Numeralization integrated impulsing power source chip

A pulsed power supply and chip technology, applied in circuits, electric processing equipment, metal processing equipment, etc., can solve the problems of single function, rough surface of processed workpiece, poor anti-interference ability, etc., achieving a high degree of integration, various processing forms, Strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

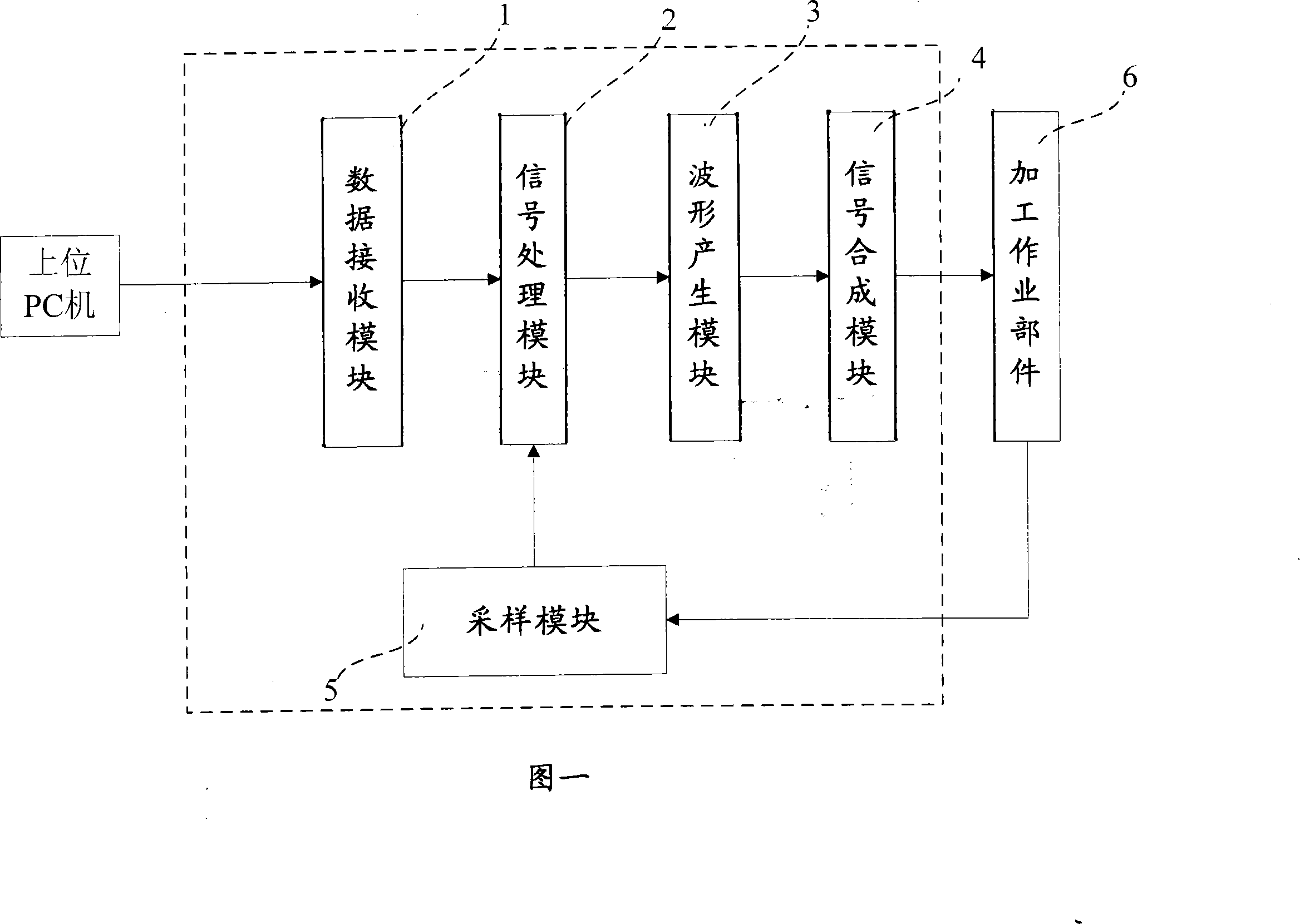

[0028] A digital integrated pulse power supply chip, which includes a data receiving module 1 for receiving a first set of parameter signals from an upper PC;

