Dynamoelectric system safety analyzing device and method based on cause-effect network model

A causal network model and security analysis technology, applied in the direction of electrical testing/monitoring, etc., can solve problems such as difficult to determine the safety-sensitive parts of the equipment system and cannot guarantee accuracy, and achieve the effect of enhancing stability and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

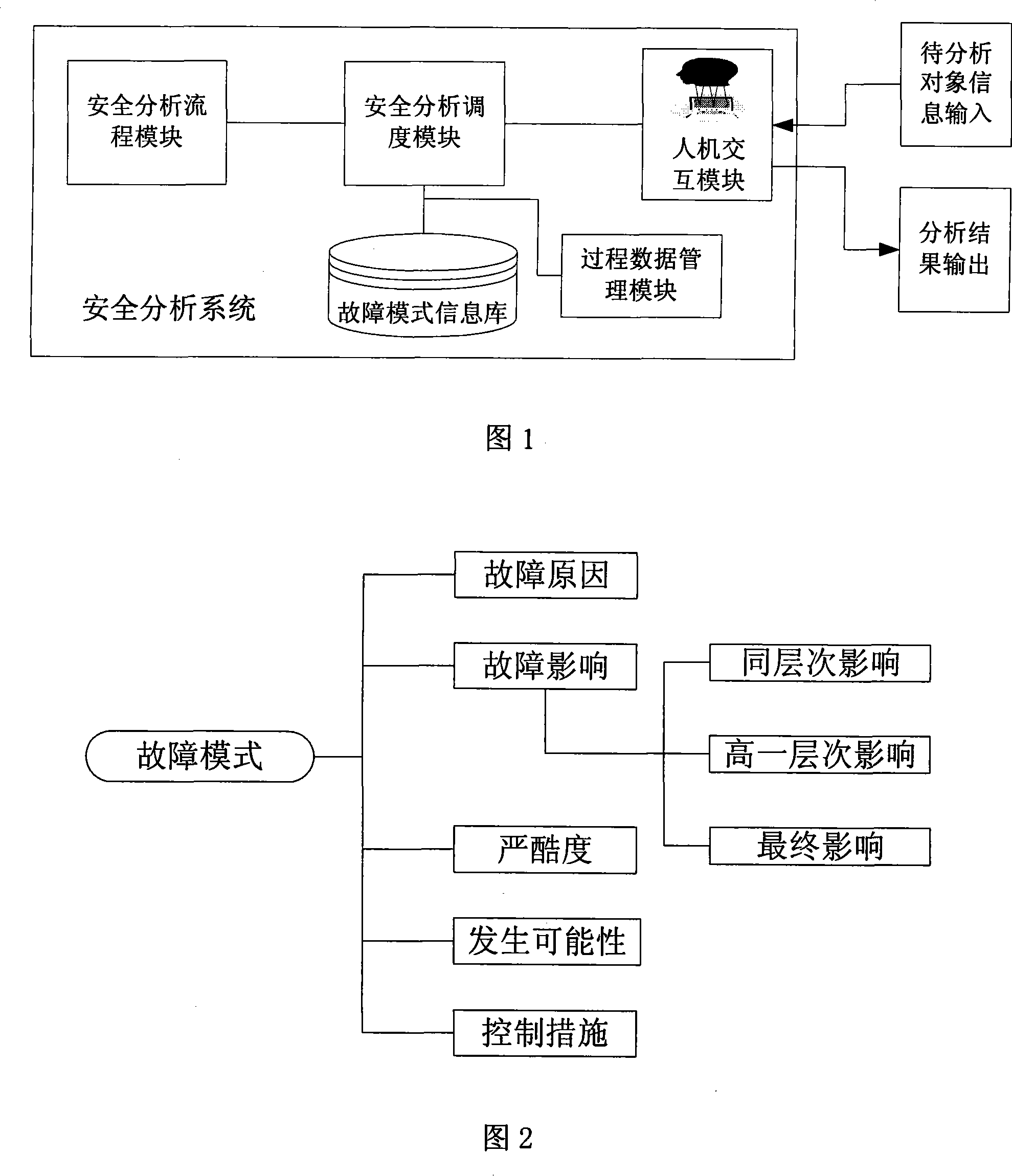

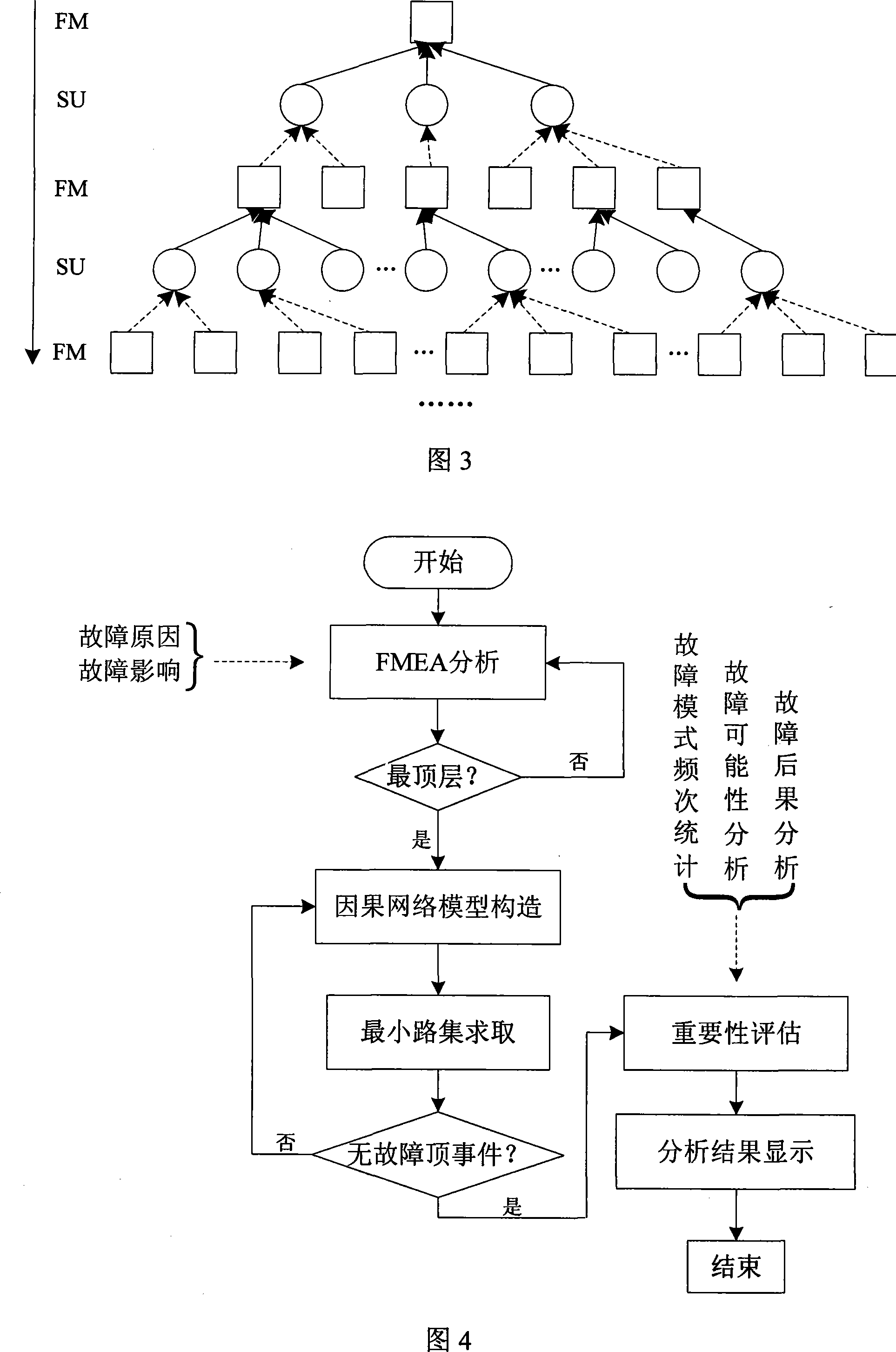

