Steel roller type bundling gathering binder

A baler and steel roller technology, applied in packaging, agricultural machinery and implements, applications, etc., can solve the problems of unresolved overall structure, reduced baling quality, unsmooth feeding, etc., to achieve good baling quality and operation. The effect of less failure and smooth feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

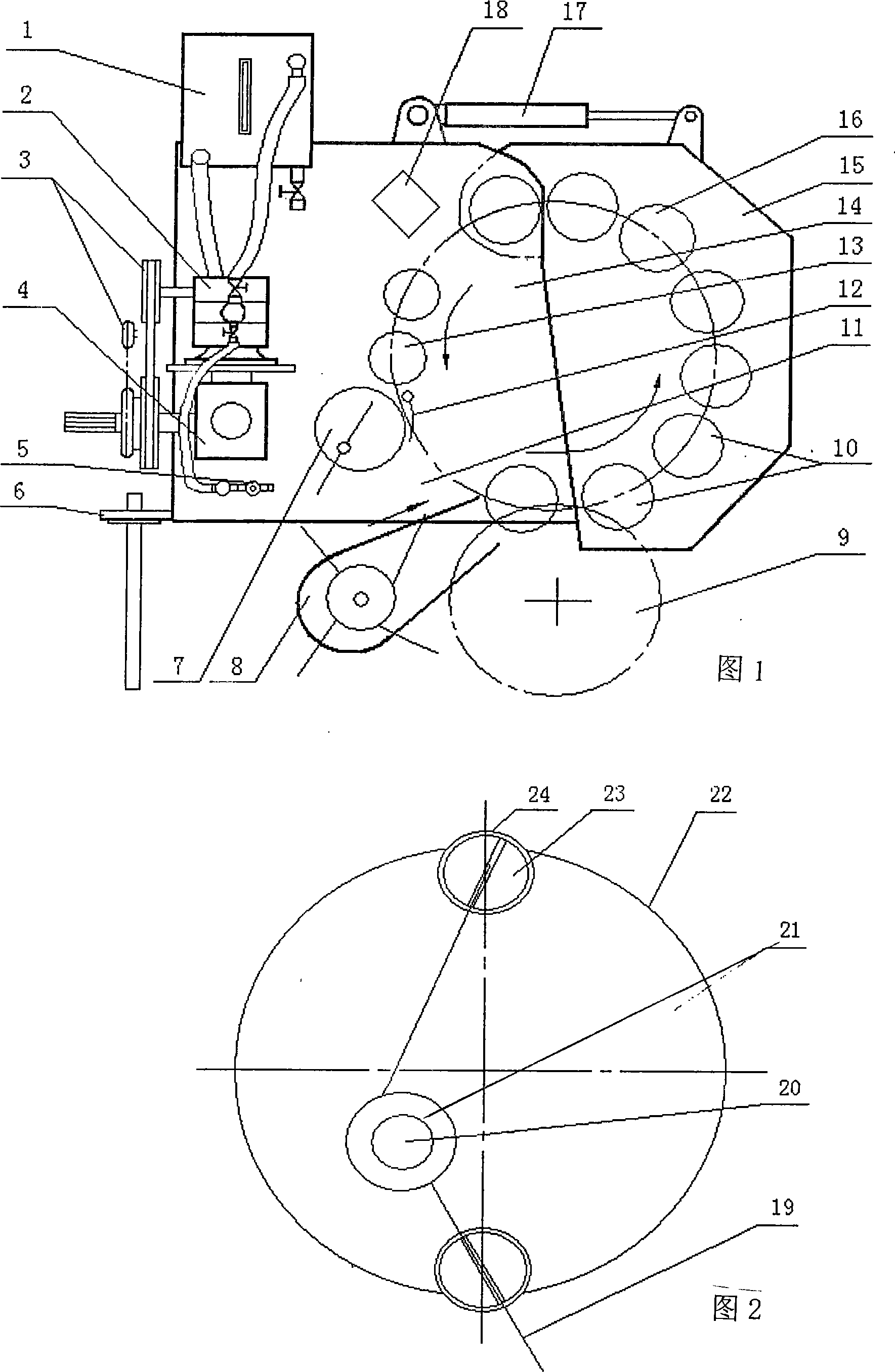

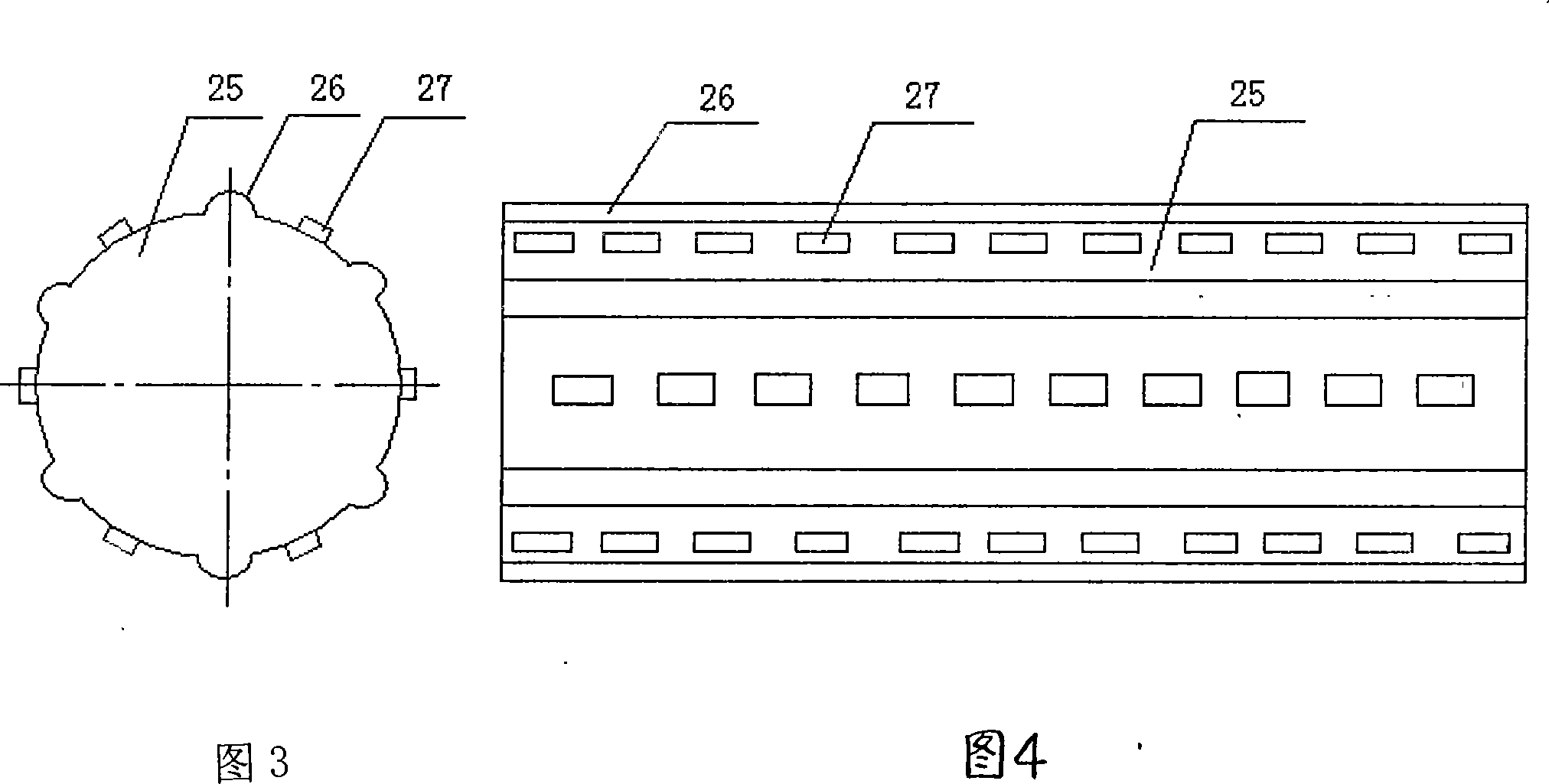

[0012] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. The steel roller round baler picking and binding machine includes a frame assembly 6 and a liquid additive storage tank 1 mounted on the frame assembly 6, a liquid spray pump 2, a transmission system 3, a main drive bevel gear box 4, and a nozzle 5 , elastic tooth type picker 8, walking wheel 9, round bale baling front chamber 14, round bale baling rear chamber 15, coiled grass steel roller 16, hydraulic bale releasing mechanism 17 and baling rope feeding mechanism 18, in the round bale The outer side of the baling chamber straw entrance 11 on the lower part of the baling front chamber 14, and the upper part of the spring-toothed pick-up 8 are equipped with a retractable tooth-type grass pulling roller 7, and the grass pulling roller guard plate 12 is equipped on the telescopic tooth-type grass pulling The side part of the drum 7 is located on the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com