Heavy liquid discarding tailings processing for improving processing capacity of lead-zinc concentrator

A technology of ore dressing plant and processing capacity, applied in solid separation, wet separation, chemical instruments and methods, etc., can solve problems such as impact, and achieve the effect of reducing ore volume, optimizing ore dressing process, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] 1. Remove the ore smaller than 210 microns in the ore;

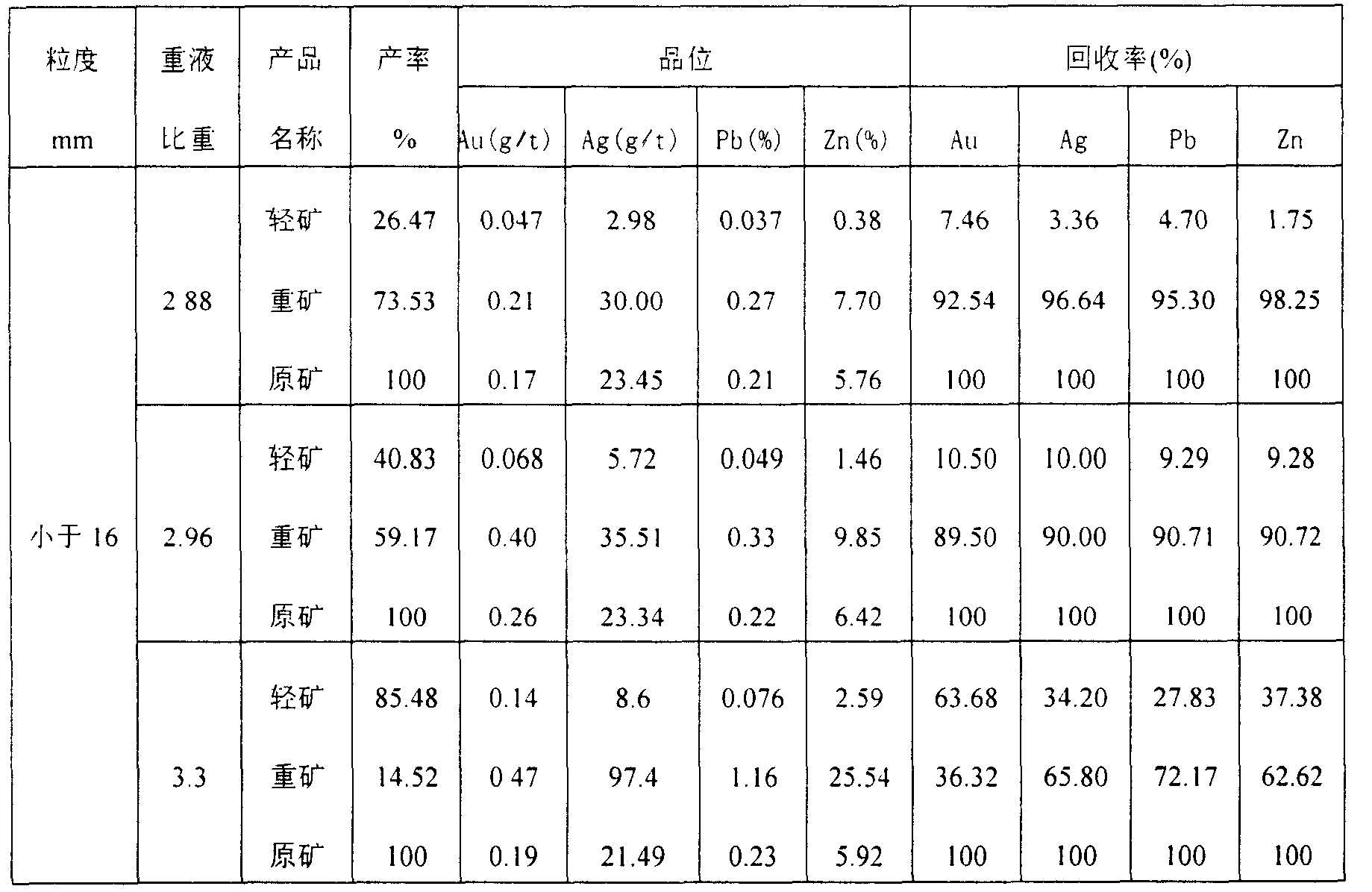

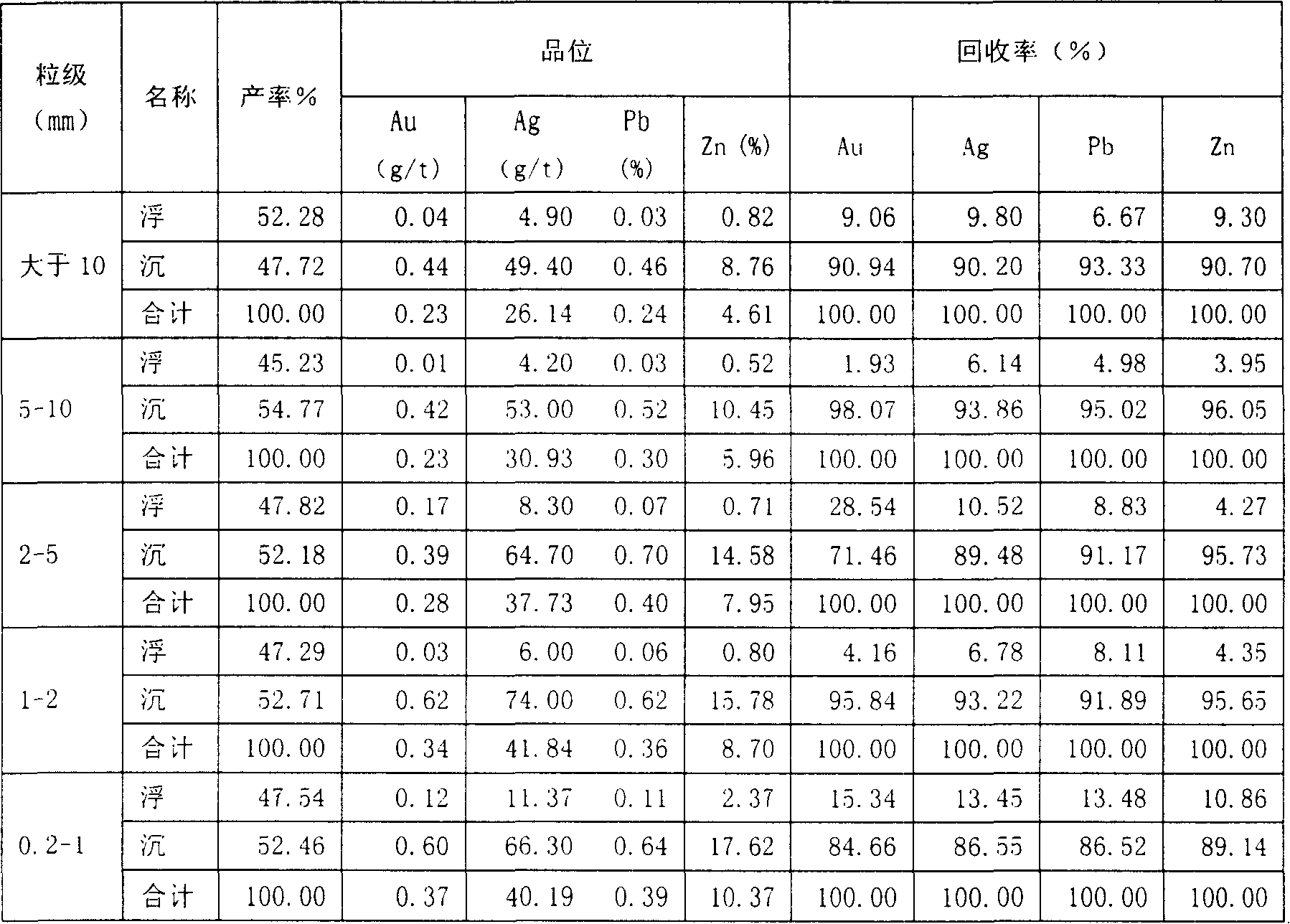

[0020] 2. The specific gravity of selected heavy liquid is 2.88g / cm 3 , 2.96g / cm 3 and 3.3g / cm 3 Separation test of the heavy liquid.

[0021] 3. Add the ore to the container containing the heavy liquid, and then stir to make all the ore wet in the heavy liquid. Note that the amount of ore must ensure that the separation interface of light and heavy minerals can be clearly seen when the stirring is stopped. For the separation of light and heavy minerals in the next step.

[0022] 4. Stop stirring to make the ore stratify in the heavy liquid according to the different specific gravity.

[0023] 5. Take out the light ore floating on the heavy liquid and dry it.

[0024] 6. Take out the ore sinking at the bottom of the heavy liquid and dry it.

[0025] 7. Carry out the heavy liquid separation test of other grades of ores in turn.

[0026] 8. Weigh the obtained ores of different grades and analyze the content ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com