Cheddar cheese manufacturing system and method for manufacturing the cheddar cheese

A cheddar cheese and manufacturing system technology, applied in cheese substitutes, dairy products, applications, etc., can solve the problems of high production cost, labor-intensive, low degree of mechanization, etc., and achieve stable product quality, continuous manufacturing process, and equipment operation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

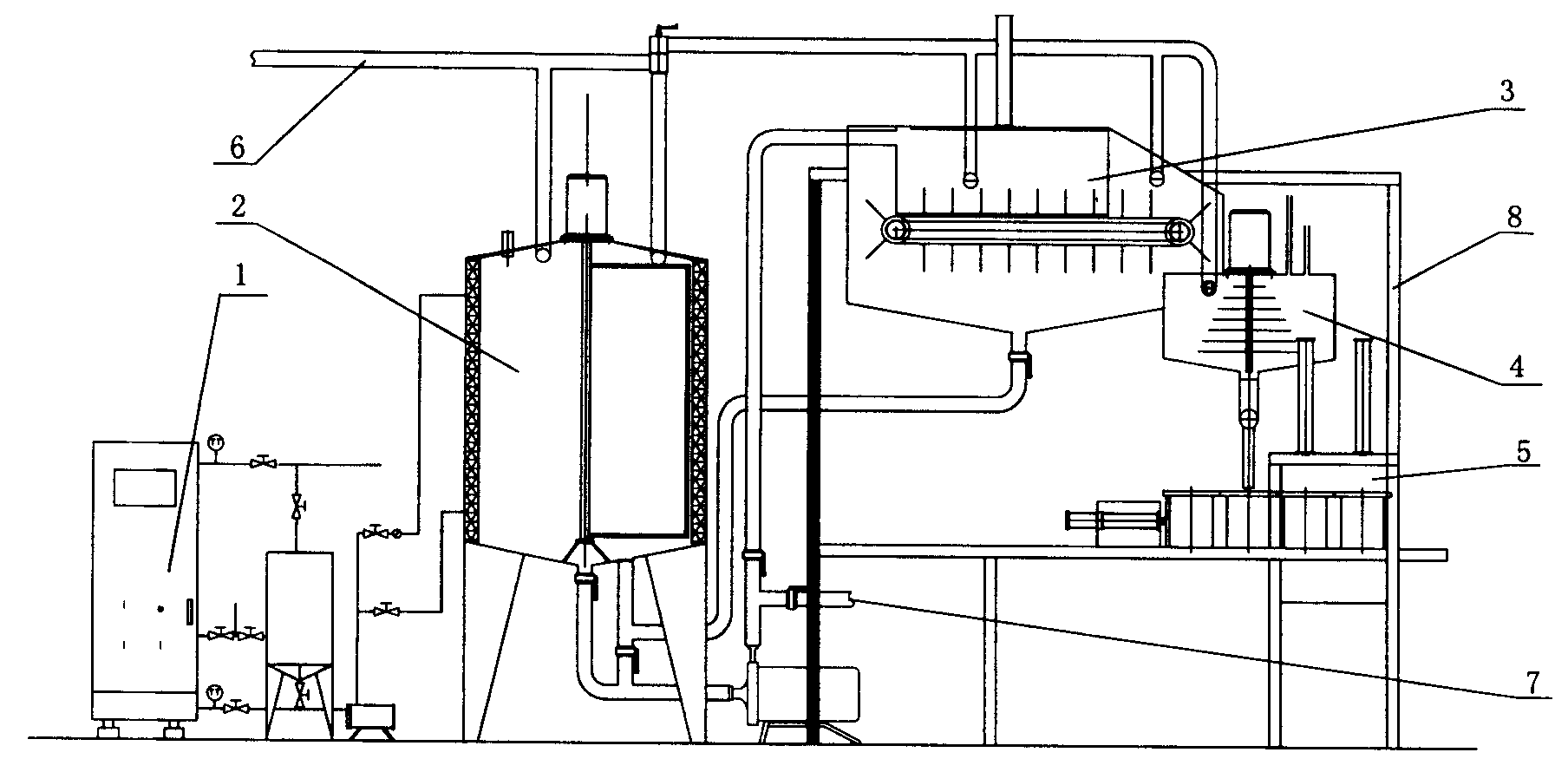

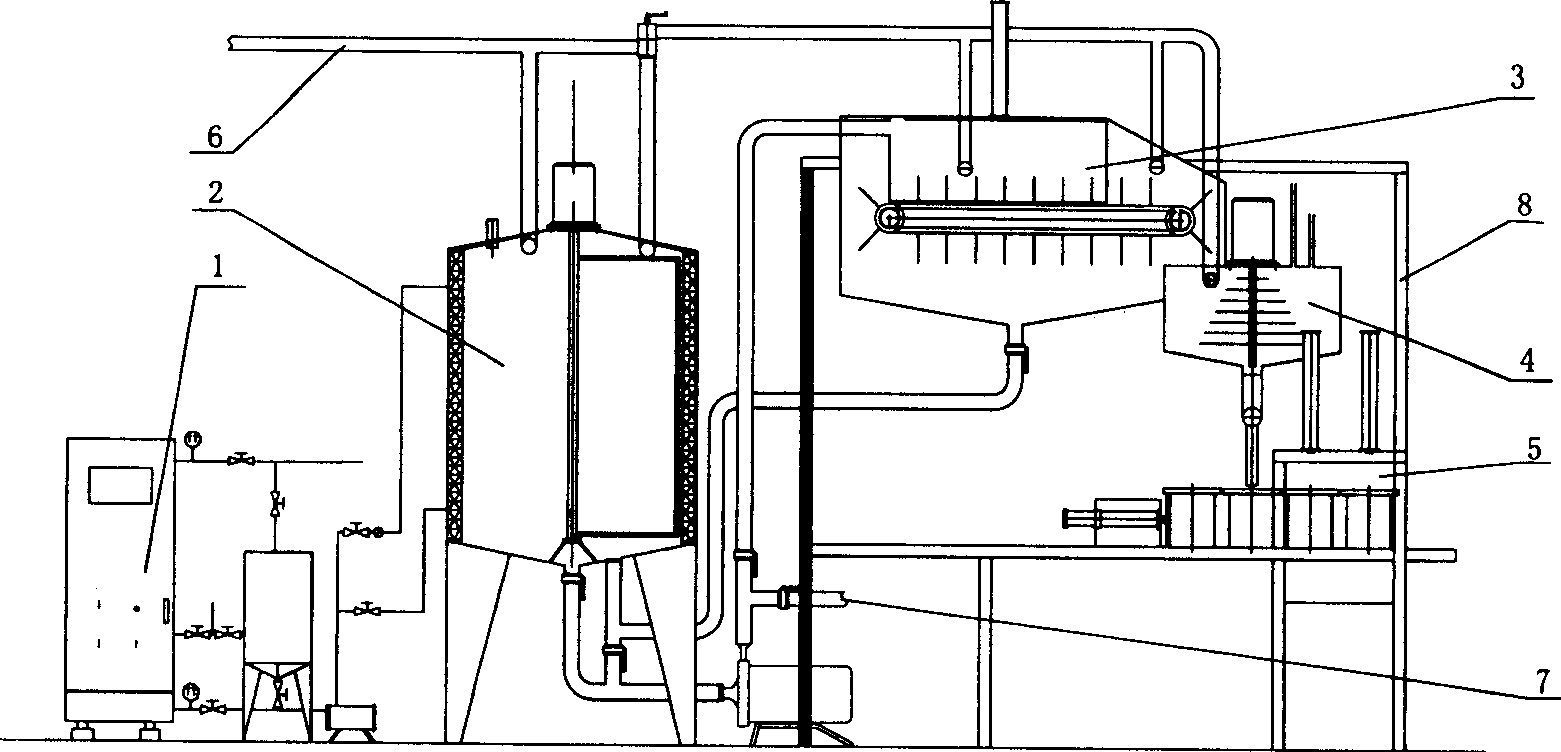

