Cardboard silver-coating printing technique for cigarette packet

A technology for cardboard and cigarette case, applied in the field of cardboard transfer silver-coated printing process, can solve the problems of unfavorable environmental protection, difficult recycling, high cost, and achieve the effects of saving packaging cost, strong adhesion, and easy degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

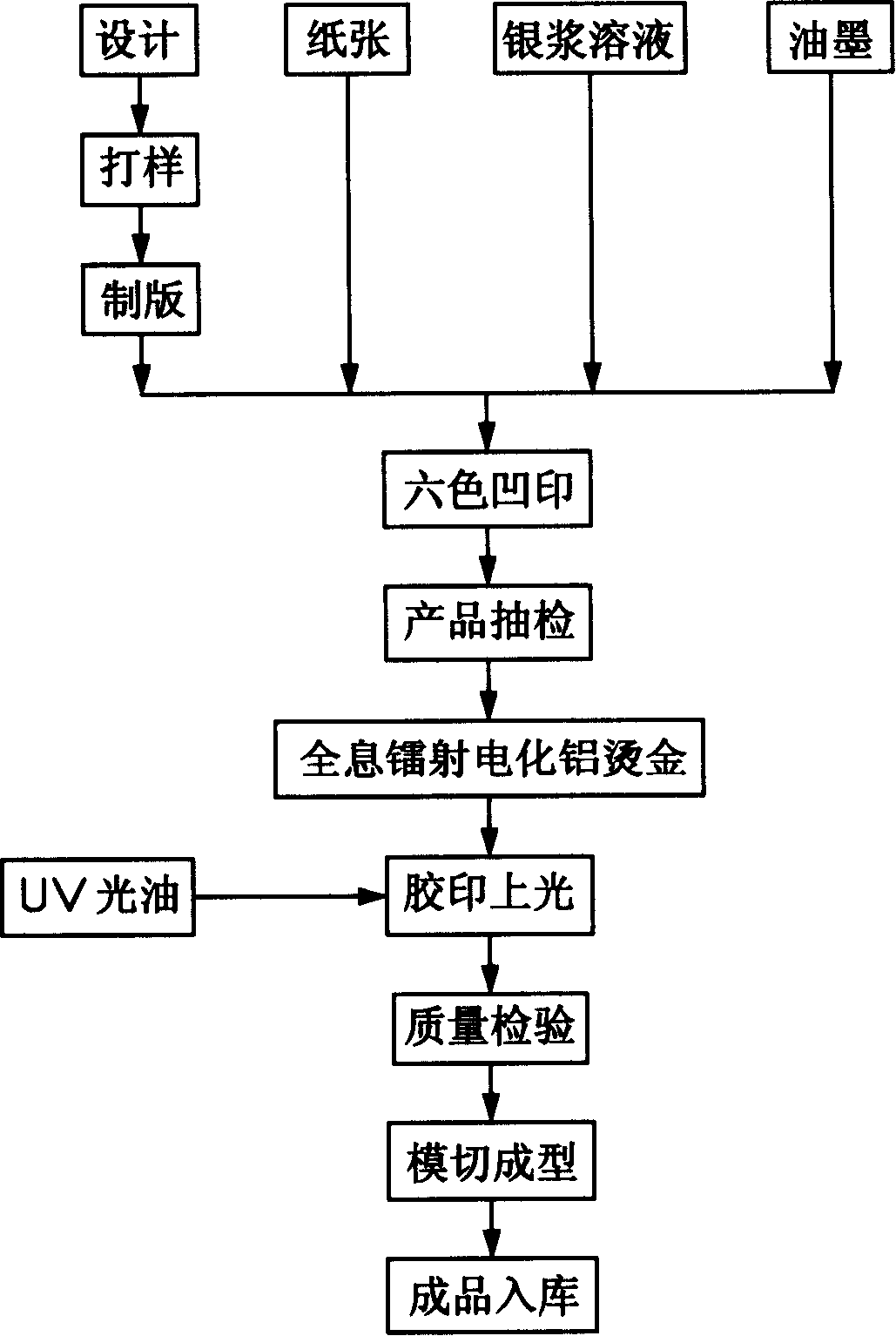

[0015] Refer below figure 1 A specific embodiment of the present invention will be described.

[0016] refer to figure 1 , the production process of this embodiment is as follows:

[0017] 1. Prepress preparation.

[0018] The low-cost and environmentally friendly white cardboard is used instead of gold cardboard as the cigarette label packaging material, achieving the same effect as printing on gold cardboard. At present, most middle and high-end cigarette labels use gold cardboard as the packaging material, and use the characteristics of gold cardboard surface gloss, high smoothness, and good color rendering effect to display better printing grades, but because the cost of gold cardboard is relatively high High, and the surface film, poor degradability, not easy to recycle. In order to return to packaging positioning, reduce packaging costs, and promote green and environmentally friendly packaging, white cardboard is used instead of gold cardboard as the cigarette label ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com