Infrared bo-mei board and preparation method thereof

An infrared glass-magnesium board and glass-magnesium board technology is applied in sustainable waste treatment, solid waste management, climate sustainability, etc. Intensity, high infrared emissivity, effect of significant health care effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

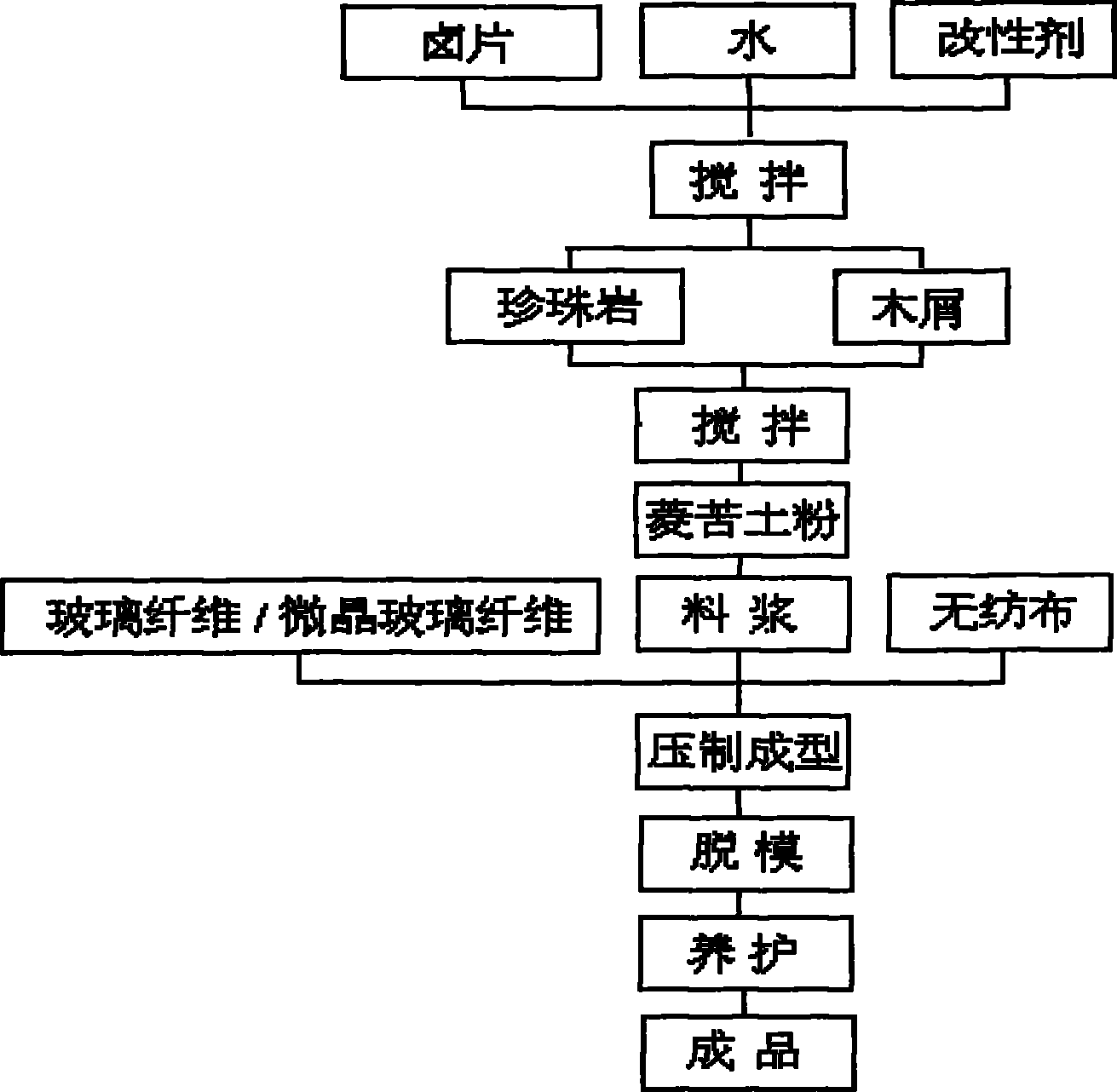

Method used

Image

Examples

Embodiment 1

[0035] First prepare the modifier, mix sodium phosphate, sodium tripolyphosphate, and hot water with a mass ratio of 1:1:10 to prepare 50 kg of the modifier, and set it aside for use. Then weigh 200 kilograms of magnesite powder, 60 kilograms of wood chips, 30 kilograms of perlite, 200 kilograms of bittern, 16 kilograms of modifiers, and 1 kilogram of polysiloxane. Mix 200 kg of brine with 16 kg of modifier, add 0.6 kg of polysiloxane, and stir evenly. Add 2 / 3 (i.e. 134 kg) of the magnesite powder required for each batch into the mixer, add the mixed solution of brine and modifier under stirring, stir for about 10 minutes, then add the remaining 66 kg of magnesite powder , stirred for 3 minutes, and the stirring speed was 60-120 rpm. Then add 72 kilograms of the mixture of sawdust and water, 36 kilograms of the mixture of perlite and water, and 0.4 kilogram of the remaining defoamer, and stir for 6 minutes.

