Drilling jig for unitized tooling circumferential and axial bore of electrohydraulic servo valve cover plate

An electro-hydraulic servo valve and combined processing technology, which is applied in the direction of drilling molds for workpieces, can solve the problems of large processing position errors, and achieve the effects of ensuring processing accuracy, simple structure, and good operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

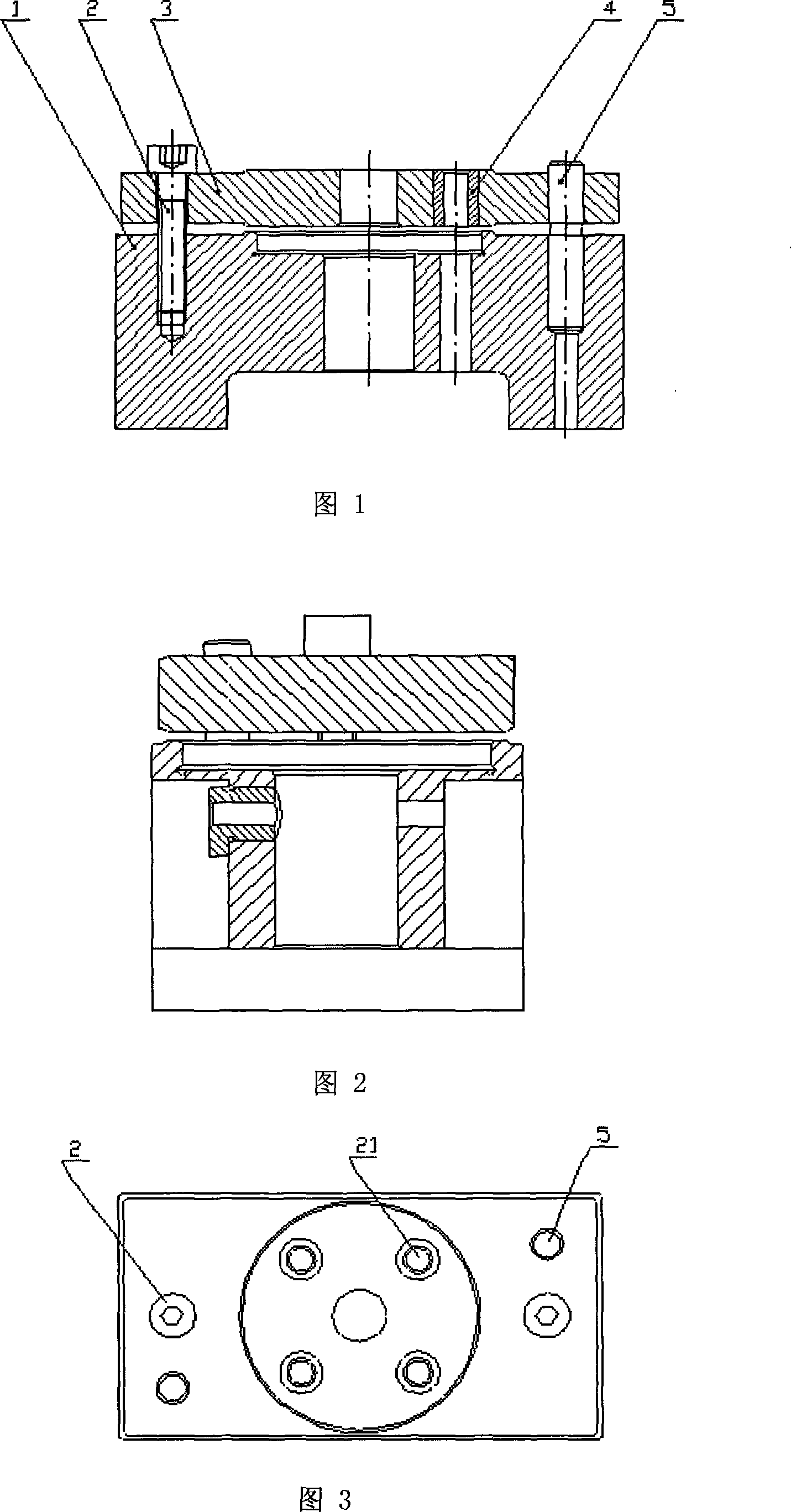

[0019] As shown in Fig. 1 to Fig. 4, the drilling template for combined processing of the electro-hydraulic servo valve cover plate circumferential and axial holes of the present invention is shown in the figure, which includes a drilling template body (bottom plate), a drilling template and a special-shaped drill sleeve etc., where:

[0020] The described drilling template body (bottom plate) 1 is a rectangular block, and the side is equipped with a drill bushing 6 that is cut into a fan shape, and two positioning pins 5 are installed on the top surface, and its two ends are not matched. The workpiece is placed on the drilling template body 1 The positioning hole positioning;

[0021] A fixed drill bushing 4 is housed on the described drilling template 3, and the whole drilling template assembly is combined with the drilling template body 1 through the positioning pin shaft 5 and the hexagon socket head cap screw 2 and compresses the workpiece.

