Wall surface integrated bricks

An integrated and integral technology, applied in covering/lining, building, building structure, etc., can solve the problems of time-consuming and labor-intensive, easy cracking and fouling of tiles, unfavorable development of construction industry, etc., to improve work efficiency, save transportation costs, The effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

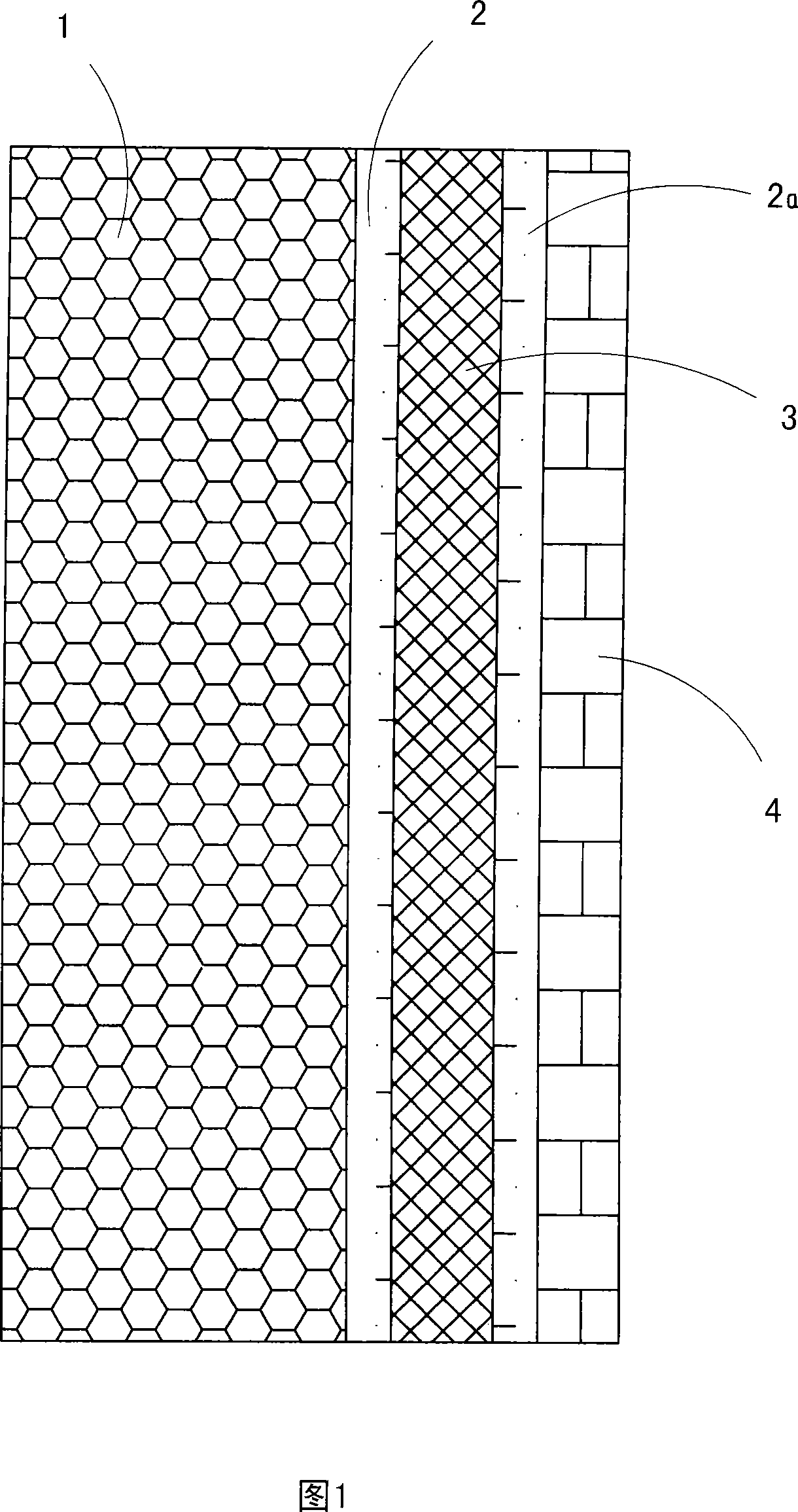

[0020] See Figure 1. The material base 1 of this wall-surface integrated brick is made of polystyrene board with thermal insulation function, such as polystyrene foam board (EPS) or extruded polystyrene board (XPS). Adhesive layer 2 is made of polymer modified plastering mortar, glass fiber mesh layer 3 is made of glass fiber mesh cloth, and the finishing layer is flexible asphalt fiberglass brick layer 4 is made of waterproof and colorful flexible asphalt fiberglass brick. In this way, the exterior wall bricks integrating thermal insulation and waterproof functions are formed. This wall integrated brick can be produced by modern industrial methods, and the overall area can be 930×606mm 2 , or 1000×952mm 2 , or other multiple larger-area specifications, it can be said that such a large-area building finish component has not come out so far.

