Producing method of spruce laminated layer materials

A manufacturing method and technology of laminated timber, which are applied in the direction of wood layered products, wood veneer joining, manufacturing tools, etc., can solve the problems of high cost, occupying land, difficult disposal of waste products, etc., and achieve the effect of simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

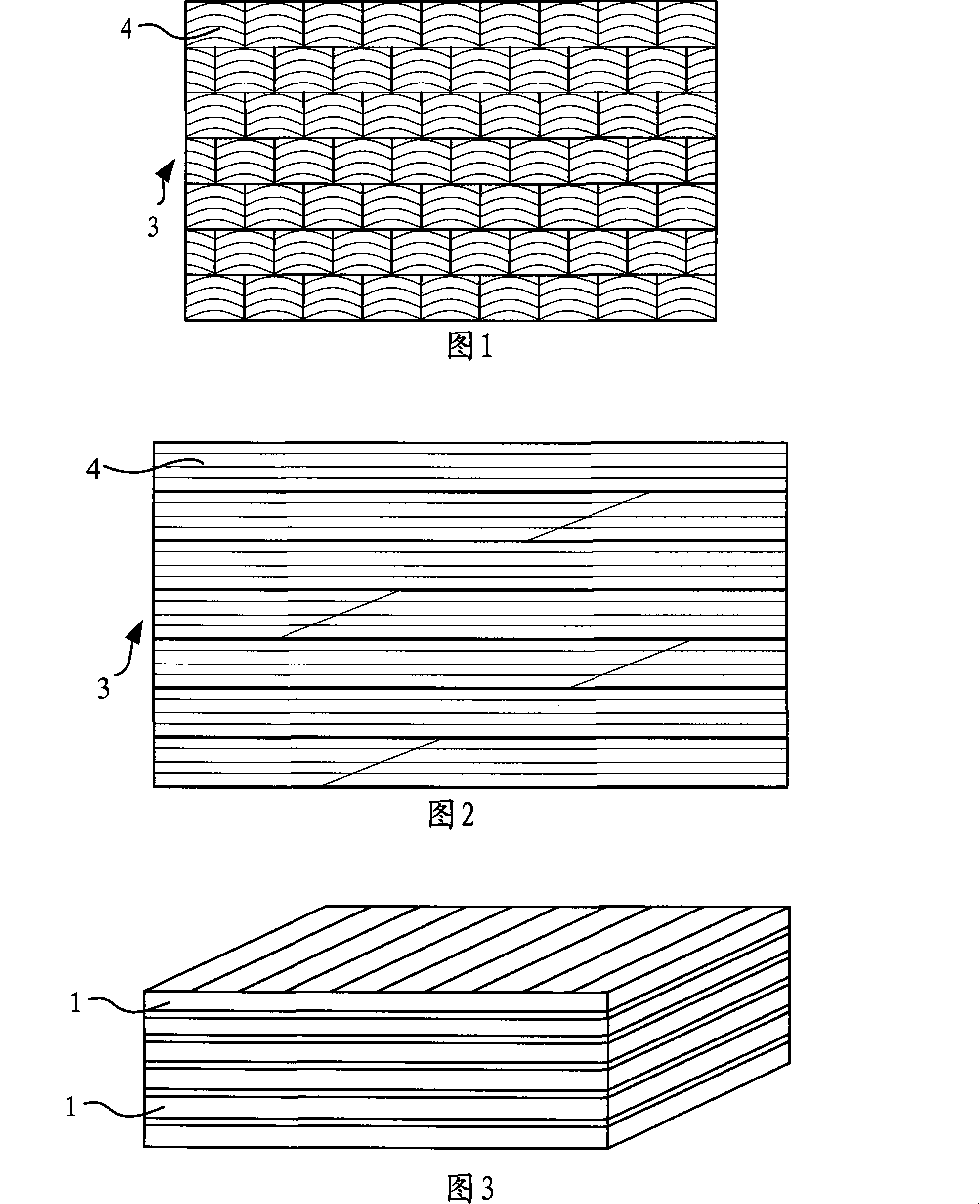

Image

Examples

Embodiment Construction

[0024] The present invention specifically carries out material selection and processing according to the following steps:

[0025] Firstly, according to the patent application 200710178373.8, carry out the grading of the fir sapwood diameter-cut specification board, which specifically includes the following steps:

[0026] Step 1: Select a number of new Chinese fir logs with a diameter of more than 30 cm, a straight trunk, and no defects in appearance (including decay, bending, etc.);

[0027] Step 2: Carry out "rice" font blanking on the selected material;

[0028] Step 3: Saw the standard fir sapwood quarter-cut rough board, dry it in a drying kiln until the moisture content is lower than 12%, remove various wood defects, and finish it into 500mm×20mm×20mm (length×width×thickness) The standard slats are spare;

[0029] Step 4: Through visual inspection, the selected rough plate meets the following requirements: straight texture, uniform material, annual ring width less tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com