Submerged entry nozzle for continuous casting

An immersion, nozzle technology, applied in the parts of the connection device, connection, casting equipment, etc., can solve problems such as the accumulation of inclusions and expansion to adjacent areas that cannot be solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Reference will now be made in detail to the preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts.

[0031] In accordance with the concept of the words used in the specification and claims can be defined so that the inventor can best explain the principles of the inventor's invention, the words used in the specification and claims need to be understood in a sense consistent with the invention technical solutions.

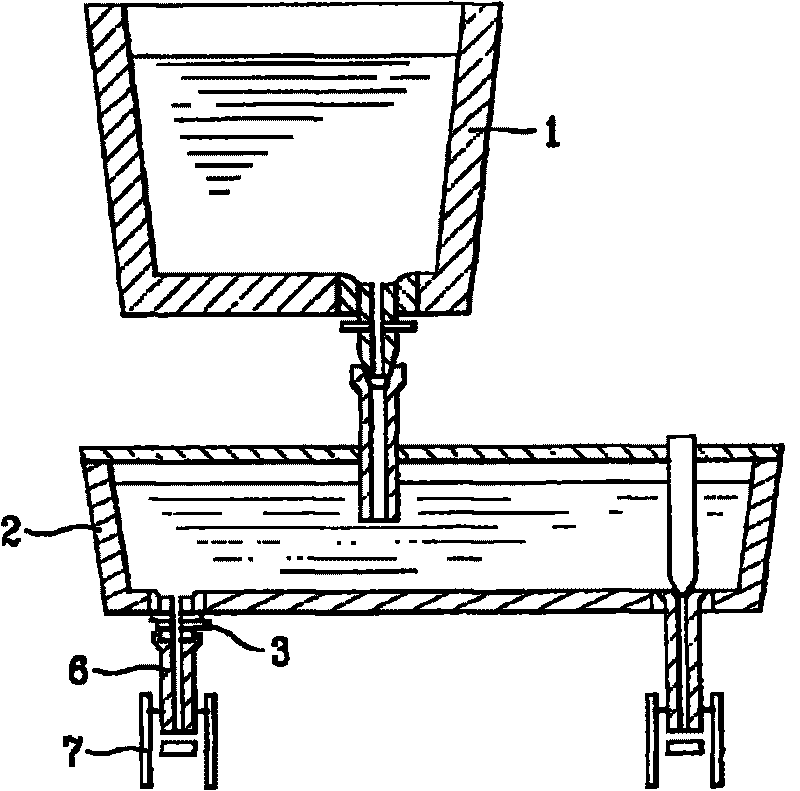

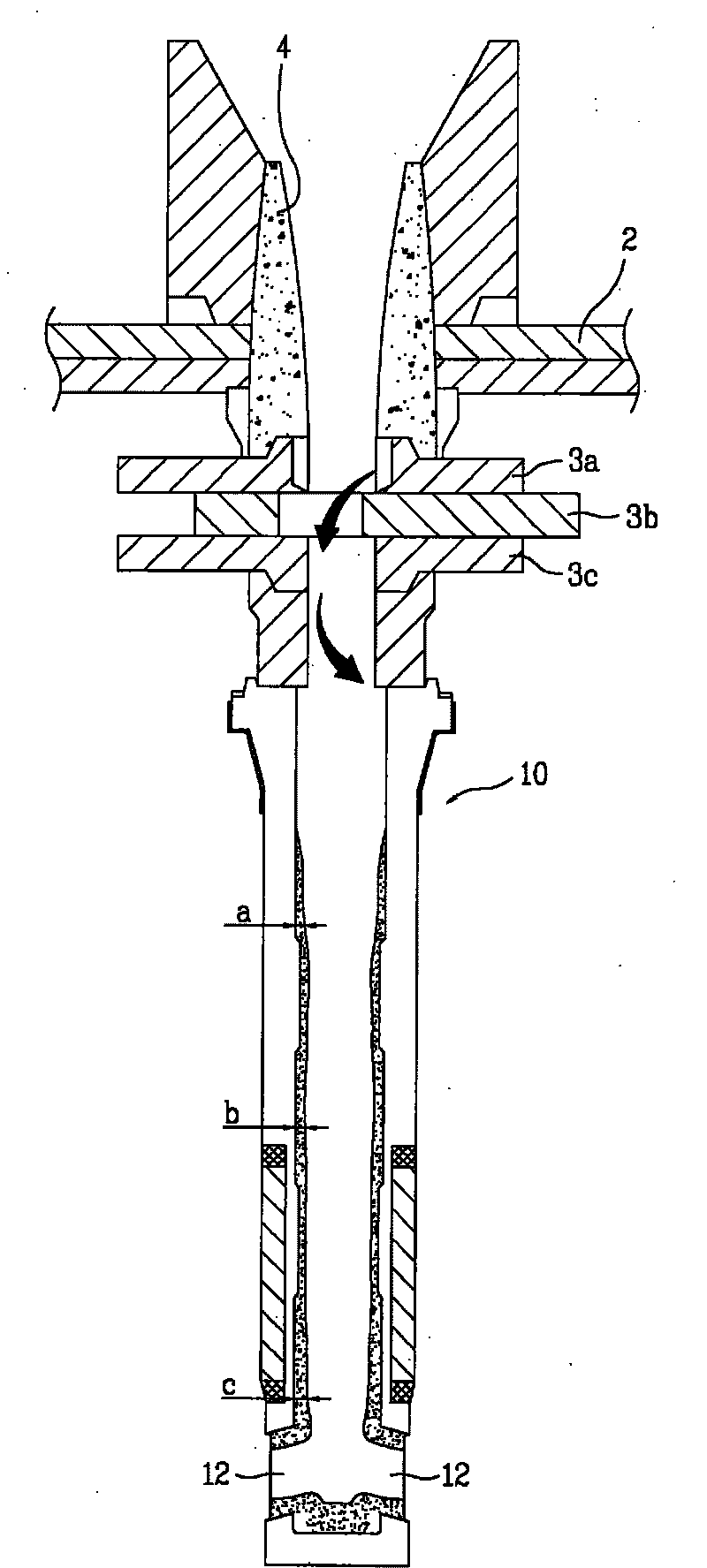

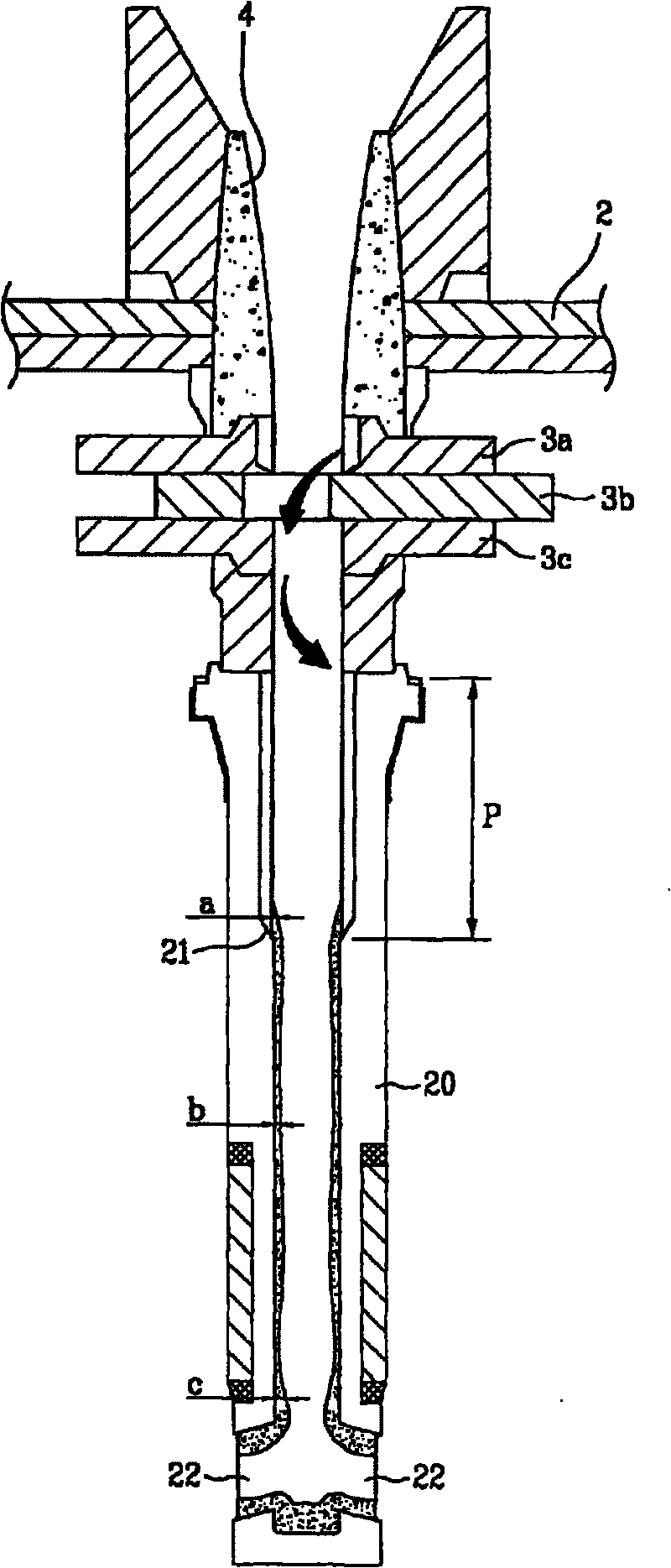

[0032] see Figure 5 with Image 6 , the submerged nozzle 100 for continuous casting is installed in close contact with the underside of the lower plate 3c of the slide plate 3 below the funnel 2, and includes a portion "B" with a patterned cross-section having radial circular grooves so that the steel During the passage of the liquid through the submerged nozzle 100 , the molten steel is pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com