Asphalt mixture regenerating heating stirring roller

A technology of asphalt mixture and drum, which is applied in the field of concrete mixing, and can solve the problems of aggregate particle size reduction, gradation damage, powder increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

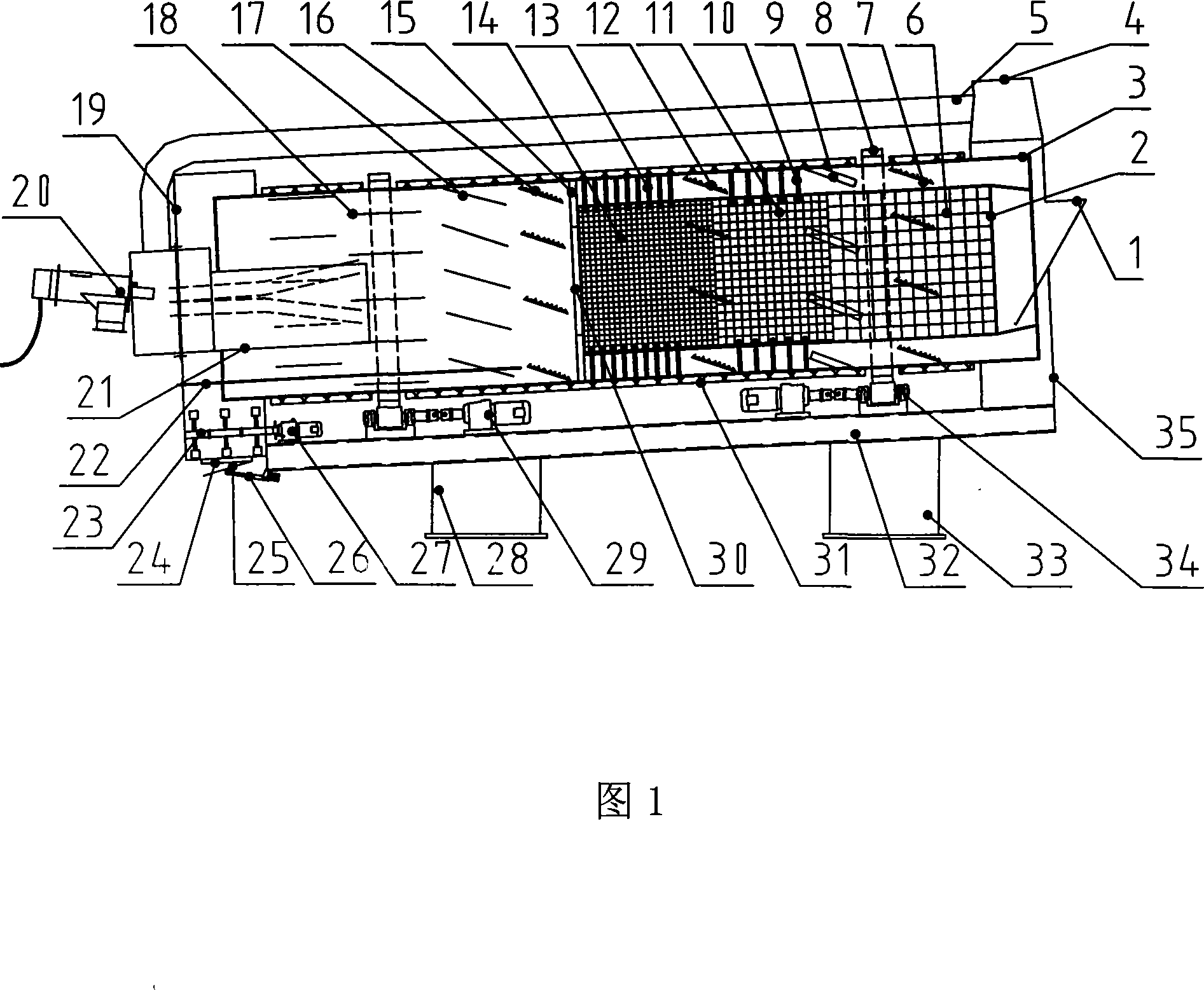

[0013] As shown in Figure 1, the asphalt mixture regeneration heating and mixing drum has an inclined drum support 32 supported by the front leg 33 and the rear leg 28. The outer layer of the drum 3 is wrapped with an insulating layer 31. The two rolling rings 8 and the rollers matched with the rolling rings 8 are arranged on the drum bracket 32, and the drum front driving device 34 and the drum rear driving device 29 on the drum bracket drive the drum 8 to rotate, thereby driving the drum to rotate together. The feed port 1 is located at the higher end of the drum 3 , the drum at the upper position of the feed port 1 is provided with a flue gas outlet 4 , and the lower end of the drum is provided with a burner 20 . The inner screening drum 2 is set inside the drum at the end of the feeding port, and the inner screening drum 2 is fixedly connected with the drum 3. The outer peripheral wall of the inner screening drum is composed of a screening mesh, and the inner end of the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com