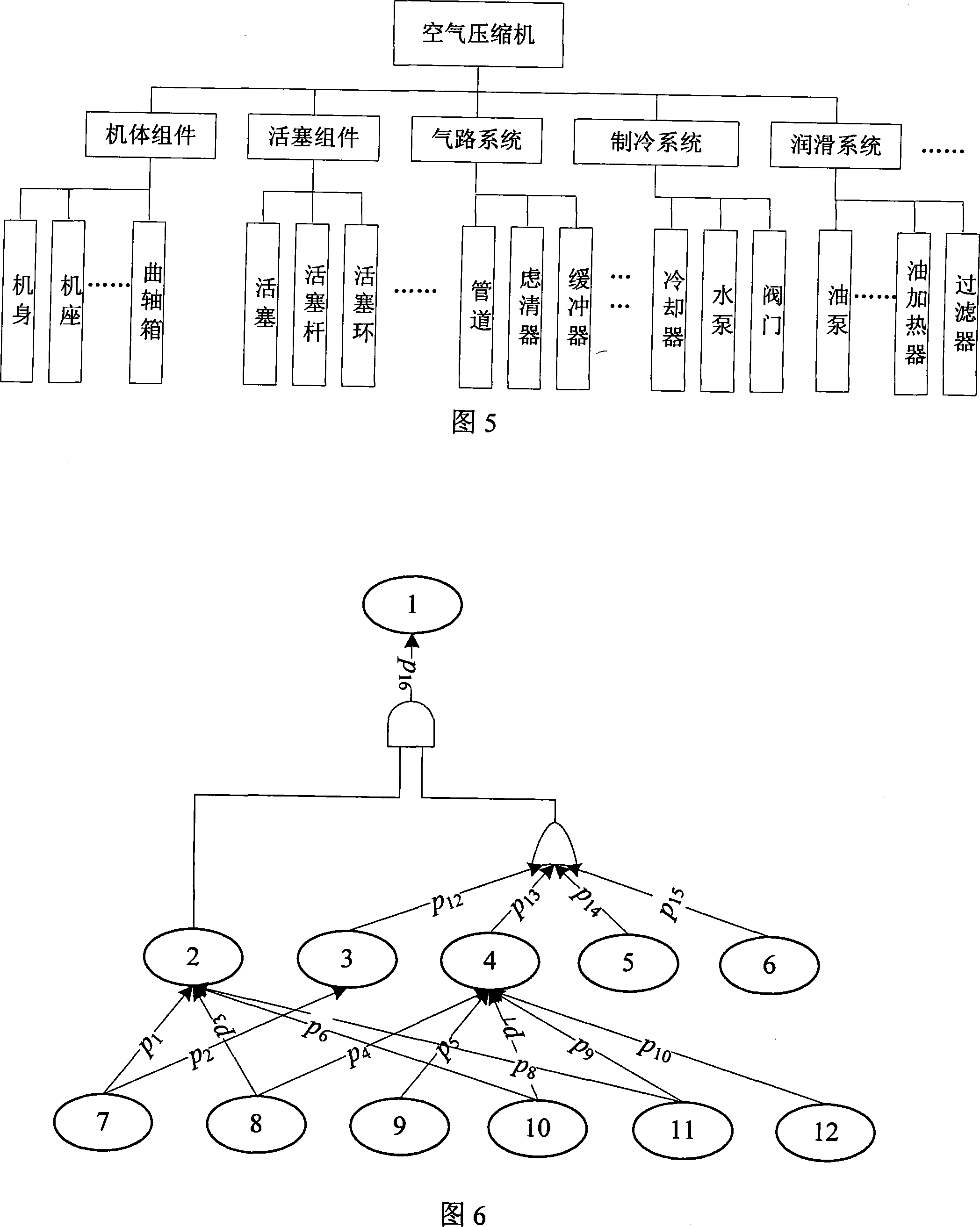

[0028] At first failure mode and influence analysis in the present invention, causal network model and minimum road set are defined as follows:

[0029] Failure Mode and Effect Analysis (FMEA for short): refers to the analysis of the subsystems, components and other components of the product one by one during the product design process to find out all possible potential failure modes and analyze their possible causes and consequences. It is a systematic activity to analyze its hazards, take measures in advance, reduce its severity, and reduce the probability of its occurrence, so as to improve product reliability.

[0030] The traditional form-based FMEA is a single-mode analysis method, which only analyzes single-point faults without considering multiple faults. In addition, FMEA only analyzes the causes, effects and hazards of failures, but does not consider the identification of security-sensitive links in the system, which is precisely the guarantee for enterprises to real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com