Iron-separating and sulfur-removing enrichment method of high-sulfur hematite

A hematite, high-sulfur technology, applied in solid separation and other directions, can solve the problems of reducing iron recovery rate, difficult to reduce sulfur content, difficult sulfur content, etc., to ensure iron recovery rate, reduce the amount of processed ore, and reduce sorting cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: the high-sulfur low-grade hematite of the present embodiment, Fe grade 19.52%, iron mainly exists with hematite form, and iron distribution rate is 78.27% in hematite; Harmful element S content 1.96% in this ore, Seriously exceeding the standard, S mainly occurs in the form of pyrite, and partly occurs in pyrrhotite; gangue minerals are mainly quartz, dolomite and calcite. If the traditional technological process is used for sorting, it is difficult to reduce S to the qualified requirement, and the iron recovery rate is greatly affected during the desulfurization process;

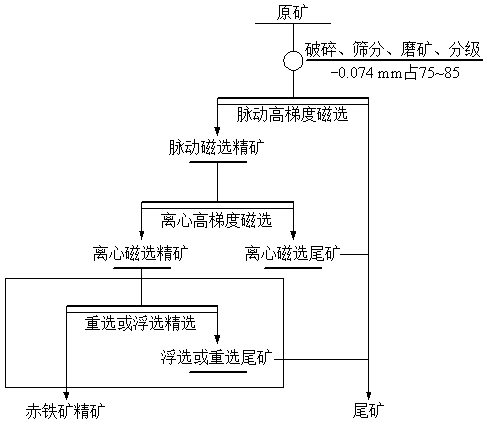

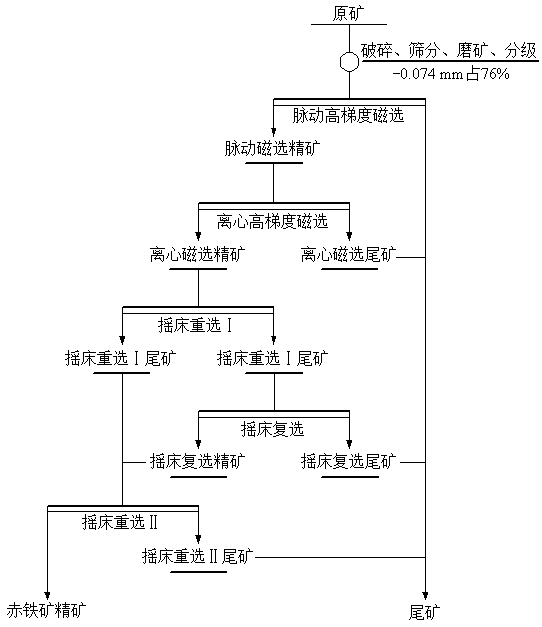

[0031] Such as figure 1 and 2 Shown, a kind of high-sulfur hematite iron separation and desulfurization enrichment method, concrete steps are as follows:

[0032] (1) Crushing, screening, grinding, and grading high-sulfur hematite raw ore to -0.074mm accounts for 76% to obtain fine-grained hematite;

[0033] (2) The fine-grained hematite in step (1) is subjected to pulsating high-gra...

Embodiment 2

[0047] Embodiment 2: The rough concentrate of high-sulfur hematite in this example is obtained by pulsating high-gradient magnetic separation at the production site; the grade of Fe in the rough concentrate of high-sulfur hematite is 41.85%, and the content of harmful element S is 0.57%. Exist in the form of iron ore and pyrrhotite; gangue minerals are mainly quartz;

[0048] Such as figure 1 and 4 Shown, a kind of high-sulfur hematite iron separation and desulfurization enrichment method, concrete steps are as follows:

[0049] (1) Crushing, screening, grinding, and grading the coarse concentrate of high-sulfur hematite to -0.074mm accounts for 80% to obtain fine-grained hematite coarse concentrate II;

[0050] (2) Perform centrifugal high-gradient magnetic separation on the fine-grained hematite coarse concentrate II in step (1) to obtain centrifugal high-gradient magnetic separation concentrate and centrifugal concentrated tailings; the centrifugal high-gradient magnetic ...

Embodiment 3

[0061] Embodiment 3: In this embodiment, the fine-grained high-sulfur and high-grade hematite has an Fe grade of 31.86%, and iron mainly exists in the form of hematite, and the iron distribution rate in the hematite is 75.34%; the harmful element S content in the ore is 1.12% , the content exceeds the standard, sulfur mainly occurs in the form of pyrite and pyrrhotite; gangue minerals are relatively simple, mainly quartz and dolomite;

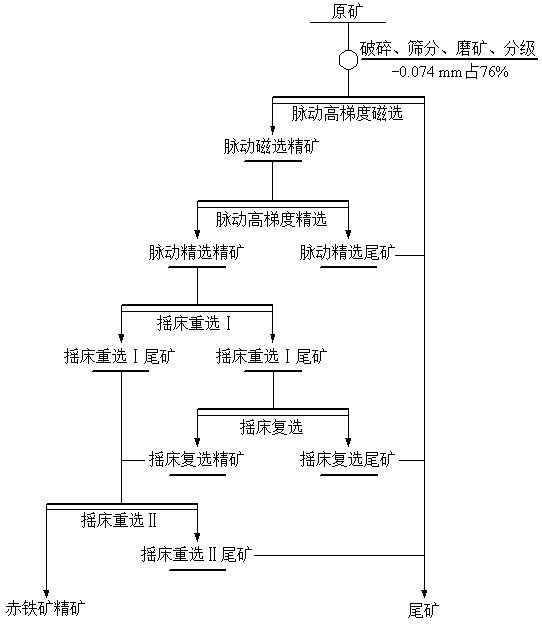

[0062] Such as figure 1 and 6 Shown, a kind of high-sulfur hematite iron separation and desulfurization enrichment method, concrete steps are as follows:

[0063] (1) Crushing, screening, grinding, and grading high-sulfur hematite raw ore to -0.074mm accounts for 85% to obtain fine-grained hematite;

[0064] (2) The fine-grained hematite in step (1) is subjected to pulsating high-gradient magnetic separation rough separation to obtain hematite rough concentrate I and pulsating magnetic separation tailings; wherein the pulsating high-gradient ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com