An environmentally friendly and efficient resource recovery process for low-grade matte slag

A resource recovery, low-grade technology, applied in the direction of process efficiency improvement, etc., can solve the problems of difficult Fe slag treatment, separation and purification, high leaching costs, etc., to achieve resource recovery, reduce the amount of ore to be processed, and achieve high economic efficiency. value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

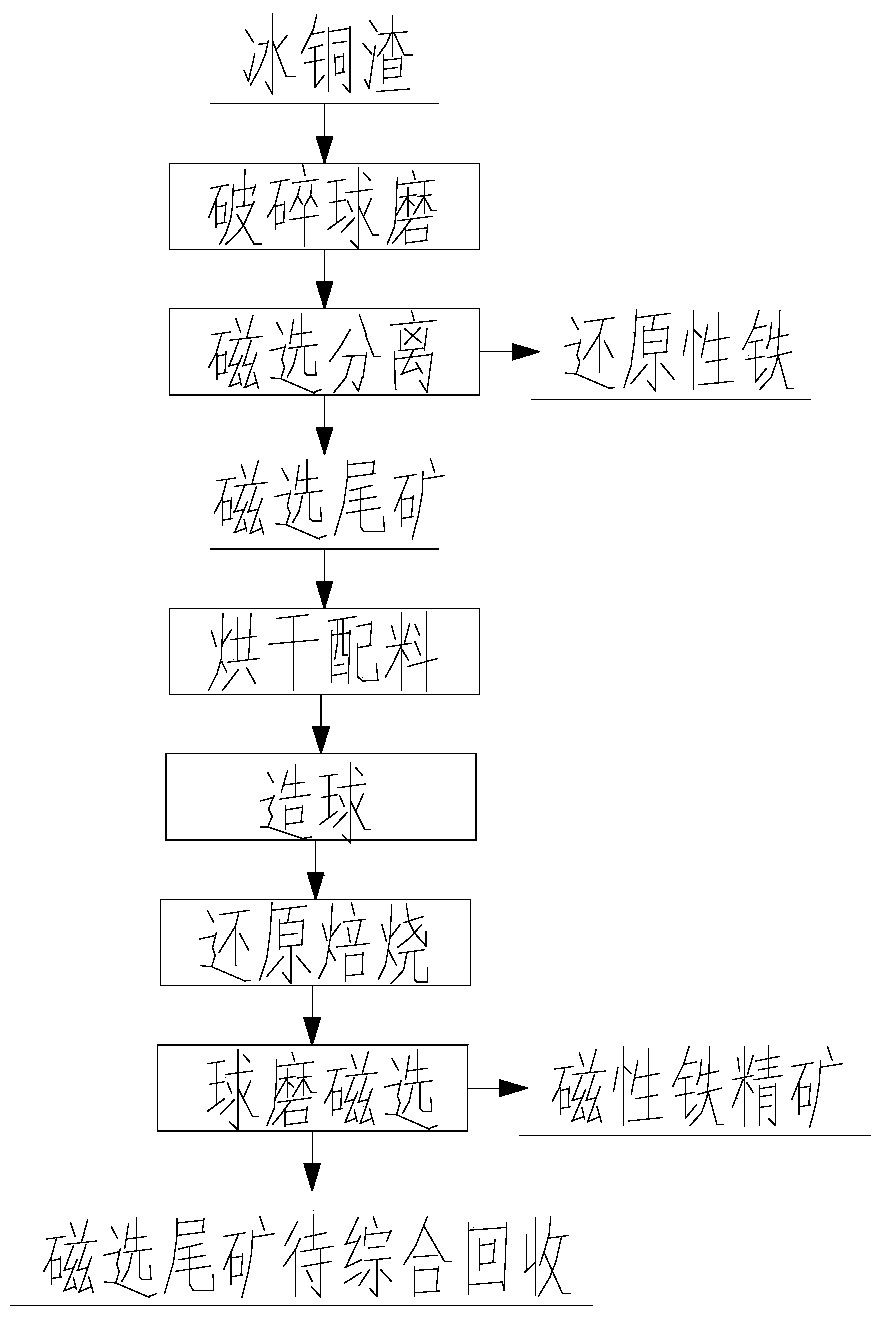

Method used

Image

Examples

Embodiment 1

[0019] A kind of processing technology for the copper matte slag roasting and magnetic separation to recover iron and enrich other metal resources. The matte slag produced by a factory in Chenzhou, Hunan Province is used. The elemental composition analysis is shown in Table 1. The Fe content in the matte slag reaches 48.62%. . Take 30kg sample crushed ball mill to 100%<0.0744mm, magnetic separation with 500GS magnetic field intensity, the iron concentrate rate is 19.22%, and the Fe grade of concentrate reaches 69.39%.

[0020] Table 1 Elemental analysis of matte slag (%)

[0021] Cu

[0022] After the magnetic separation tailings are dehydrated, dried and pulverized, the reduced coal powder, sodium humate, and bentonite are added in a ratio of 1:0.2:0.05:0.05, respectively, and stirred and mixed, and then magnetized and roasted in a laboratory rotary kiln at 750 °C. After 60min, the roasting material is ball-milled and magnetically separated, the iron concentrate ra...

Embodiment 2

[0028] The matte slag produced by a factory in Zhuzhou City, Hunan Province was used, and the elemental analysis is shown in Table 3.

[0029] Table 3 Elemental analysis of matte slag (%)

[0030] Cu

Pb

Zn

Ag

Fe

W

0.59

2.07

7.72

0.005

40.35

2.31

[0031] Weigh 30kg of samples and crush them to 100%<0.0744mm, and magnetically separate them with 500GS magnetic field. The iron concentrate rate is 25.11%, and the Fe grade of the concentrate reaches 65.17%.

[0032] After the magnetic separation tailings are dehydrated, dried and pulverized, reduced coal powder, sodium humate and bentonite are added in a weight ratio of 1:0.2:0.05:0.05, respectively, and stirred and mixed, and magnetized in a laboratory rotary kiln at 750 °C. After roasting for 60min, the roasting material is ball-milled and then magnetically separated. The iron concentrate rate is 42.0%, which is 31.45% of the original processing capacity, and the iron concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com