Purification device for decreasing particulate matter and nitrogen oxides in diesel engine

A technology of nitrogen oxides and purification devices, which is applied to the electronic control of noise reduction devices, exhaust devices, and exhaust treatment devices, and can solve problems such as complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

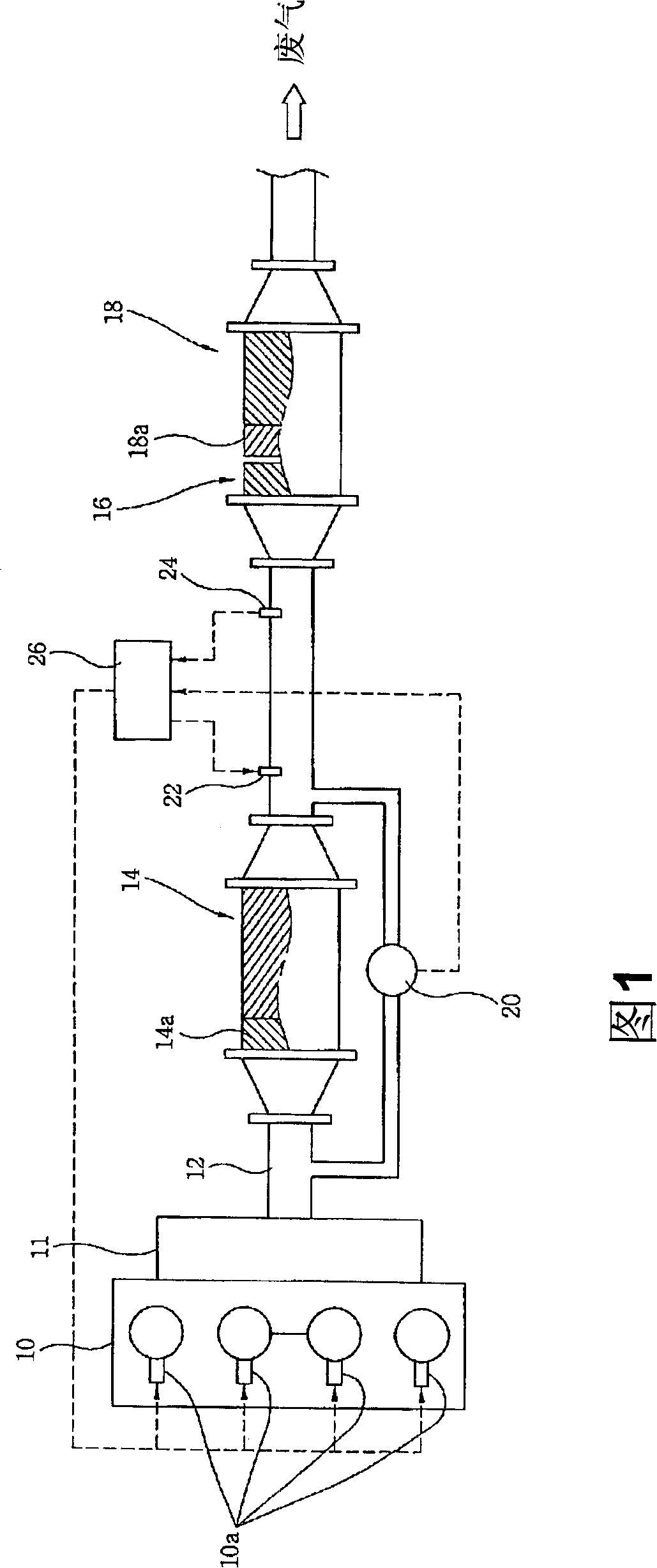

[0038] Also, in the present invention, based on the exhaust path, the diesel fuel decomposition catalyst (DFC) 16 is located at the upstream end of the nitrogen oxide adsorption catalyst (de-NOx catalyst) 18, and the catalytic diesel particulate filter (CDPF) 14 is located at the nitrogen oxidation The upstream end of the substance adsorption catalyst (de-NOx catalyst) 18. According to the first embodiment of the present invention, a catalyzed diesel particulate filter (CDPF) 14 is disposed in front of a diesel fuel decomposition catalyst (DFC) 16 .

[0039] In this case, a diesel fuel decomposition catalyst (DFC) 16 and a nitrogen oxide storage catalyst (de-NOx catalyst) 18 are sequentially arranged in the same housing.

