Dummy bar head suitable for hard aluminum alloy flat bloom semi-continuous casting

A hard aluminum alloy and dummy head technology, which is applied in the field of aluminum alloy semi-continuous casting, can solve problems such as hard aluminum alloy flat ingots are easy to crack, achieve long working life, eliminate cracking, and ensure casting safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

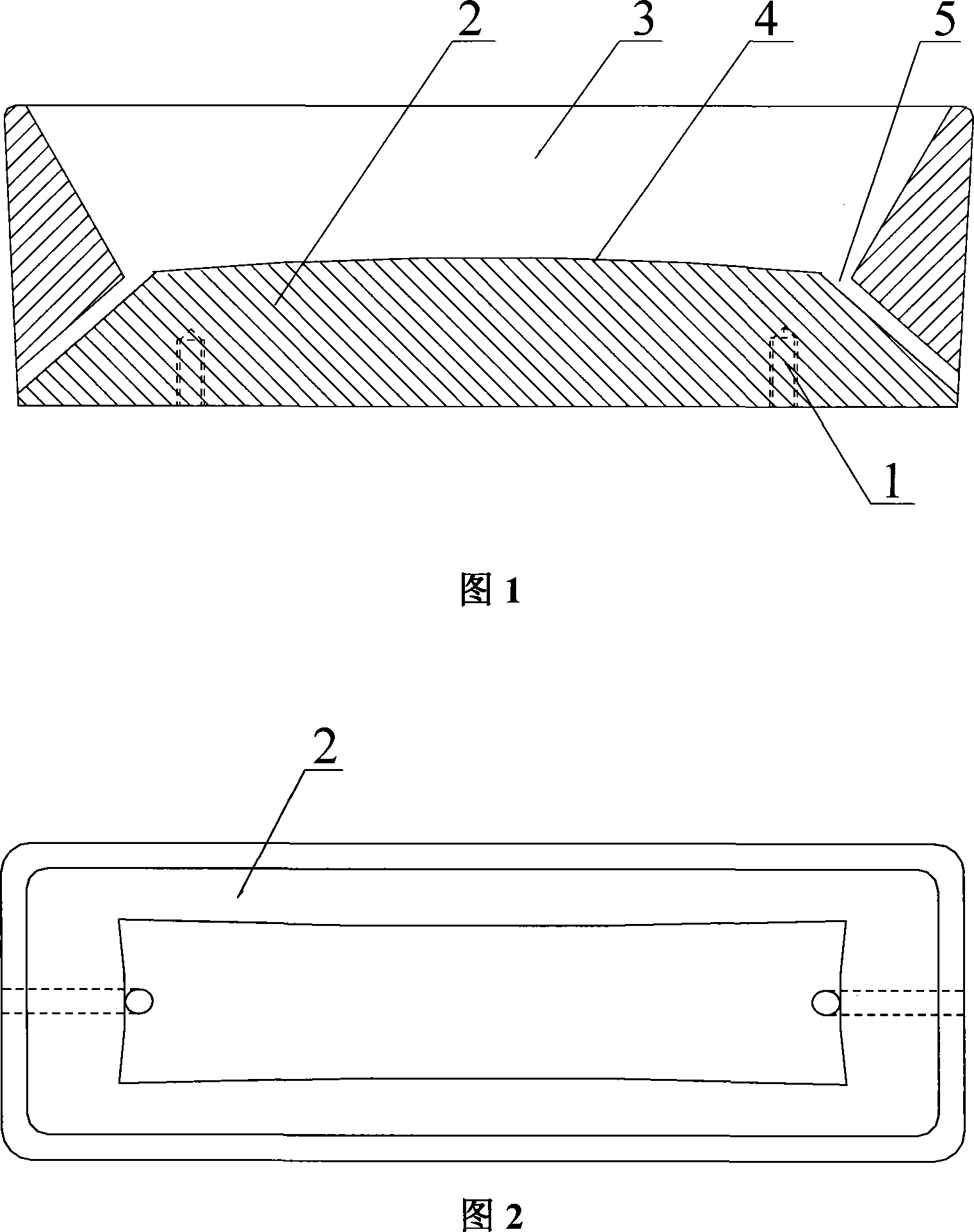

[0017] As shown in Figure 1 and Figure 2, a dummy head suitable for semi-continuous casting of hard aluminum alloy flat ingots, including dummy head body 2 and internal cavity 3, the material of the dummy head is small in thermal deformation coefficient and has low thermal conductivity Relatively poor flat steel, the bottom surface 4 of the internal cavity is an upwardly convex hyperboloid, and the ratio between the depth of the internal cavity and the radius of curvature of the hyperboloid bottom surface and the size of the aluminum alloy flat ingot is (0.8 to 1.5 ): (16~20): (4~7); and the four side walls of the internal cavity are tapered, and the angle between the side wall and the vertical surface is 25°~55°; the bottom of the internal cavity is provided with Drain holes 5 are arranged; the outer wall of the dummy head is a negative cone with a cone angle of 3°. The bottom of the dummy head has a threaded hole 1.

[0018] The inner cavity 3 of the dummy head is relativel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com