Gas flow rate calibrating method

A technology of gas flow and flow, which is applied in liquid/fluid solid measurement, instrument calibration, test/calibration devices, etc., and can solve problems such as increasing costs and prolonging calibration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

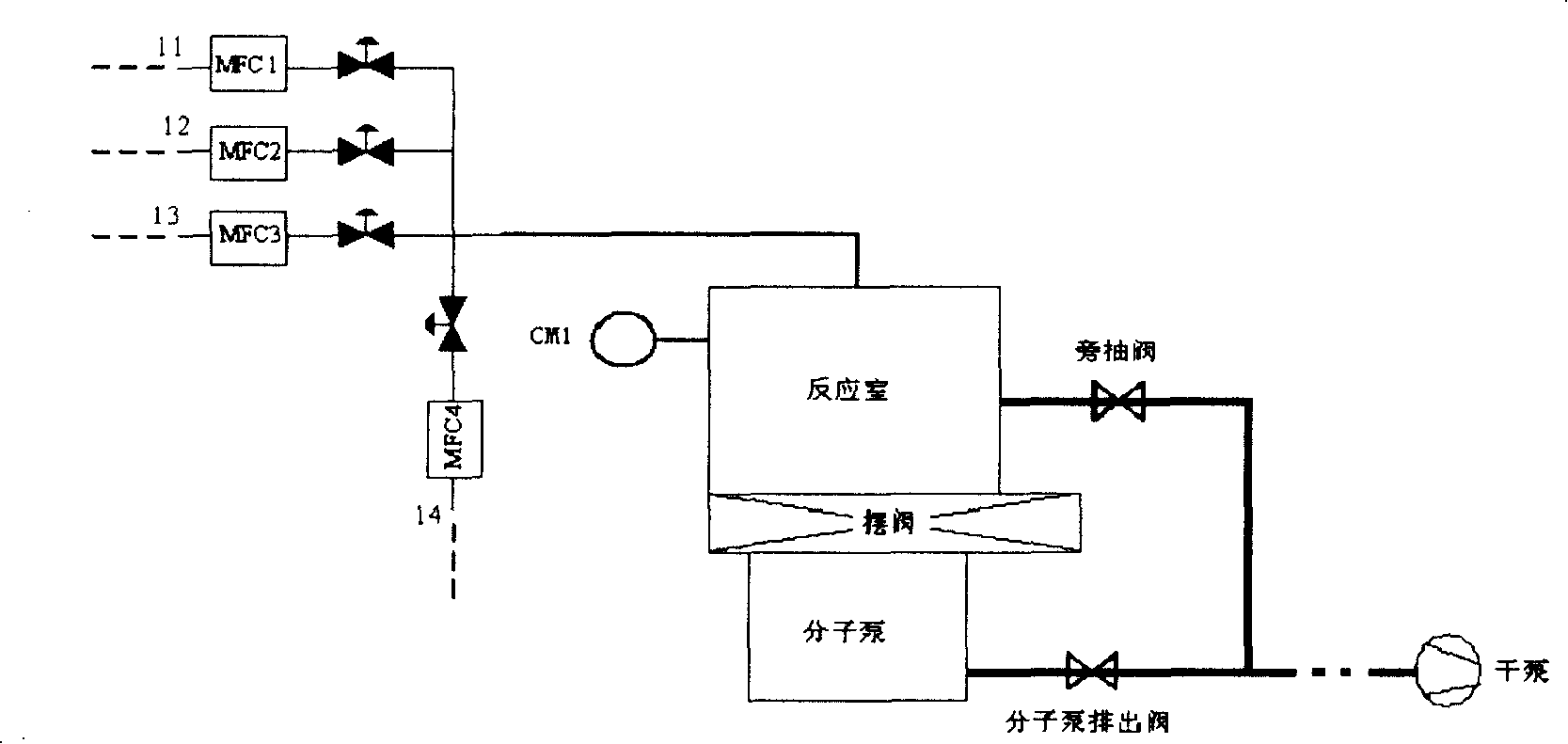

Method used

Image

Examples

Embodiment approach

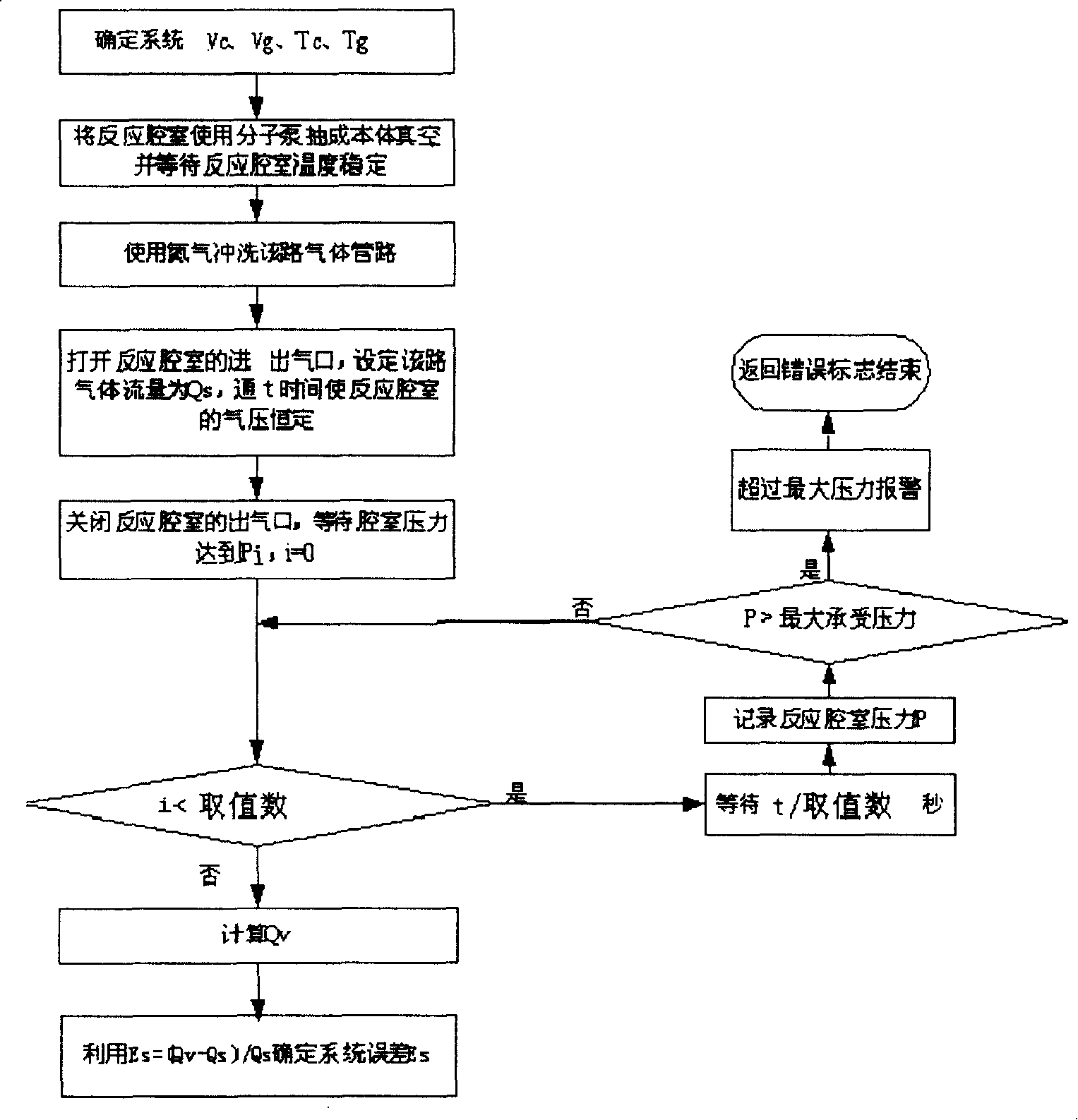

