Cement concrete pouring material for bridge framework

A cement concrete and bridge structure technology, which is applied in the field of cement concrete pouring materials for bridge structures, can solve the problems of lack of specific and unified standards and specifications, achieve the effects of mature production technology, improve early strength, and make up for the slow growth of early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

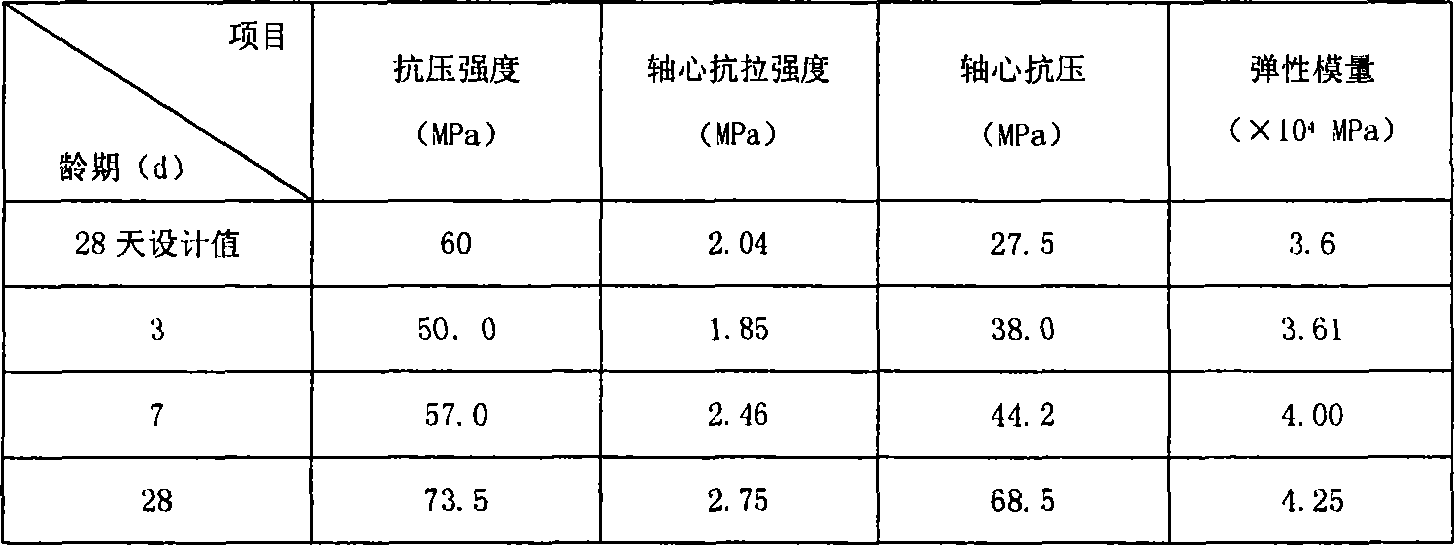

[0009] The present invention will be further described in detail below in conjunction with specific examples.

[0010] 1. Composition and formula

[0011] A cement concrete pouring material for a bridge structure, calculated in kilograms per cubic meter, comprising the following components: 340-469 kg of cement; 722-734 kg of sand; 1038-1061 kg of gravel; 60-120 kg of slag; 40kg; water-reducing agent 13-14; the rest is water, water-binder ratio is 0.28-0.31 [water-binder ratio refers to the weight ratio of water to (cement + slag + silica fume)]; plus polypropylene fiber 0.8kg / m 3 .

[0012] Within the scope of the above formulations, water-binder ratios of 0.31, 0.30, 0.29 and 0.28 were selected respectively to make 4 groups (16 formulations in each group) and 64 examples. The specific compositions are shown in Tables 1, 2, 3 and 4.

[0013] Table 1 Concrete mix when the water-binder ratio is 0.31

[0014]

water-binder ratio

sand rate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com