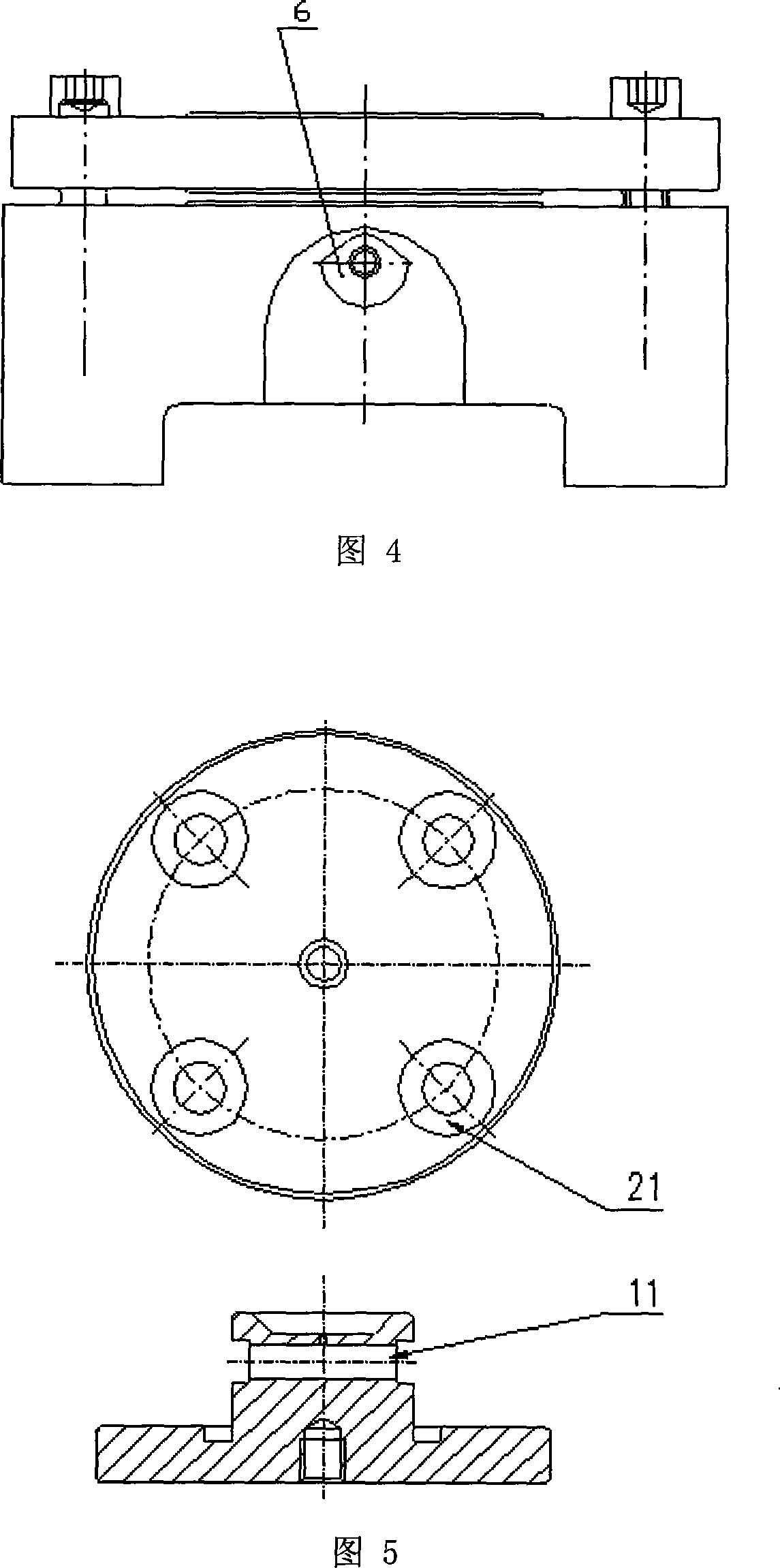

[0022] As shown in Figure 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com