High-stability thermostatic controller

A thermostatic controller, high-stability technology, used in temperature control, control/regulation systems, non-electric variable control, etc., can solve the problems of low precision and inconvenient use, and achieve reliable work, cost saving, and stable performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

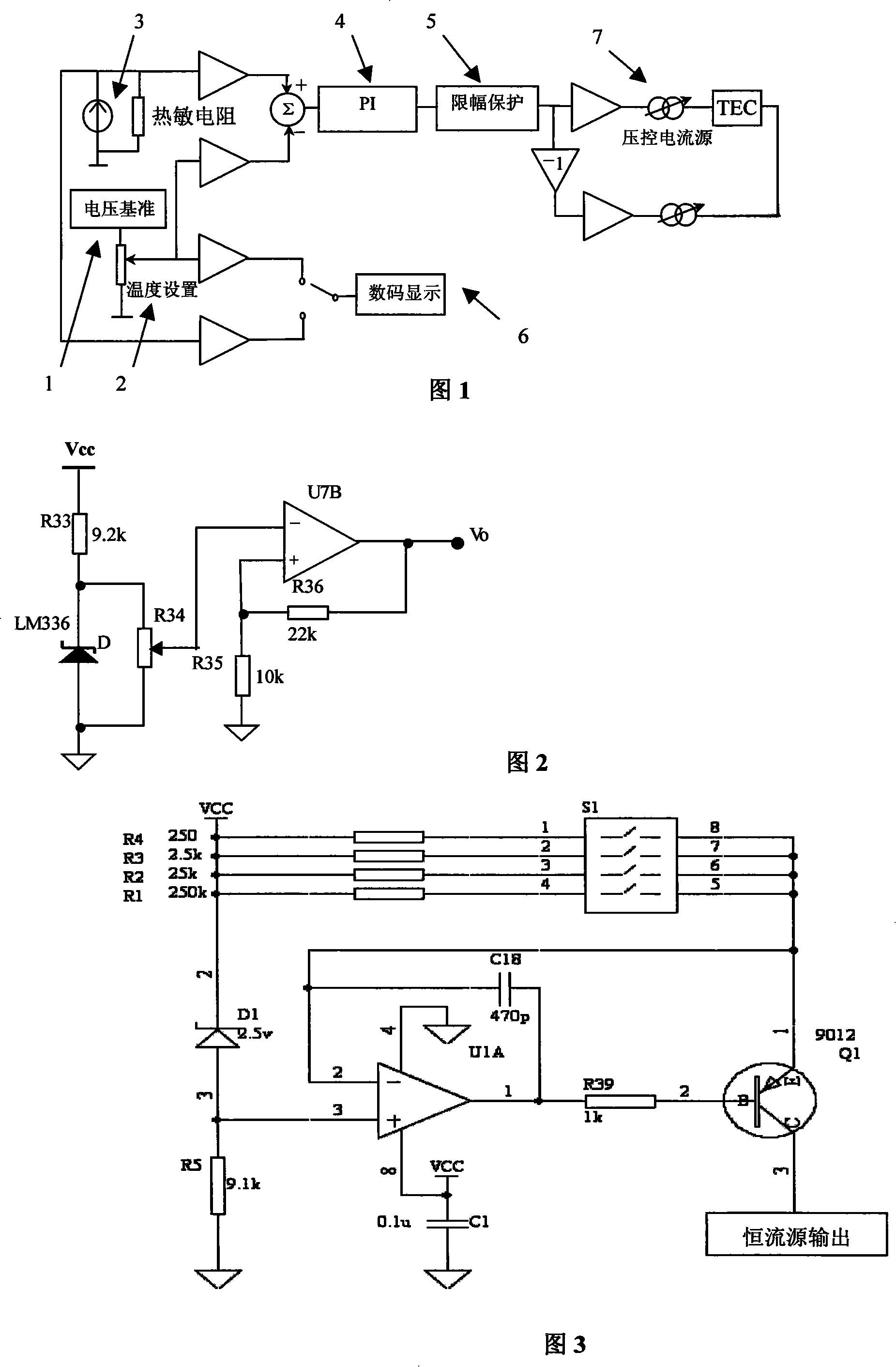

[0038] Embodiment 1 The basic structure and working principle of the high stability constant temperature controller of the present invention

[0039] As shown in Figure 1: the tap output of the potentiometer in the voltage reference circuit (1) is connected to the operational amplifier as a temperature setting circuit (2), and its output is connected to the display circuit (6). The constant current source is connected in series with the temperature sensor, the measuring voltage terminal is connected with the display circuit (6), the temperature setting circuit (2) and the temperature measurement circuit (3) are connected with the subtractor, and the subtractor is connected with the PI control circuit (4), that is, the PI The control modules are connected, and the PI control module is connected with the limiting protection circuit (5). The output of the limiting protection circuit (5) is connected with the TEC driving circuit (7).

