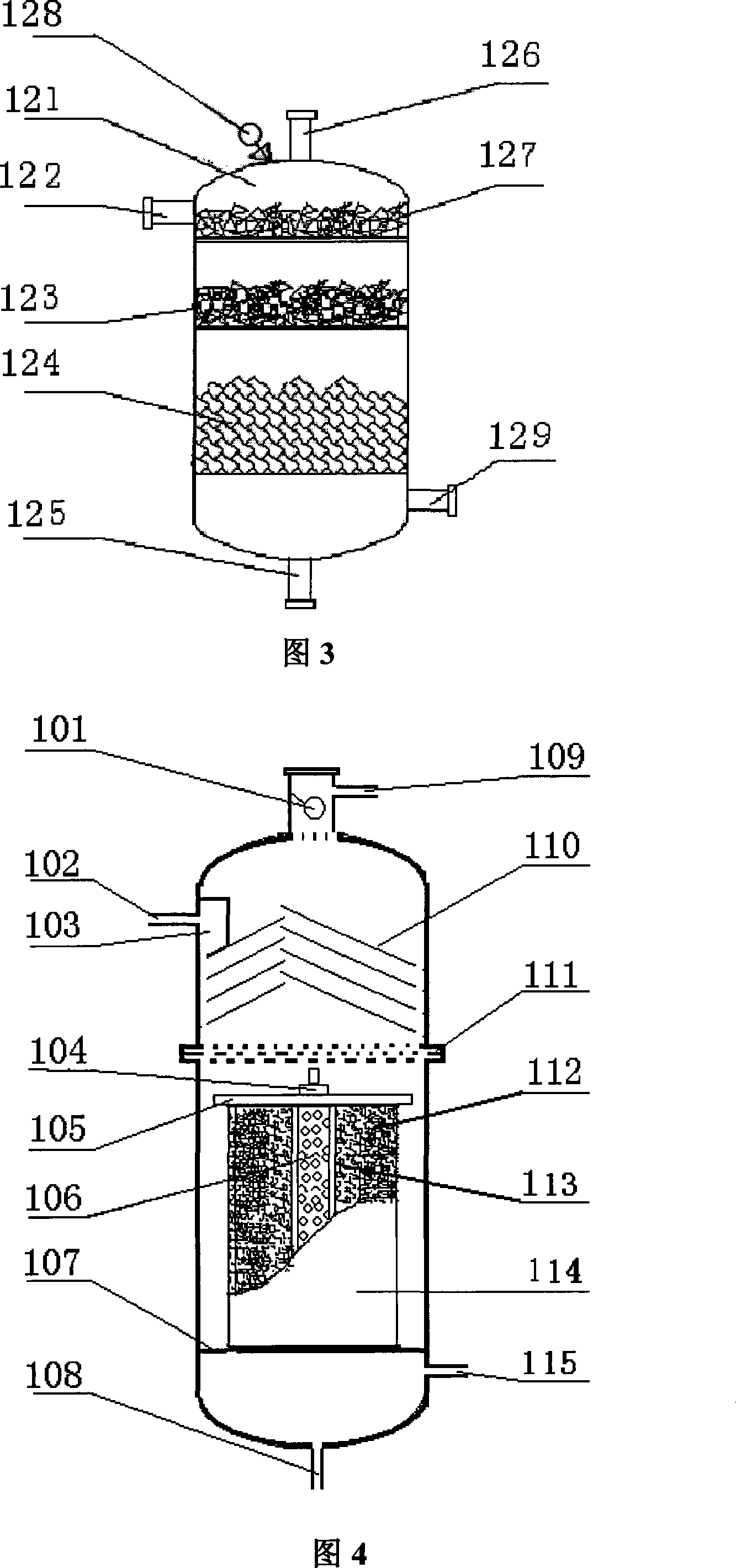

[0030] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and any similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

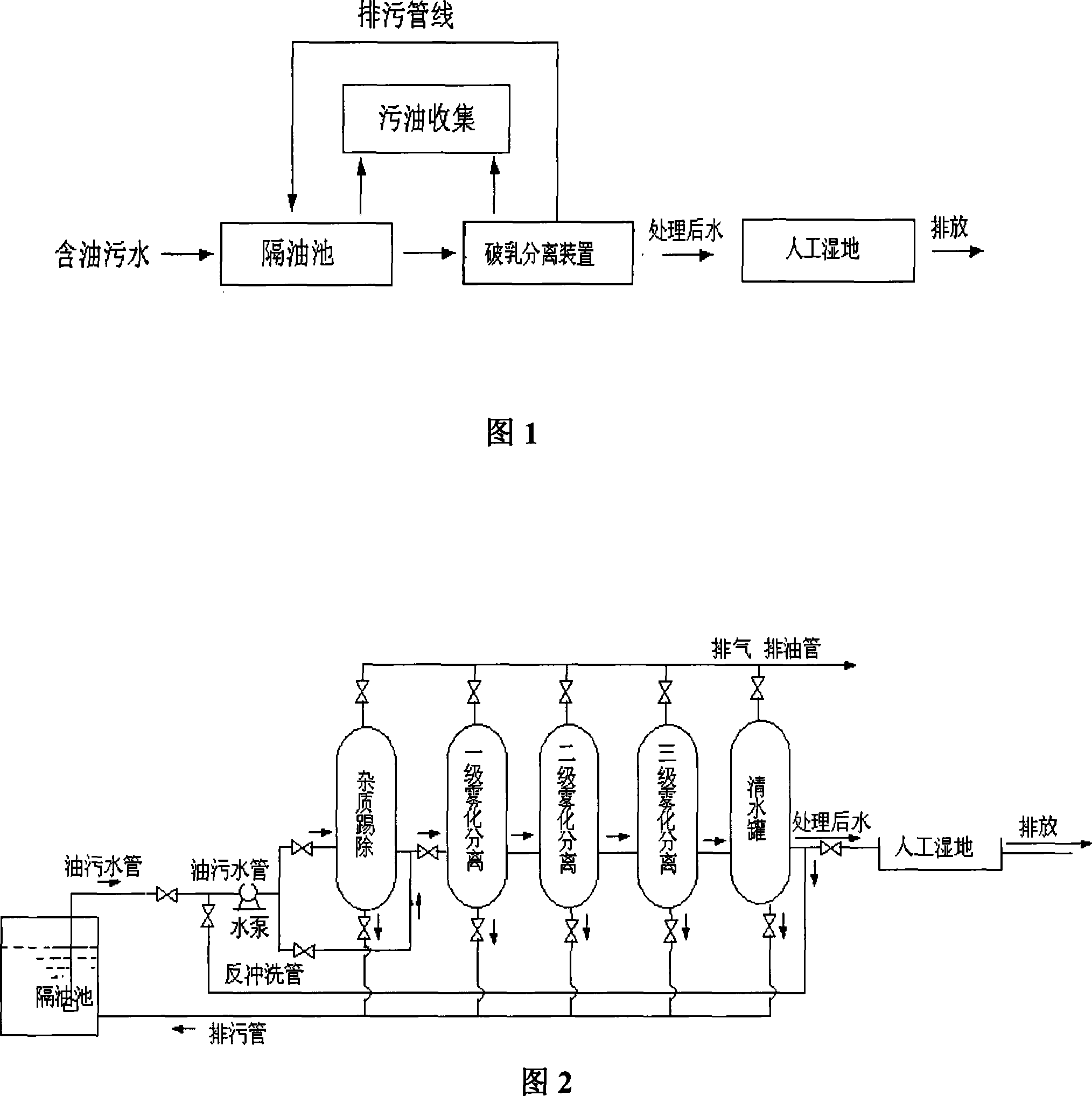

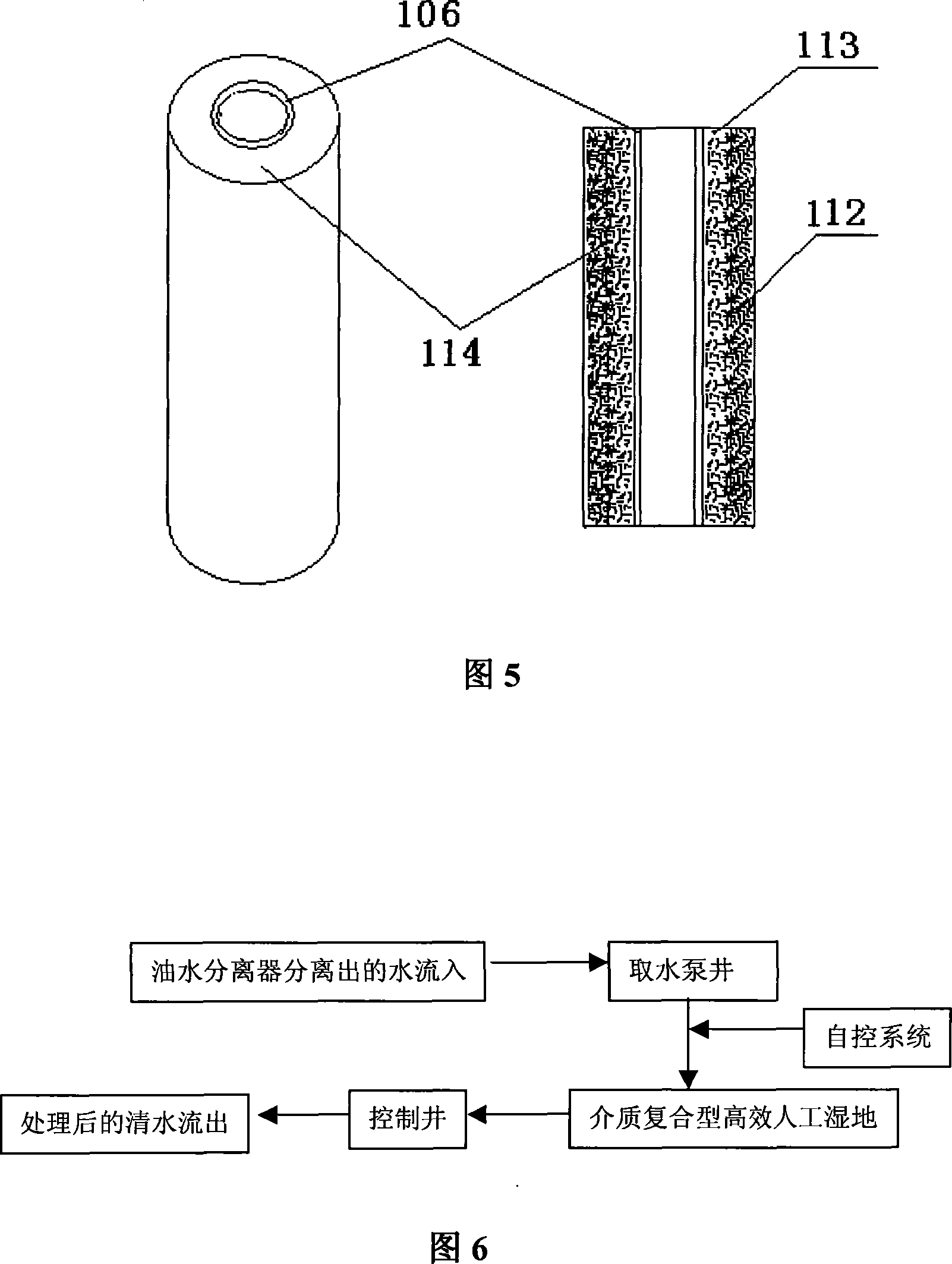

[0031] Referring to shown in Fig. 1, the flow process of a kind of oily sewage treatment system of the embodiment of the present invention: 1) oil separation, oily sewage enters grease trap; Removed, it is collected as dirty oil, and solid impurities are deposited at the bottom of the grease trap; in the last stage of the grease trap, most of the suspended matter and oily matter in the oily sewage are removed, and there are It is beneficial to the use of the oil-water separator in the next stage to prevent and reduce clogging; 2) oily sewage treatment, the oily sewage enters the demulsification separation device for impurity re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com