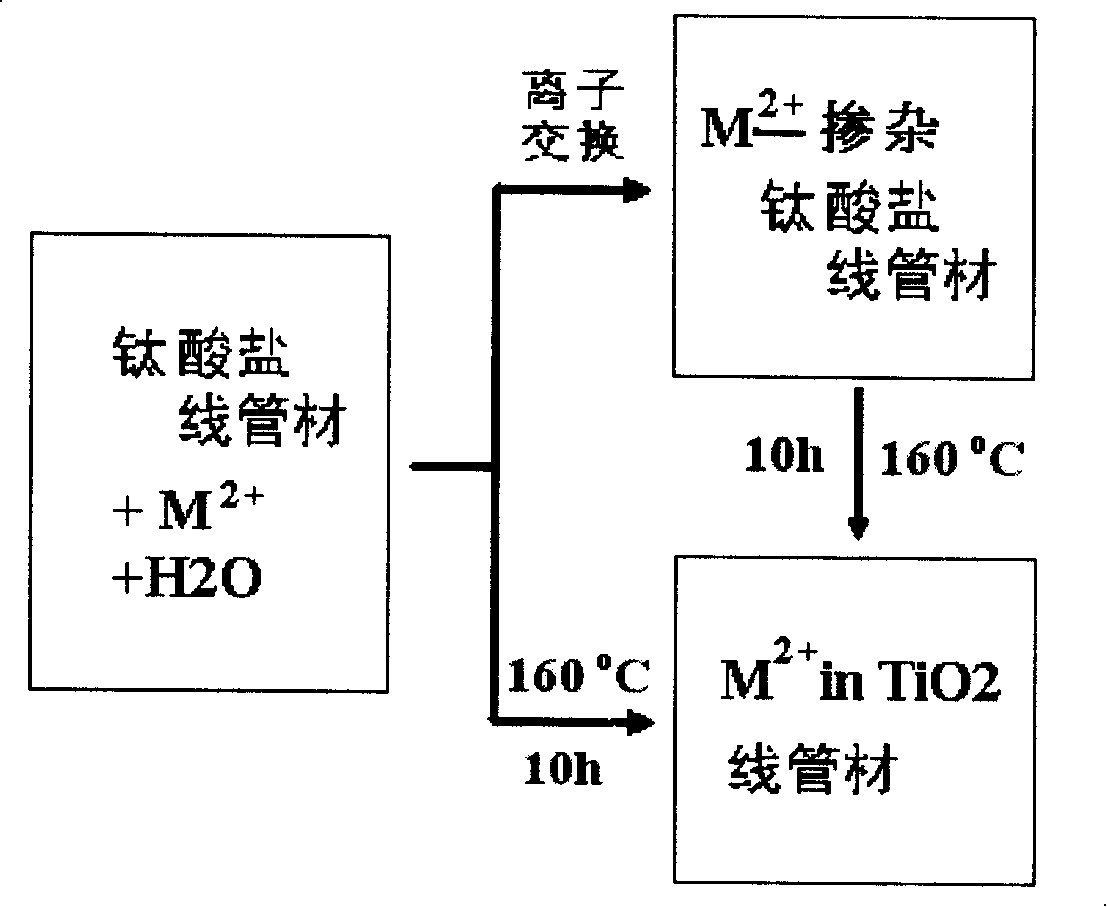

Preparation of metal ion doping titanium dioxide line pipe by ion exchange method

A technology of ion exchange and metal ions, which is applied in the field of preparation of doped wire and pipe, can solve problems such as poor effect, and achieve the effect of simple and easy to control, easy to control content, and cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0023] Experimental example 1: 1.0g cadmium chloride (CdCl 2 ) was dissolved in 30mL of water, 1.5g of layered titanate (Na-Ti-O) line pipe was added, ion exchange was carried out at 100°C for 15h, cooled to room temperature, filtered, and washed with water to obtain the ionic Cd 2+ layered titanate wire tubing. Take 1.5g of the exchanged pipe material and put it into the reaction solution, add 30mL of water, and react at 160°C for 10h to prepare Cd 2+ ion-doped TiO 2 wire tubing.

experiment example 2

[0024] Experimental example 2: 1.0g manganese chloride (MnCl 2 ) was dissolved in 30mL of water, 1.5g of layered titanate wire pipe (Na-Ti-O) was added, and ion exchange was carried out at 100°C for 15h, cooled to room temperature, filtered, and washed with water to obtain Mn-containing 2+ Ionic layered titanate wire tubing. Take 1.5g of the exchanged pipe material and put it into the reaction solution, add 30mL of water, and carry out the reaction at 160°C for 10h to obtain Mn 2+ ion-doped TiO 2 wire tubing.

experiment example 3

[0025] Experimental example 3: 1.0g manganese acetate (Mn(Ac) 2 ) was dissolved in 30mL of water, 1.5g of layered titanate wire pipe (Na-Ti-O) was added, and ion exchange was carried out at 100°C for 15h, cooled to room temperature, filtered, and washed with water to obtain the ionic Cd 2+ layered titanate wire tubing. Take 1.5g of the exchanged pipe material and put it into the reaction solution, add 30mL of water, and carry out the reaction at 160°C for 10h to obtain Mn 2+ ion-doped TiO 2 wire tubing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com