Double microscopic digital speckle strain measurement method

A technology of strain measurement and digital speckle, applied in the direction of measuring devices, instruments, and optical devices, can solve the problems of inability to carry out safety inspections of bridges in service, waste of financial resources, manpower, material resources, and long inspection cycles, etc., and achieve economic benefits Substantial, low resource consumption, and short detection cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

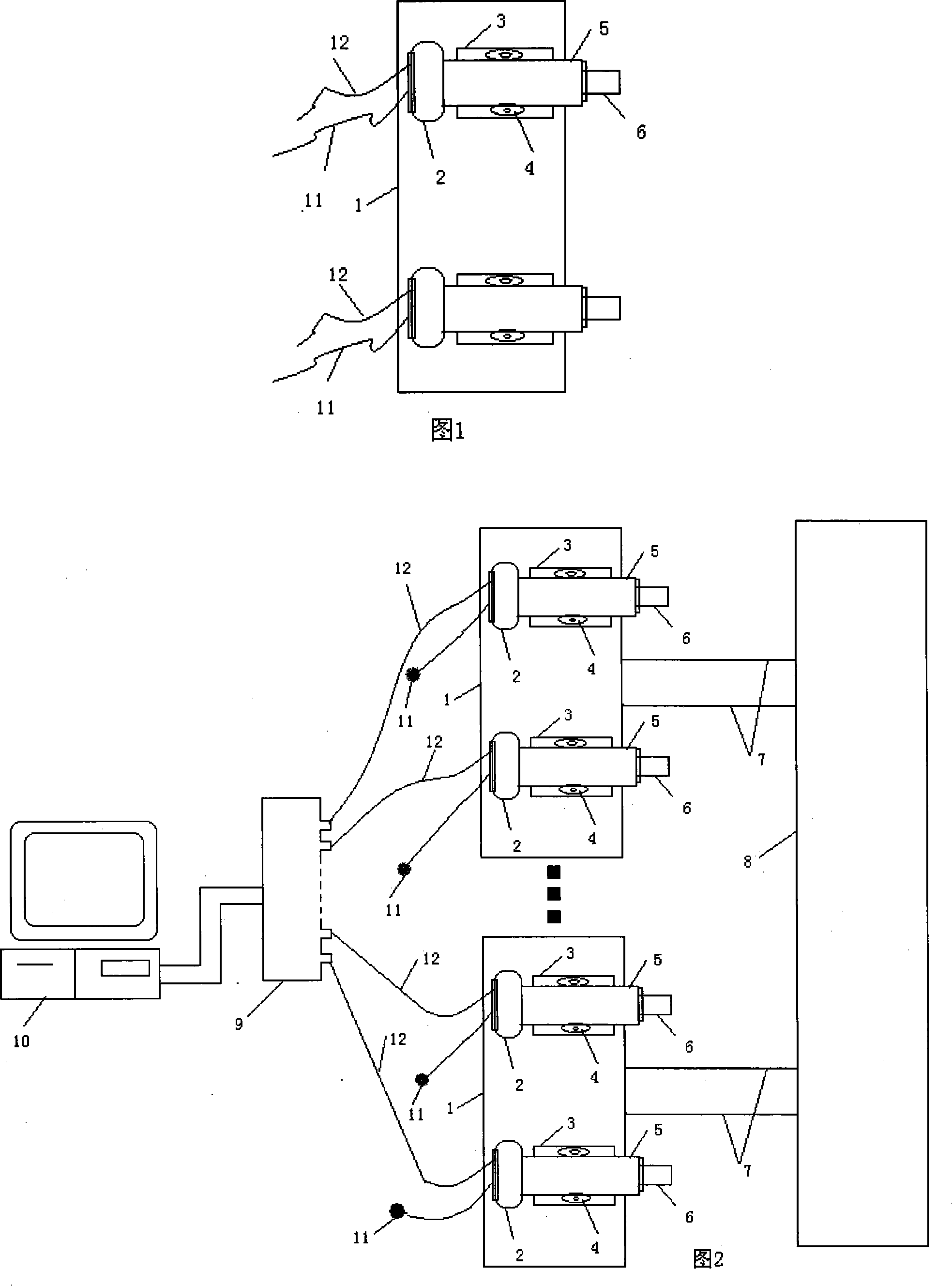

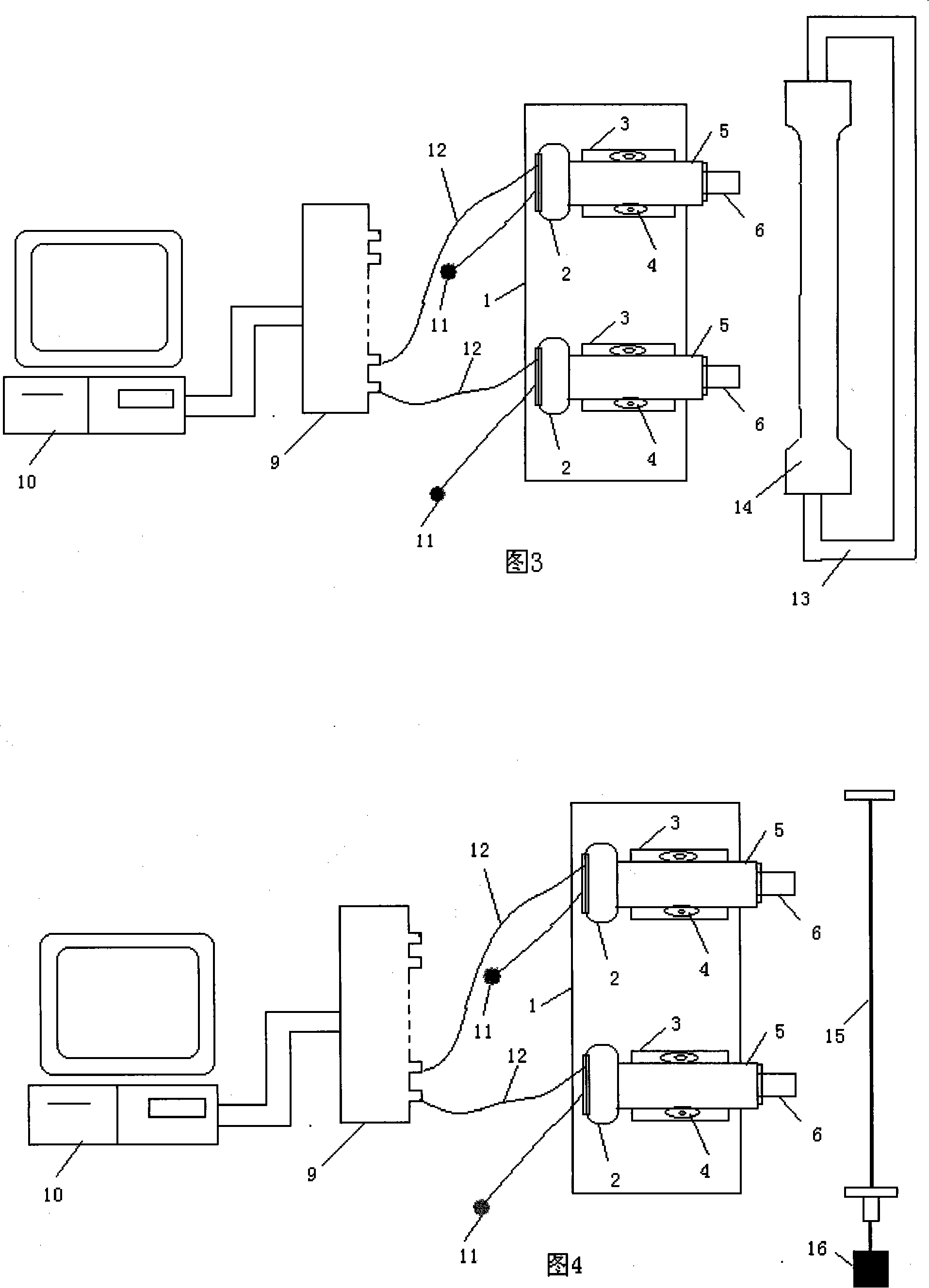

[0021] Implementation 1: Measurement of micro-strain of large bridge components. As shown in accompanying drawing 2, the CCD 2 that is a group of band microscope lens 6 is installed on the fixed platform 1, according to the needs of measurement, multiple groups of such double microscopic CCD digital detection devices are set, and then the CCD 2 The fixed platform 1 and the measuring bridge deck 8 are connected into a unified body with the bridge deck fixing bolts 7 . Spray paint on the measurement bridge deck 8 to form a speckle field with better correlation performance, adjust the focus handwheel 4 of the lens barrel 5 to achieve the best image effect, and use the dual CCD 2 to simultaneously collect the distance between two points of the measured object The speckle images within the gauge distance before and after loading are transmitted to the PC 10 through the multi-channel image acquisition card 9, and the mechanical parameters of the measured object can be obtained throu...

Embodiment 2

[0022] Implementation 2: Measurement of the micro-strain of the plexiglass specimen. As shown in Figure 3, the plexiglass is processed into a standard test piece, and the plexiglass test piece 14 is sprayed with paint to make spots to form a speckle field with better correlation performance; the other end of the test piece is pasted with a strain gauge. The test piece and the double-microscopic digital speckle strain device are placed on the loading frame 13 of the mechanical experiment for tensile experiments. A comparative measurement is carried out, and the measurement results are completely converging.

Embodiment 3

[0023] Implementation 3: Measurement of the micro-strain of the plexiglass specimen. As shown in accompanying drawing 4, same as the above-mentioned example method, the dual microscopic digital speckle strain measurement method and the optical lever measurement method of the present invention are used to simultaneously measure the elastic modulus of the metal wire under the load of each increased load of 0.5kg weight, so The relative error of measuring the elastic modulus of the metal wire is less than 3%. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com