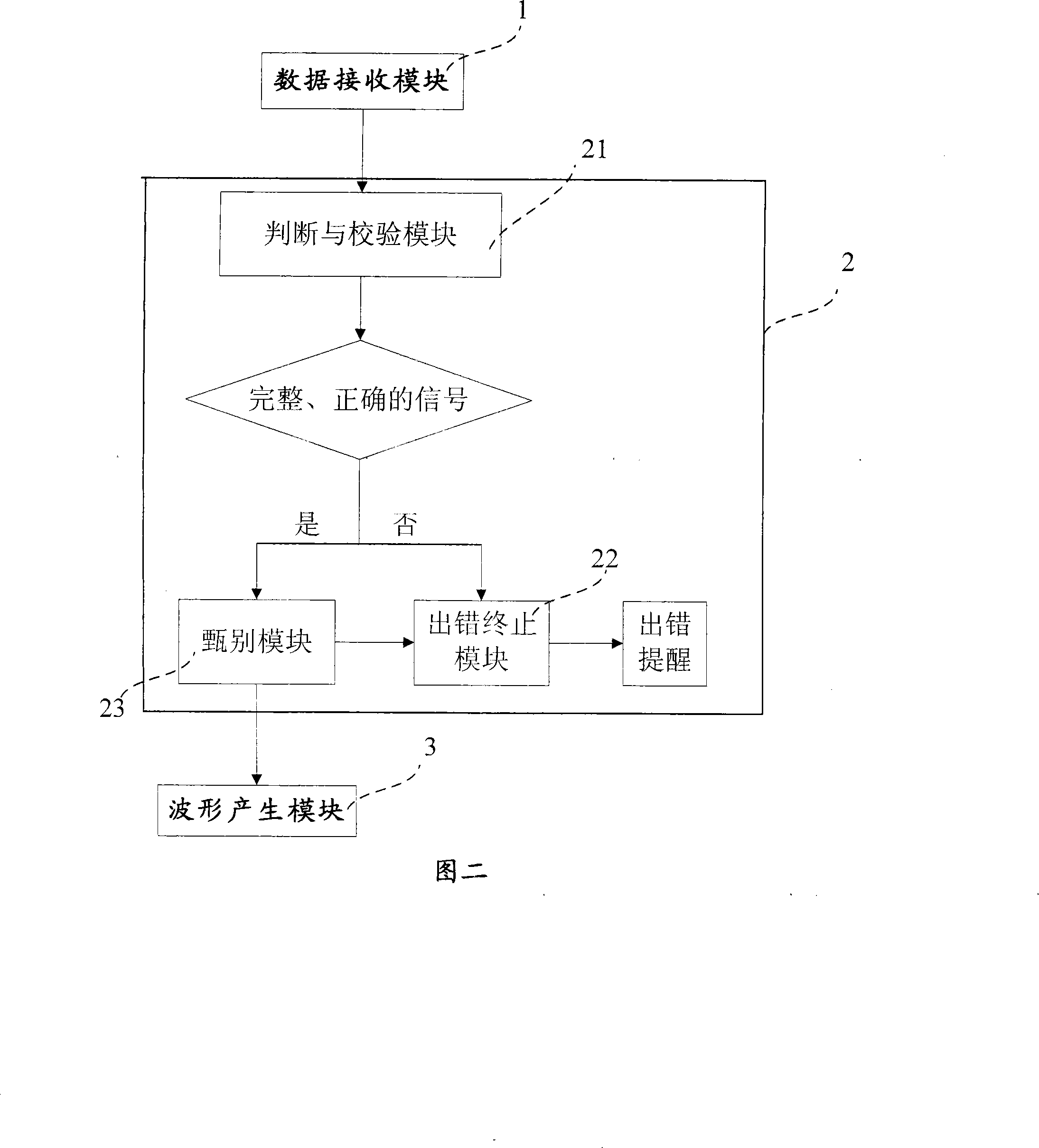

[0029] A signal processing module 2, used to perform parameter separation processing on at least one group of parameter signals including the first group of parameter signals, and output various control parameters, these control parameters include at least reference pulse signal, high-voltage pulse signal, communication signal , grouping width, grouping interval, pulse width Ton, pulse-to-pulse width Toff, single pulse discharge energy, peak current intensity, cycle, front-order wave control parameters, post-order wave control parameters, current control parameters, speed control parameters, comb parameters ;

[0030] A waveform generating module 3, configured to receive various control parameters from the signal processing module 2, and output at least two pulse signals according to the control parameters;

[0031] A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com