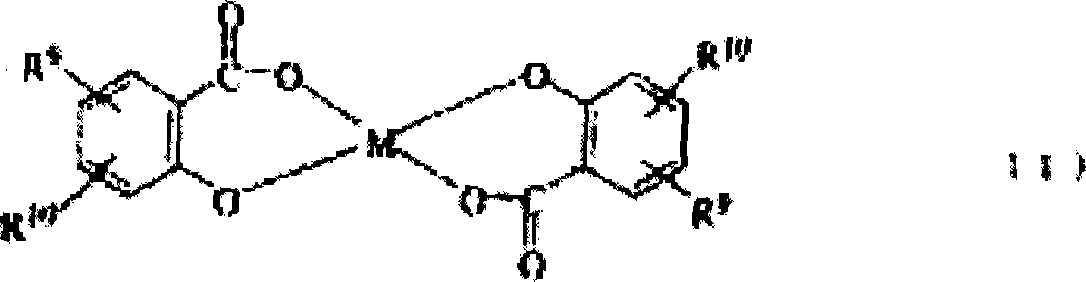

Process for producing toner for electrophotography

一种制造方法、电子照相的技术,应用在显影剂、电记录术、光学等方向,能够解决没有调色剂带电发生部位、易带电等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0179] Production example 1 (manufacture of polyester A)

[0180] Polyoxypropylene (2.2)-2,2-bis(4-hydroxyphenyl)propane 8320g, polyoxyethylene (2.0)-2,2-bis(4-hydroxyphenyl)propane 80g, terephthalic acid 1592g And 32g of dibutyltin oxide (esterification catalyst) was added into a four-necked flask equipped with a nitrogen inlet tube, a dehydration tube, a stirrer and an electric thermocouple, in a nitrogen atmosphere, at 230°C under normal pressure (101.3kPa) The reaction was carried out under reduced pressure for 5 hours, and then further reacted under reduced pressure. After cooling to 210° C., 1672 g of fumaric acid and 8 g of hydroquinone were added, and reacted for 5 hours, polyester resin A was obtained by further reacting under reduced pressure. The softening point of polyester A was 110° C., the glass transition point was 66° C., the acid value was 24.4 mgKOH / g, and the number average molecular weight was 3,760.

manufacture example 2

[0181] Production example 2 (manufacture of polyester B)

[0182] Polyoxypropylene (2.2)-2,2-bis(4-hydroxyphenyl)propane 1750g, polyoxyethylene (2.0)-2,2-bis(4-hydroxyphenyl)propane 1625g, terephthalic acid 1145g , 161g of dodecenyl succinic anhydride, 480g of trimellitic anhydride and 26g of tin 2-ethylhexanoate were added to a four-necked flask equipped with a nitrogen inlet tube, a dehydration tube, a stirrer and a thermocouple, and in a nitrogen atmosphere at 220 The polyester resin B was obtained by stirring and reacting until the softening point measured in accordance with ASTM D36-86 was 120°C. Polyester B had a softening point of 121° C., a glass transition point of 65° C., an acid value of 21 mgKOH / g, and a number average molecular weight of 3,394.

manufacture example 3

[0183] Manufacturing Example 3 (Manufacturing of Master Batch A)

[0184] Add 70 parts by weight of fine powder of polyester A obtained in Production Example 1 and 30 parts by weight of a copper phthalocyanine slurry pigment (ECB-301: solid content 46.2% by weight) manufactured by Dainippon Seika Chemical Co., Ltd. Mix in mixer for 5 minutes to moisten. Then, the mixture was put into a kneading mixer and slowly heated. The resin is melted at about 90-110°C, kneaded in the presence of water, and kneaded continuously at 90-110°C for 20 minutes while evaporating the water.

[0185] Then, kneading was continued at 120° C. to evaporate the remaining water, and then dehydrated and dried. Furthermore, kneading was continued for 10 minutes under the condition of 120-130 degreeC. After cooling, kneading, cooling, and coarse crushing were performed with a heated three-roll mill to obtain a coarsely crushed product (masterbatch A) of a high-concentration coloring composition containin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com