Reliability design method for wireless data acquisition of timber drying process

A wireless data and wood drying technology, applied in the direction of data exchange, signal transmission system, instruments, etc. through path configuration, can solve the problems of inconvenient system redeployment or update, high energy consumption, high installation and maintenance costs, and reduce Installation and maintenance costs and energy consumption, energy saving costs, and loss prevention effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

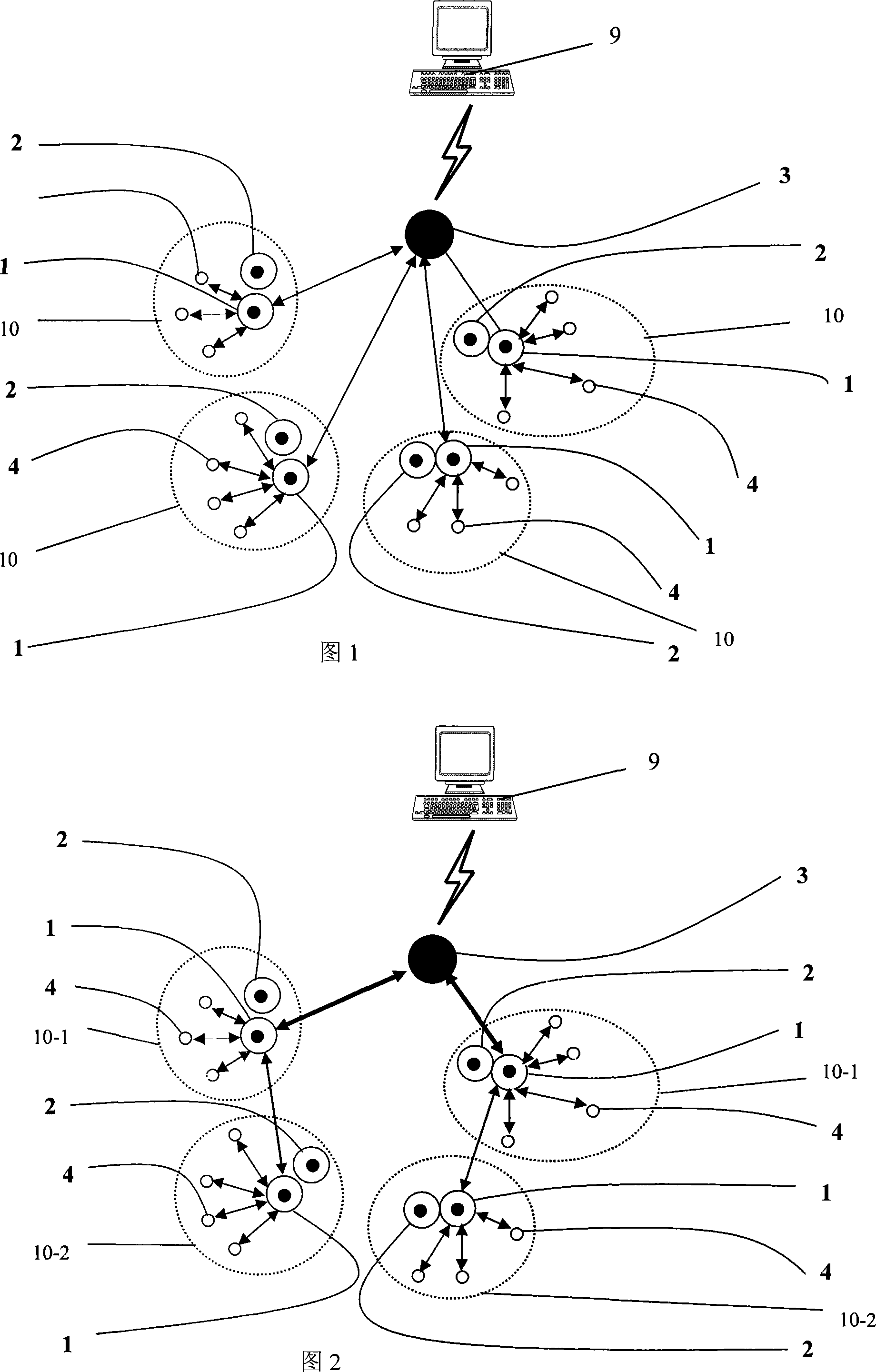

[0046]In Fig. 1, the topological structure of a wireless sensor network data acquisition system in single-layer mode is described. For the monitoring of a single drying kiln, this mode can generally be used. Each cluster head in the whole kiln communicates with the control center through the wireless gateway. The figure shows that all nodes are divided into four clusters 10 (indicated by circles). The number of clusters 10 can be determined as required.