[0040] The working principle of the present ...

Embodiment 2

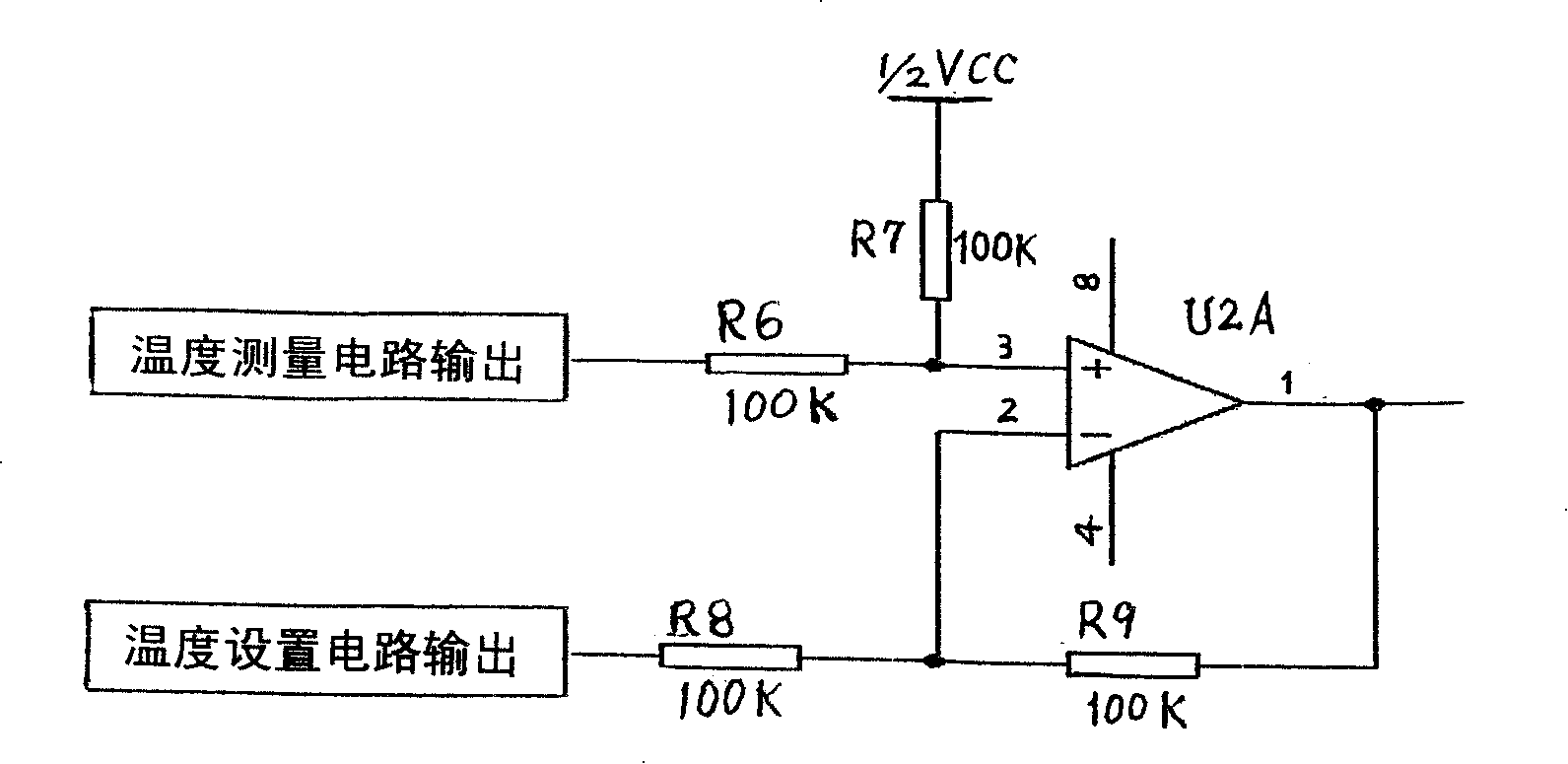

[0046] Embodiment 2 Structure of voltage reference circuit (1) and temperature setting circuit (2)

[0047] As shown in Figure 2, the voltage reference circuit (1) and temperature setting circuit (2) of the present invention include: an external DC power supply (Vcc) is connected to a 9.1k resistor and then connected to a precision voltage reference module (LM336) for grounding; The invented temperature setting circuit (2) is to connect a 10k potentiometer in parallel with the LM336, and its tap is connected to the in-phase input terminal of the operational amplifier U7B; . In addition, in order to improve the driving ability, a voltage follower composed of U2B is added to the output of U7B. The non-inverting input of U2B is connected to the output of U7B, and the inverting input of U2B is connected to its output.