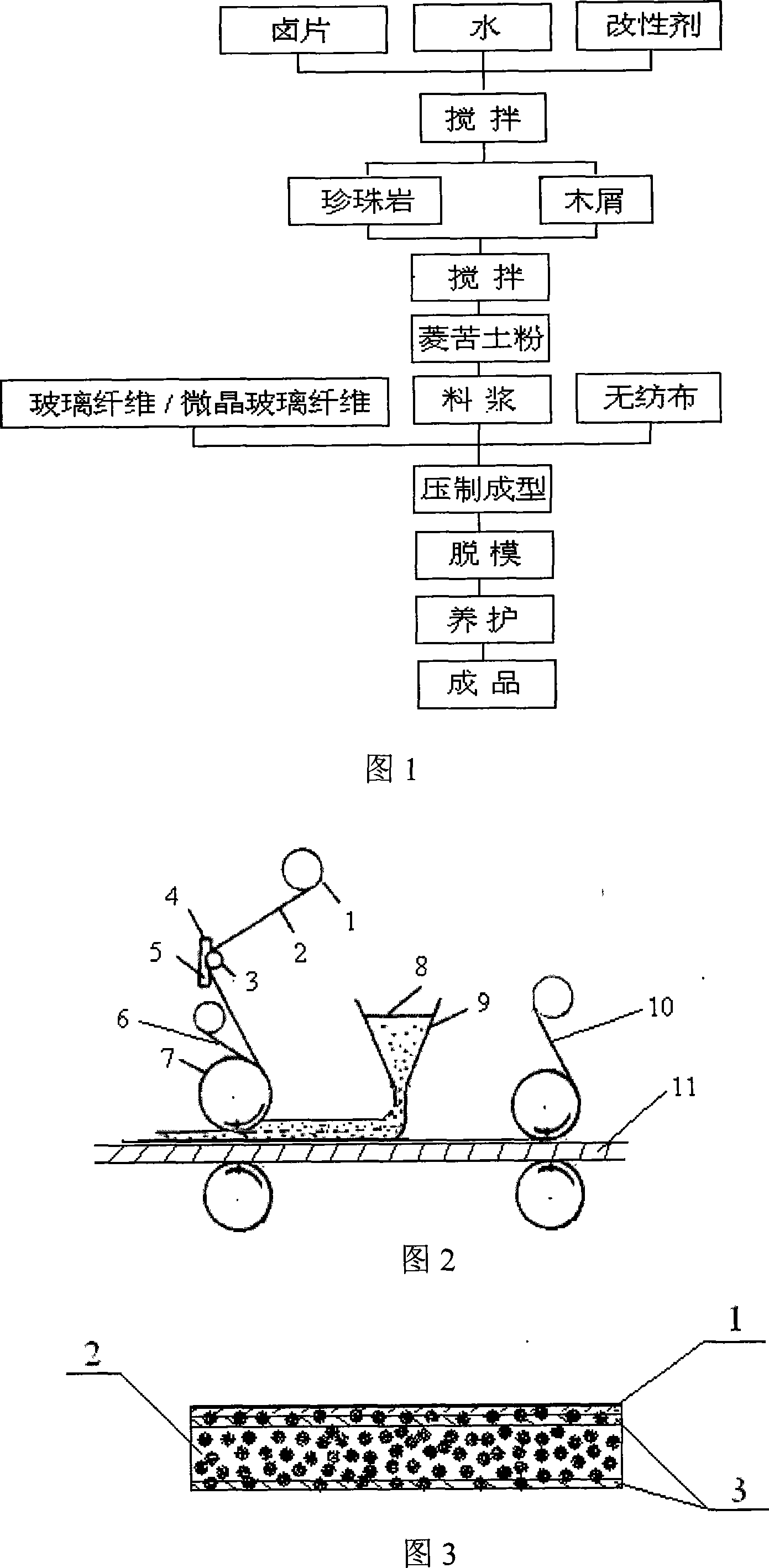

[0036]Brush an appropriate amount of oil release agent on the temp...

Embodiment 2

[0038] First prepare modifier, aluminum sulfate, urea-formaldehyde resin, naphthalenesulfonic acid NNO, sodium phosphate, triethanolamine, hot water are mixed according to the mass ratio of 1: 1: 1: 1: 9: 10 to prepare 50 kg of modifier ,stand-by. Then weigh 200 kilograms of magnesite powder, 60 kilograms of wood chips, 30 kilograms of perlite, 200 kilograms of bittern, 16 kilograms of modifiers, and 1.5 kilograms of polysiloxanes. Mix 200 kg of brine with 16 kg of modifier, add 0.7 kg of polysiloxane, and stir evenly. Add 2 / 3 (i.e. 134 kg) of magnesite powder required for each batch into the mixer, add the mixed solution of brine and modifier under stirring, stir for about 10 minutes, then add the remaining 66 kg of magnesite powder , stirred for 3 minutes, and the stirring speed was 60-120 rpm. Then add 73 kilograms of the mixture of sawdust and water, 38 kilograms of the mixture of perlite and water, and 0.8 kilogram of the remaining defoamer, and stir for 6 minutes.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com