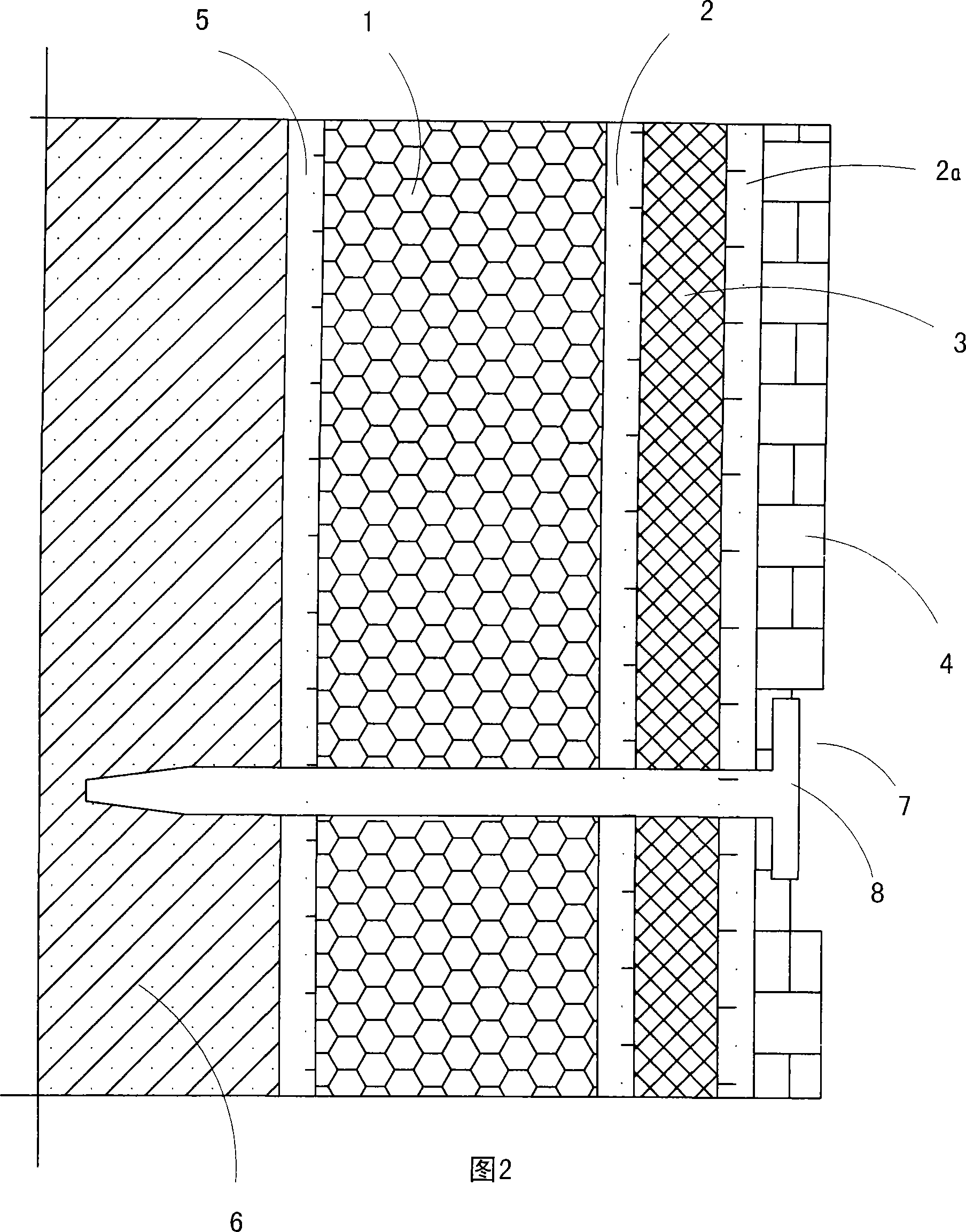

[0021] Referring to Fig. 2, this figure is the construction installation explanatory drawing of product of the present utility model....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com