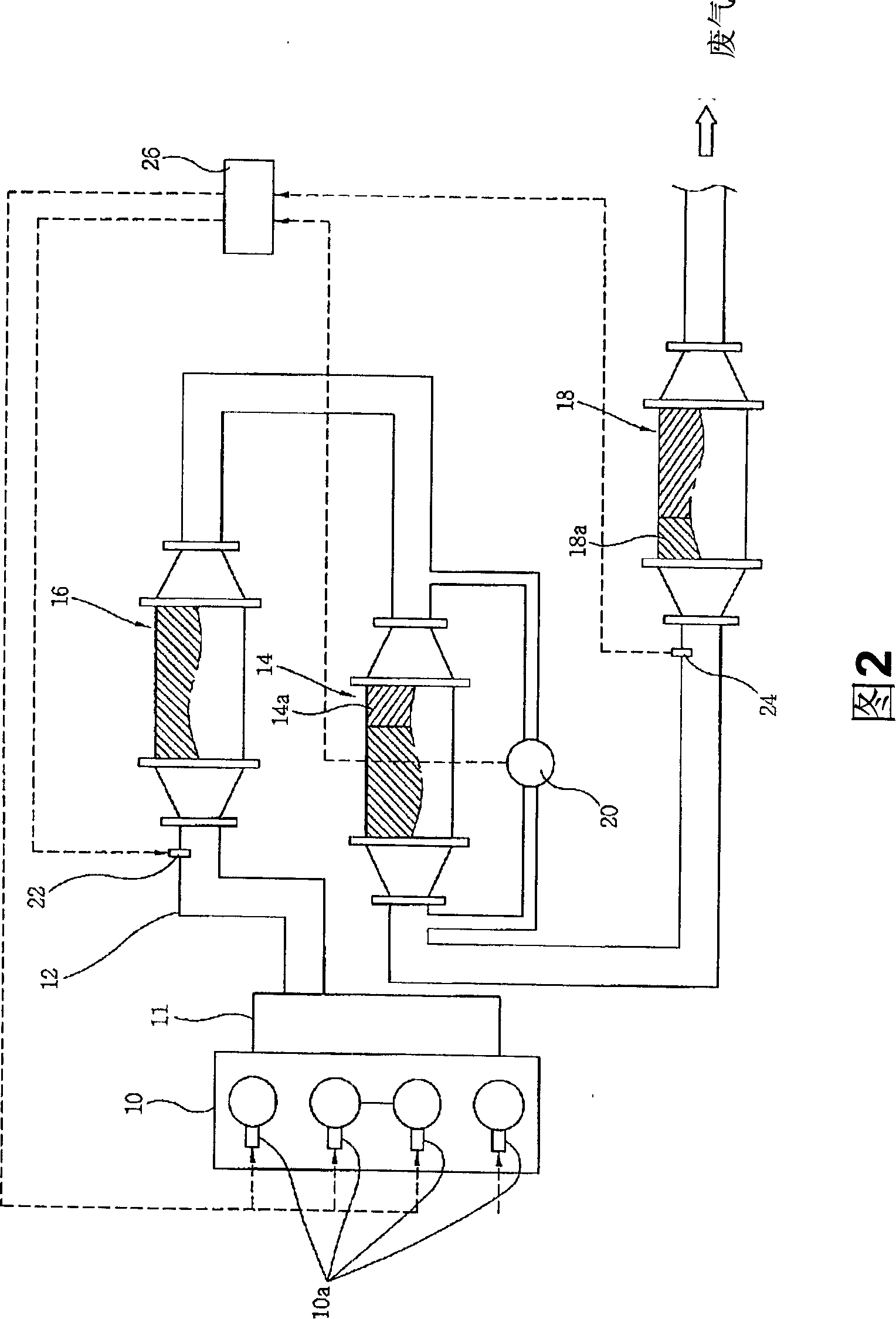

[0040] Referring to Figure 2, a second embodiment of the present invention is shown. According to the second embodiment, a diesel fuel decomposition catalyst (DFC) 16 is provided upstream of a catalyzed diesel particulate filter (CDPF) 14 based on the exhau...

Embodiment approach

[0042] Furthermore, according to the first and second embodiments of the present invention, the post-injection injector 22 is located on the exhaust pipe 12 in front of the diesel fuel decomposition catalyst (DFC) 16, and the nitrogen oxide sensor 24 is located on the nitrogen oxide adsorption catalyst (de- NOx catalyst) 18 on the exhaust pipe 12 ahead.

[0043] In this case, the nitrogen oxide sensor 24 detects the amount of nitrogen oxides (NOx) contained in the exhaust gas flowing through the exhaust pipe 12 in real time, and then outputs it to the control device 26 . The control device 26 estimates the amount of nitrogen oxides (NOx) accumulated in the nitrogen oxide adsorption catalyst (de-NOx catalyst) 18 by inputting signals from the nitrogen oxide sensor 24, and converts the amount of the accumulated nitrogen oxides (NOx) to The amount is compared with the capacity of the nitrogen oxide storage catalyst (de-NOx catalyst) 18, and then the regeneration time of the nitrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com