A method for treating oily sludge

A sludge treatment and sludge technology, applied in the fields of sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. The effect of rapid oil-water separation and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

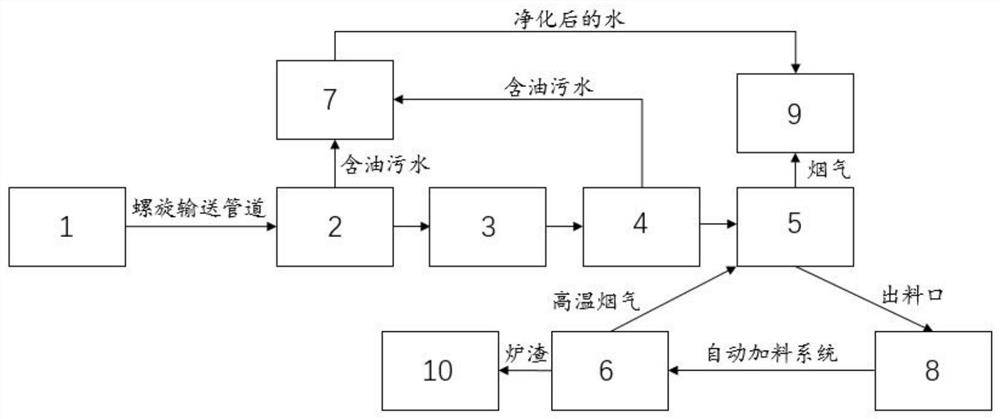

[0035] Such as figure 1 As shown, it is a schematic block diagram of the process flow of the equipment for treating oily sludge of the present invention. The equipment for treating oily sludge of the present invention consists of a first stirring system 1, a mechanical dehydration system 2, an oily sewage treatment system 7, and a second stirring system. System 3, solid-liquid separation system 4, drying device 5, gas treatment system 9, brick making system 10 and granulation system 8; the discharge port of the first mixing system 1 is connected with the mechanical dehydration system 2 through the spiral conveying pipeline Connection; the mud outlet of the mechanical dehydration system 2 is connected to the second mixing system 3, and the water outlet of the mechanical dehydration system 2 is connected to the oily sewage treatment system 7; the outlet of the second mixing system 3 is connected to the solid-liquid separation device 4, and the solid-liquid separation The water o...

Embodiment 2

[0041] Utilize the repairing agent described in embodiment 1 and the using method of the using equipment of the repairing agent of the oily sludge treatment of equipment, comprise the following several steps:

[0042] (1) Preparation of repairing agent: according to parts by weight, get 30 parts of 400-mesh quicklime, 10 parts of 400-mesh calcium oxide, 20 parts of 400-mesh magnesium oxide, 15 parts of 400-mesh volcanic ash, 5 parts of 800-mesh graphene; Calcium activity ≥ 95%, use dry material mixing equipment, input in proportion, mix well, and then get the repair agent;

[0043] (2) Pre-stirring treatment: Put the oily sludge into the first mixing system for pre-stirring and heat up to 20°C, add repairing agent, the mass ratio of repairing agent to sludge is 0.5:10, maintain its temperature, and perform ultrasonication on it Treatment, ultrasonic treatment includes low-frequency ultrasonic treatment and high-frequency ultrasonic treatment, the frequency of low-frequency ult...

Embodiment 3

[0053] Utilize the repairing agent described in embodiment 1 and the using method of the using equipment of the repairing agent of the oily sludge treatment of equipment, comprise the following several steps:

[0054] (1) Preparation of restoration agent: according to parts by weight, get 25-35 parts of 400-mesh quicklime, 5-15 parts of 400-mesh calcium oxide, 15 parts of 400-mesh magnesium oxide, 10 parts of 400-mesh volcanic ash, and 3 parts of 800-mesh graphene ; Wherein, the activity of calcium oxide is more than 95%, using dry material mixing equipment, inputting in proportion, and mixing to obtain the restoration agent;

[0055] (2) Pre-stirring treatment: put the oily sludge into the first stirring system for pre-stirring and heat up to 30°C, add repairing agent, the mass ratio of repairing agent to sludge is 0.8:9, maintain its temperature, and perform ultrasonication on it Ultrasonic treatment, ultrasonic treatment includes low-frequency ultrasonic treatment and high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com