Method of preparing multi-component high-frequency thin ferromagnetic film material with component gradient

A ferromagnetic thin film, composition gradient technology, applied in the direction of magnetic layer, magnetic film to substrate application, cathode sputtering application, etc., can solve the problems of increased manufacturing cost, damage to other components, impossible preparation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

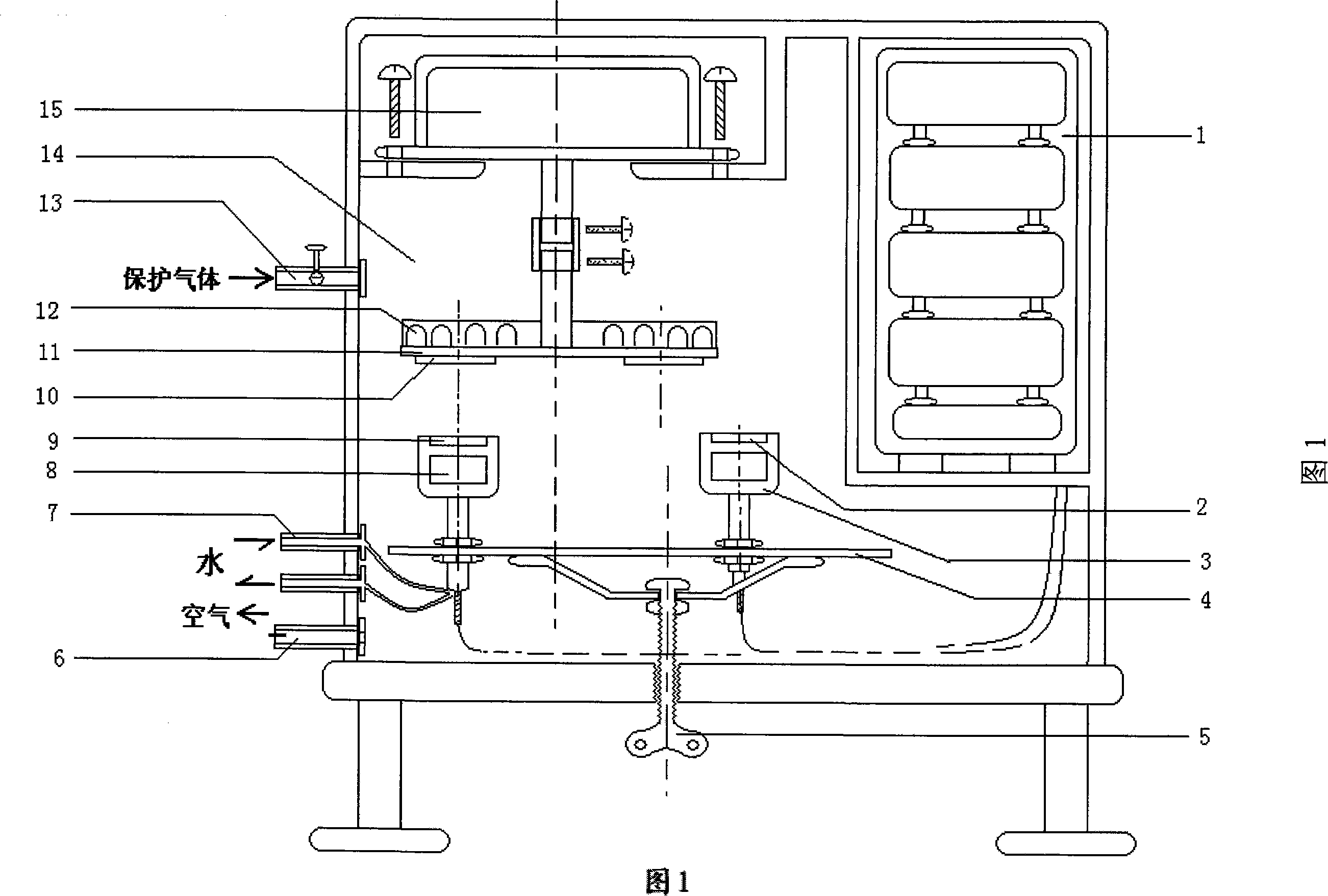

[0048] Preparation (Fe) x -(Nd) y o z film material

[0049] Three main material targets Fe and one dopant target Nd are respectively placed on the main material target base and the dopant target base according to the positions shown in Figure 1, and the target bases are arranged at a central angle of 90 degrees. The substrates 10 to be sputtered are fixed on the lower bottom surface of the circular rotating sputtering sample plate 11 and arranged correspondingly at a central angle of 90 degrees. Start the vacuum control system, when the background vacuum pressure is lower than 5×10 -6 After Torr, feed high-purity Ar gas and Ar / O=10 / 1 mixed gas two-way gas, the Ar gas flow rate is 50 sccm, the Ar / O mixed gas flow rate is 5 sccm, and the circular rotary sputtering is started when the working pressure of the vacuum chamber is 5.8mTorr Plating the sample disk 11, the rotating speed is set at 40 rpm. The sputtering power of the main material target Fe and the dopant target Nd...

Embodiment 2

[0051] Preparation (Fe) x -(Nd 2 o 3 ) y film material

[0052] With reference to the method described in embodiment 1, with Fe as the main material target, with Nd 2 o 3 is the dopant target. Under background vacuum pressure below 5 x 10 -6 After Torr, feed high-purity Ar gas with a flow rate of 20 sccm, and start the circular rotary sputtering sample disk when the working pressure of the vacuum chamber is 2.8 mTorr, and the rotation speed is set to 30 rpm. Main material target Fe and dopant target Nd 2 o 3 The sputtering power is set to 160 and 170W respectively, and the sputtering time is 160 minutes to obtain (Fe) x -(Nd 2 o 3 ) y System of high-frequency ferromagnetic thin film materials.

Embodiment 3

[0054] Preparation (Co) x -(Nd) y N z film material

[0055] Referring to the method described in Example 1, Co is used as the main material target, and Nd is used as the dopant target. The vacuum pressure in the vacuum chamber is lower than 5×10 -6 After Torr, feed high-purity Ar gas and Ar / N=10 / 1 mixed gas two-way gas, the Ar gas flow rate is 50 sccm, the Ar / N mixed gas flow rate is 10 sccm, and the circular rotary sputtering is started when the working pressure of the vacuum chamber is 6.0mTorrr The plated sample disk was set at 50 rpm. The sputtering power of the main material target Co and the dopant target Nd are respectively set to 80 and 130W, and the sputtering time is 60 minutes, and the (Co) x -(Nd) y N z High-frequency ferromagnetic film material of the system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com