Embodiment 3

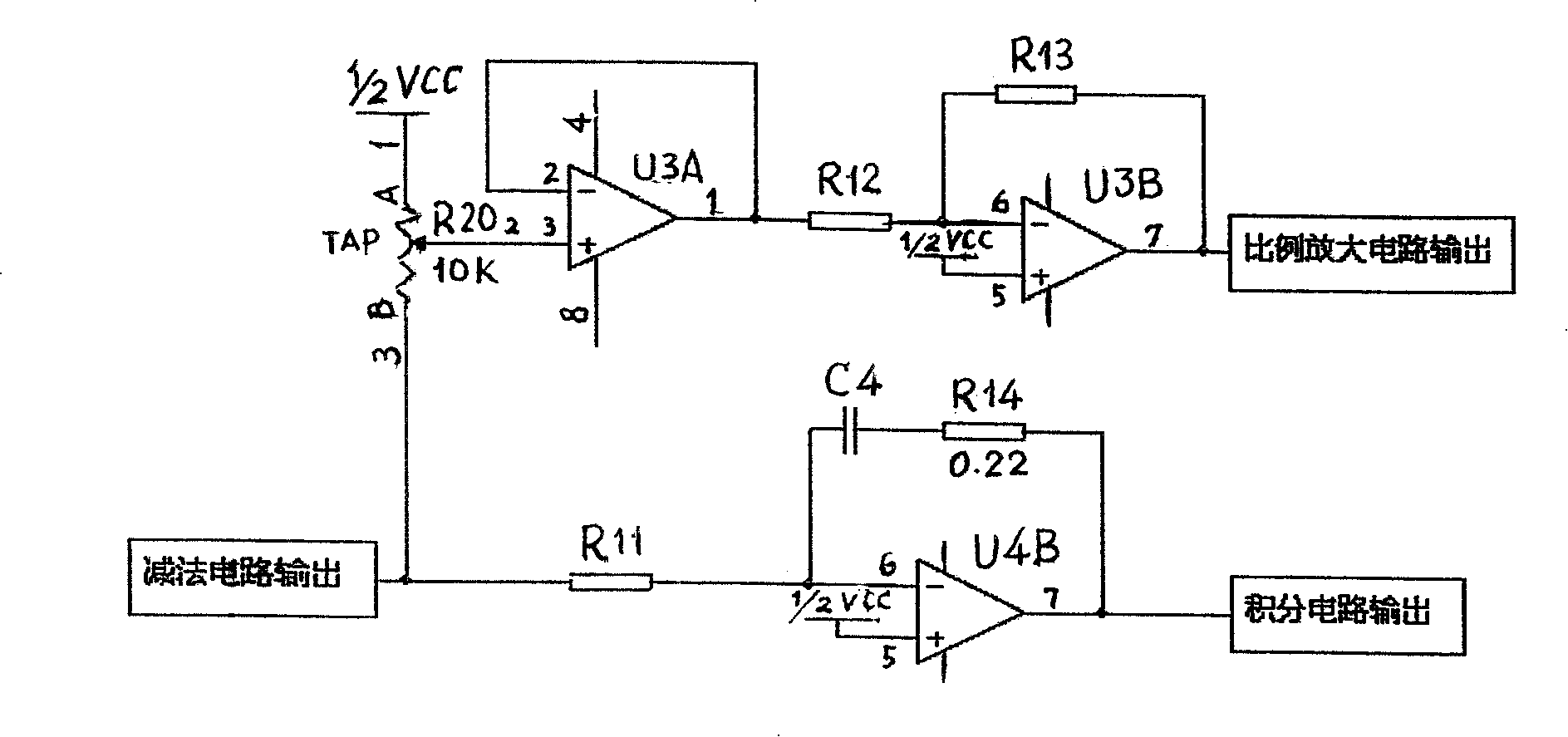

[0048] Embodiment 3 The structure of the temperature measurement circuit (3) of the present invention

[0049] As shown in Figure 3, the temperature measurement circuit (3) of the present invention comprises: external DC power supply (Vcc) connects 2.5V voltage regulator tube D1; The voltage regulator tube D1 anode and the same phase input end of operational amplifier U1A and 9.1k resistance R5 The other end of resistor R5 is connected to ground; the output terminal of operational amplifier U1A is connected to 1k resistor R39 and 470pF capacitor C18; capacitor C18 is connected to the inverting input terminal of operational amplifier U1A, and is connected to four resistors (R1, R2, R3, R4) are connected and connected with the emitter of the triode Q1; the above four resistors (R1, R2, R3, R4) are connected with the external DC power supply (Vcc); the resistor R39 is connected with the base of the triode Q1; the triode The emitter of Q1 is connected with the temperature sensor i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com