Method for producing white goat wool quilt

A technology of white goat cashmere and its manufacturing method, which is applied in the field of cashmere products, can solve the problems of difficult use and single use of middle goat cashmere, and achieve the effect of good internal appearance, uniform layout and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

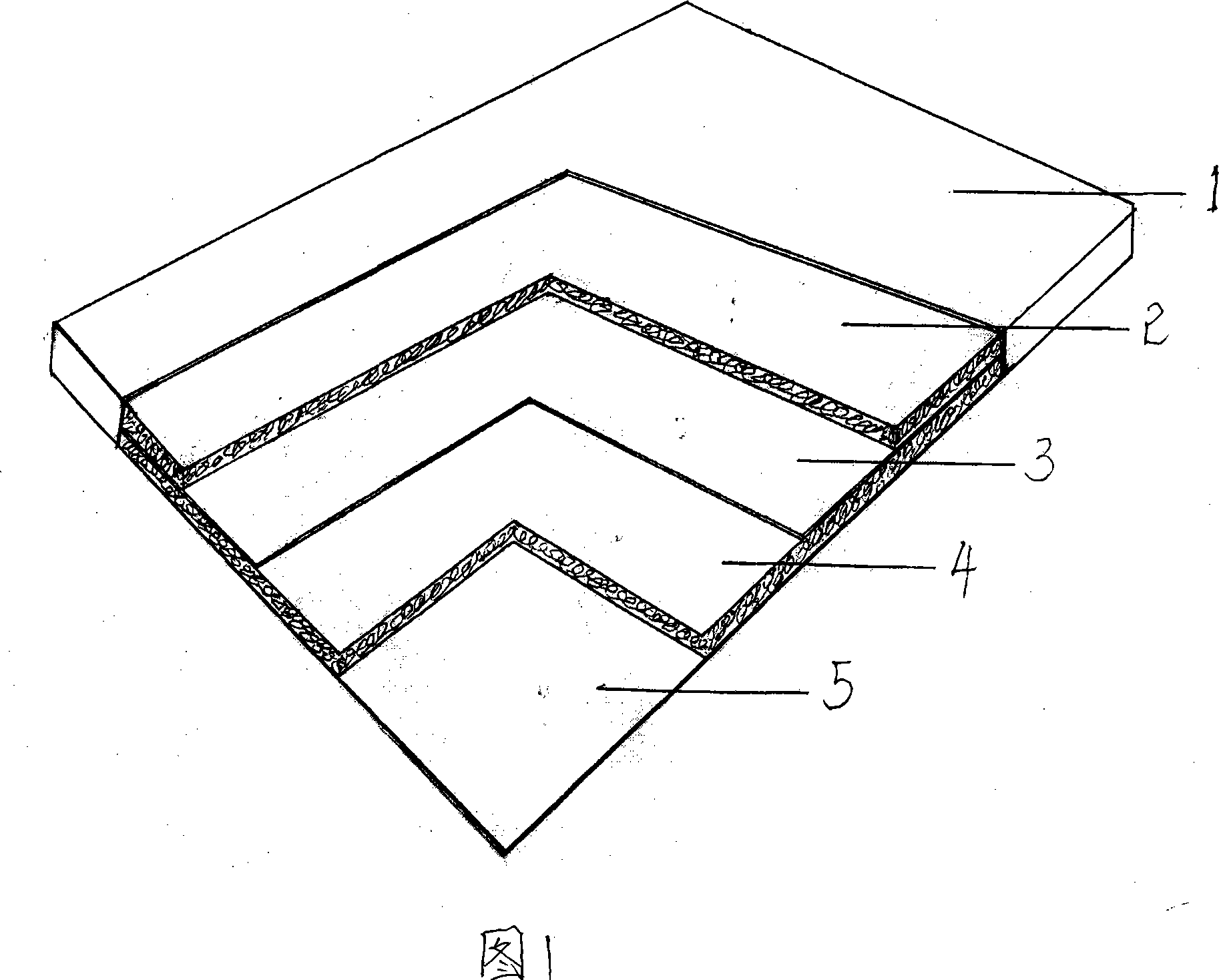

Image

Examples

Embodiment 1

[0024] Embodiment 1, a kind of manufacture method of white goat cashmere quilt comprises the following steps,

[0025] 1. Processing of raw white goat cashmere: Maonengjing, 127, cashmere lotion KTF350, Pingpingjia, softener AG150E, cashmere anti-moth agent JF86 are all conventional products on the market that are familiar and often used by those skilled in the art.

[0026] 1.1. Washing:

[0027] The first step of washing process: calculated on the basis of the weight of white cashmere after passing the wheel, the amount of Monogen (Monogen) is 3%; the amount of 127 is 3%; the amount of sodium tripolyphosphate is 3%; the liquor ratio is 1:30; Value 7.0; temperature 35°C, time 20min,

[0028] The second step of washing process: cashmere lotion KTF350, the dosage is 3%; whitening agent 0.5%; liquor ratio 1:30; pH value 7; temperature 30°C, time 25min.

[0029] White cashmere is raw cashmere grabbed from white goats, and it has coarse goat hair (the fineness of cashmere is 13-...

Embodiment 2

[0051] Embodiment 2, a kind of manufacture method of white goat cashmere quilt, step is the same as embodiment 1, difference is following specific parameter

[0052] 1.1, washing,

[0053] The first step of washing process: calculated according to the weight of white cashmere after passing through the wheel, the net amount of wool energy is 4%; the amount of 127 is 4%; the amount of sodium tripolyphosphate is 5%; the liquor ratio is 1:40; ℃, time 30min,

[0054] The second step of washing process: cashmere lotion KTF350, the dosage is 5%; whitening agent 2%; liquor ratio 1:40; pH value 8; temperature 40°C, time 40min. The whitening agent can be hydrogen peroxide, hydrosulfite and strong bleaching agent, and when using strong bleaching agent, 4-5% by weight auxiliary agent such as sodium pyrophosphate can be added.

[0055] 1.2, carding white cashmere,

[0056] When carding the washed cashmere on the A181 cashmere carding equipment, the parameters of each link are: moisture ...

Embodiment 3

[0060] Embodiment 3, a kind of manufacture method of white goat cashmere quilt, the steps are the same as embodiment 1, the difference lies in the specific parameters

[0061] 1.1, washing,

[0062] The first step of washing process: calculated according to the weight of white cashmere after the wheel, the net amount of wool energy is 3.5%; the amount of 127 is 3.5%; the amount of sodium tripolyphosphate is 4%; the liquor ratio is 1:35; the pH value is 8; the temperature is 40 ℃, time 25min,

[0063] The second step of washing process: cashmere lotion KTF350, the dosage is 4%; whitening agent 1%; bath ratio 1:35; pH value 7.5; temperature 35 ℃, time 30min. Brighteners can be hydrogen peroxide, hydrosulfite, and strong bleach. When using strong bleaching agent, you can also add 4-5% weight ratio of additives such as: sodium oxalate.

[0064] 1.2, carding white cashmere,

[0065] When carding the washed cashmere on the A181 cashmere carding equipment, the parameters of each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com