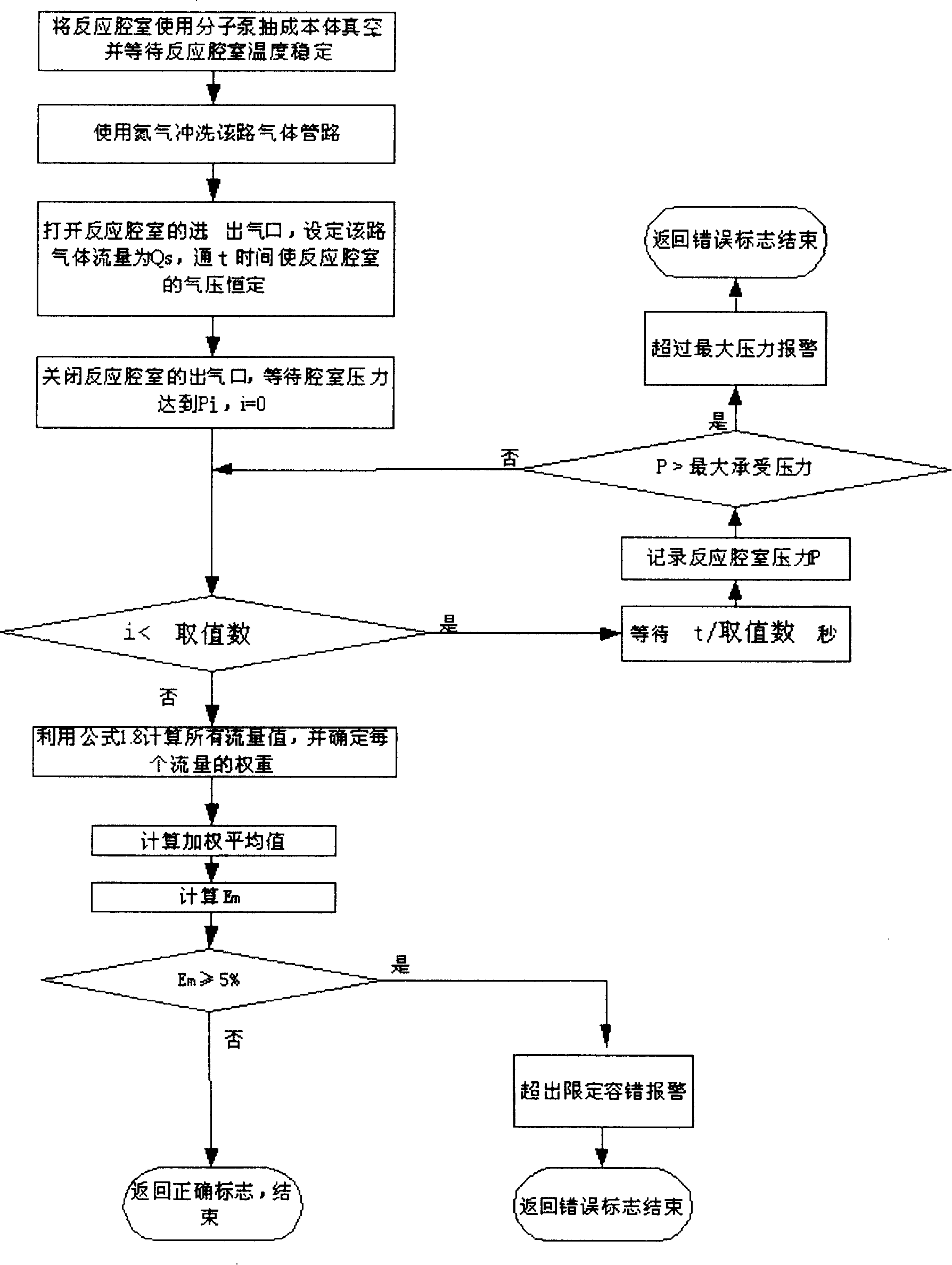

[0074] Its preferred embodiment comprises the following steps:

[0075] Step 11, when the MFC is newly installed in the gas supply system, first measure the inherent error Es of the system, the flow error Em=0 of the newly installed MFC, the method of measurement is:

[0076] Supply gas to the reaction chamber through the gas supply pipeline of the newly installed MFC, measure the change of gas parameters in the gas supply pipeline and the reaction chamber, and calculate the flow rate Qv of the gas through the ideal gas state equation PV=nRT;

[0077] Compare Qv with the set flow value Qs of MFC to get the error of MFC E = Q v - Q s Q s ;

[0078] The inherent error Es=E of the system can be obtained from the formula E=Es+Em;

[0079] Step 12. After the MFC has be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com