Rotary hydraulic machinery double function expansion type tail pipe hanger

A liner hanger and hydraulic machinery technology, applied in wellbore/well components, earthwork drilling, sealing/packing, etc., can solve problems such as complex structure, small diameter, unreliable seat hanger, etc., and achieve structural Simple, reduce air bubbles, improve the effect of cementing success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

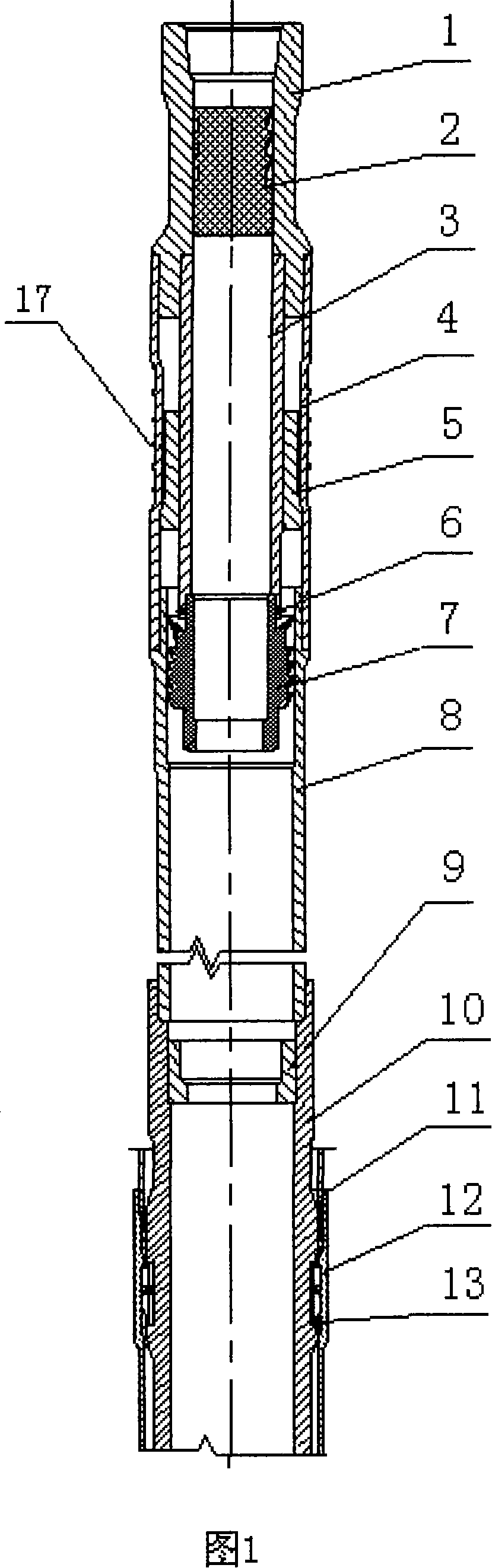

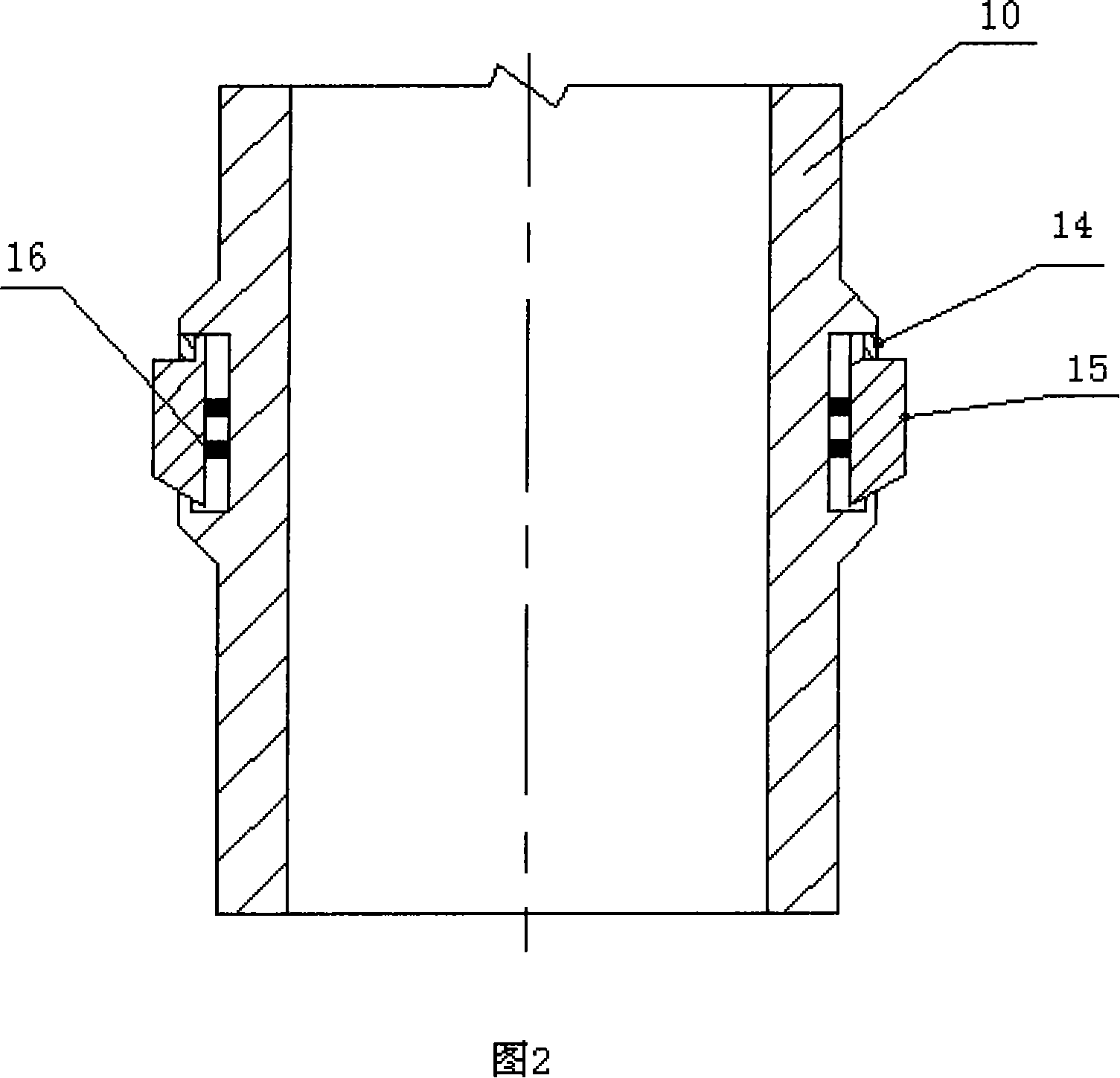

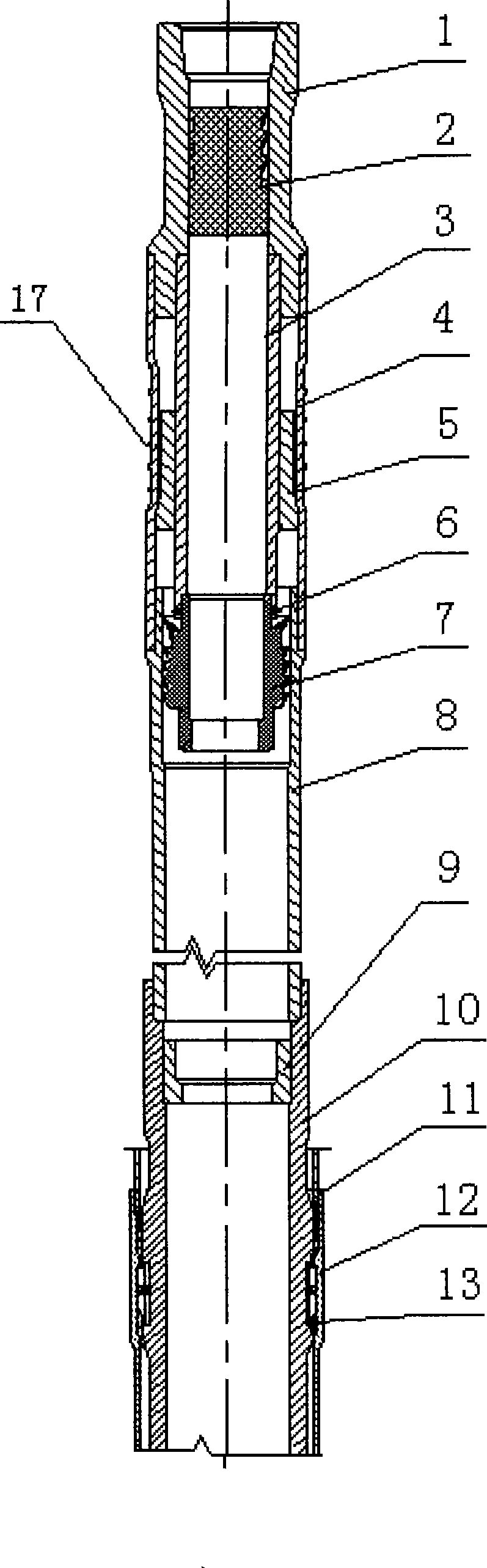

[0017] Example 1: See attached figure 1 . Take a 95 / 8"-7" mechanical hydraulic double-acting expansion tailpipe hanger as an example for specific description.

[0018] The maximum outer diameter of the feeding connector 1 is 210 mm. The central tube 3 has a length of 1355 mm, an inner diameter of 82 mm, and an outer diameter of 120 mm. The length of the expansion tube 4 is 1400 mm. There are two annular protrusions 17 on the outside of the expansion tube 4. The annular protrusion 17 has a trapezoidal cross-section and a thickness of 5 mm. The diameter of the outer edge of the annular protrusion 17 is the same as the maximum diameter of the expansion tube 4.

[0019] There are threads on the upper part of the feeding joint 1, which can connect the mechanical hydraulic double-acting expansion liner hanger to the lower end of the feeding pipe string, and send the mechanical hydraulic double-acting expansion liner hanger into the downhole suspension position. The outer wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com