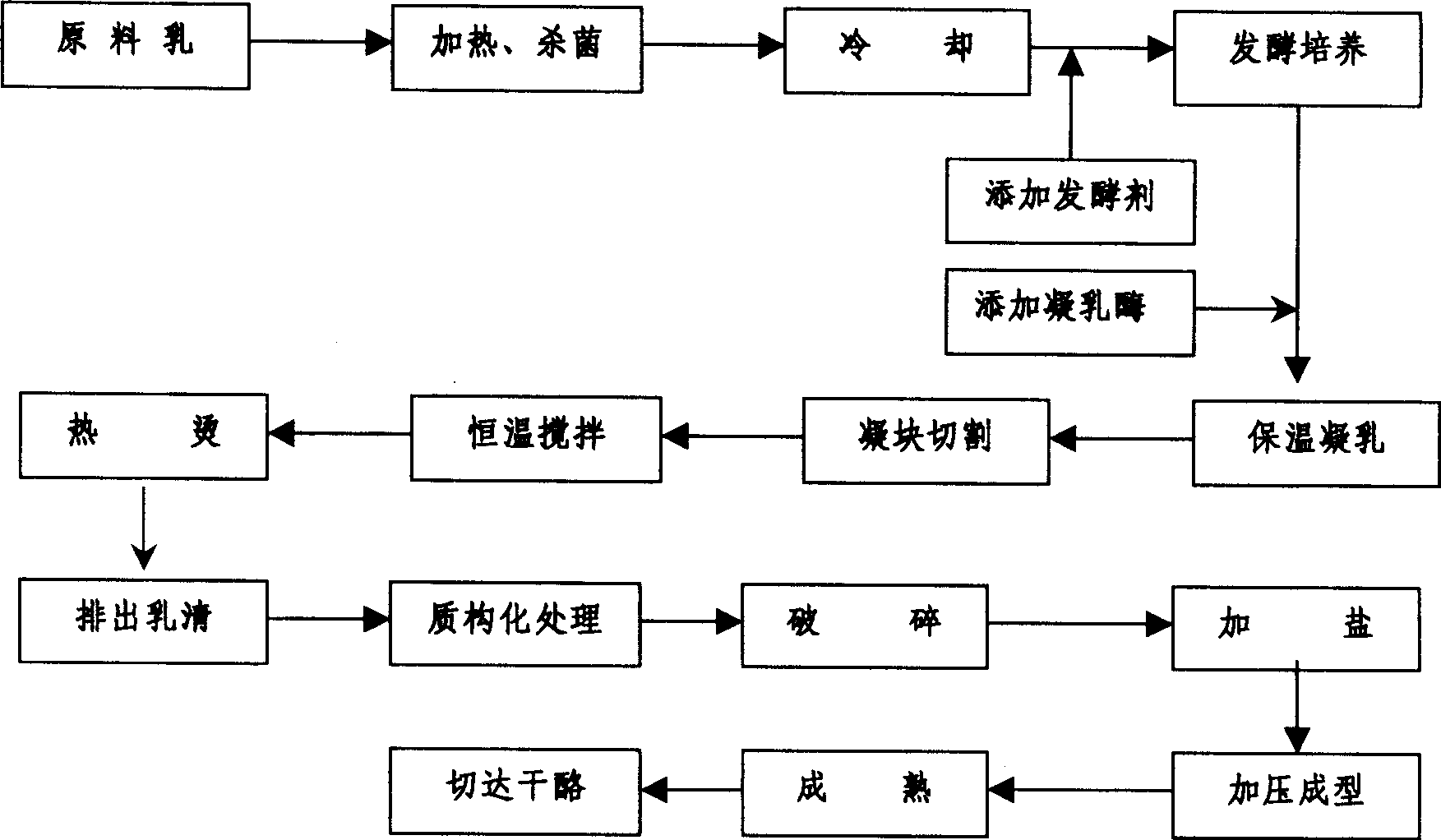

[0027] A preferred embodiment of the cheddar cheese manufacturing system in the present invention is shown in FIG. 1 , which includes a material heating system 1 , a fermented curd system 2 , a texturing system 3 , a salinization system 4 and a pressing system 5 .

[0028] The fermented curd system 2, texturization treatment system 3, salinization system 4 and pressing system 5 are sequentially connected through process delivery pipelines, and the raw materials are sequentially passed through the manufacturing processes of each system to make cheddar cheese. The raw material here generally refers to raw milk, and the various systems can also be connected by other process conveying devices. After the materials are processed in the previous system, they are transported to the next system for processing. It is best to use closed connections between the various systems.

[0029] The material heating system 1 is connected with the fermented milk system 2, and is used for heating a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com