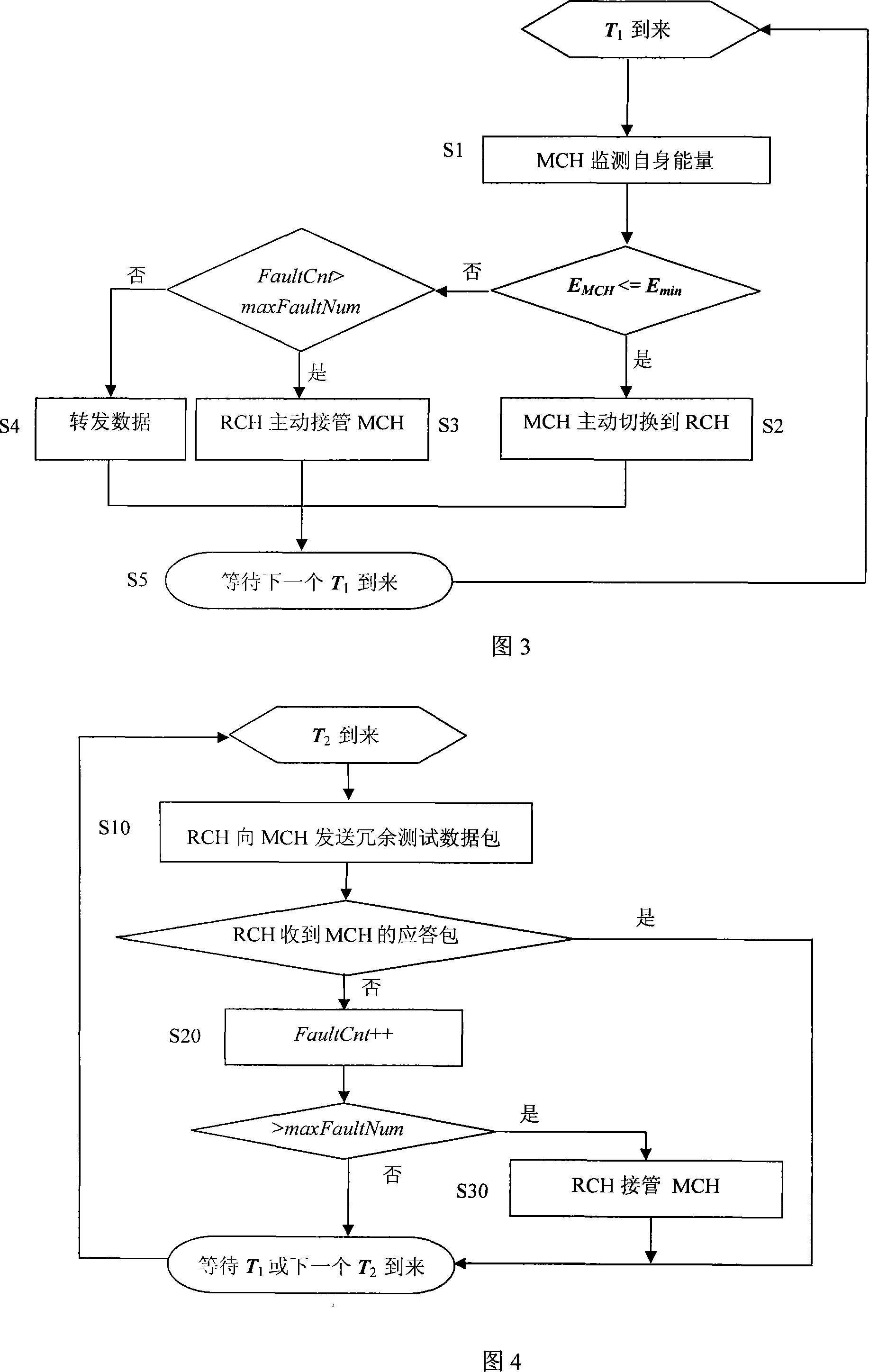

[0047] In Fig. 2, a network topology structure of a two-layer mode data acquisition system is described. This mode is suitable for the monitoring of a single kiln with a large volume and the monitoring of multiple drying kilns. When the volume is large, some cluster heads may be far away from the wireless gateway, and the use of two-layer or multi-layer mode will reduce energy consumption and improve network scalability. The figure shows that all nodes are also divided into four clusters 10-1 and 10-2 (both represented by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com