Spiral fluorescent tube and manufacturing method therefor

A technology of fluorescent lamp tube and manufacturing method, which is applied in the direction of tube/lamp screen manufacturing, application of luminous paint, etc., can solve the problems of difficult flow of powder slurry, low powder coating efficiency, waste of fluorescent powder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

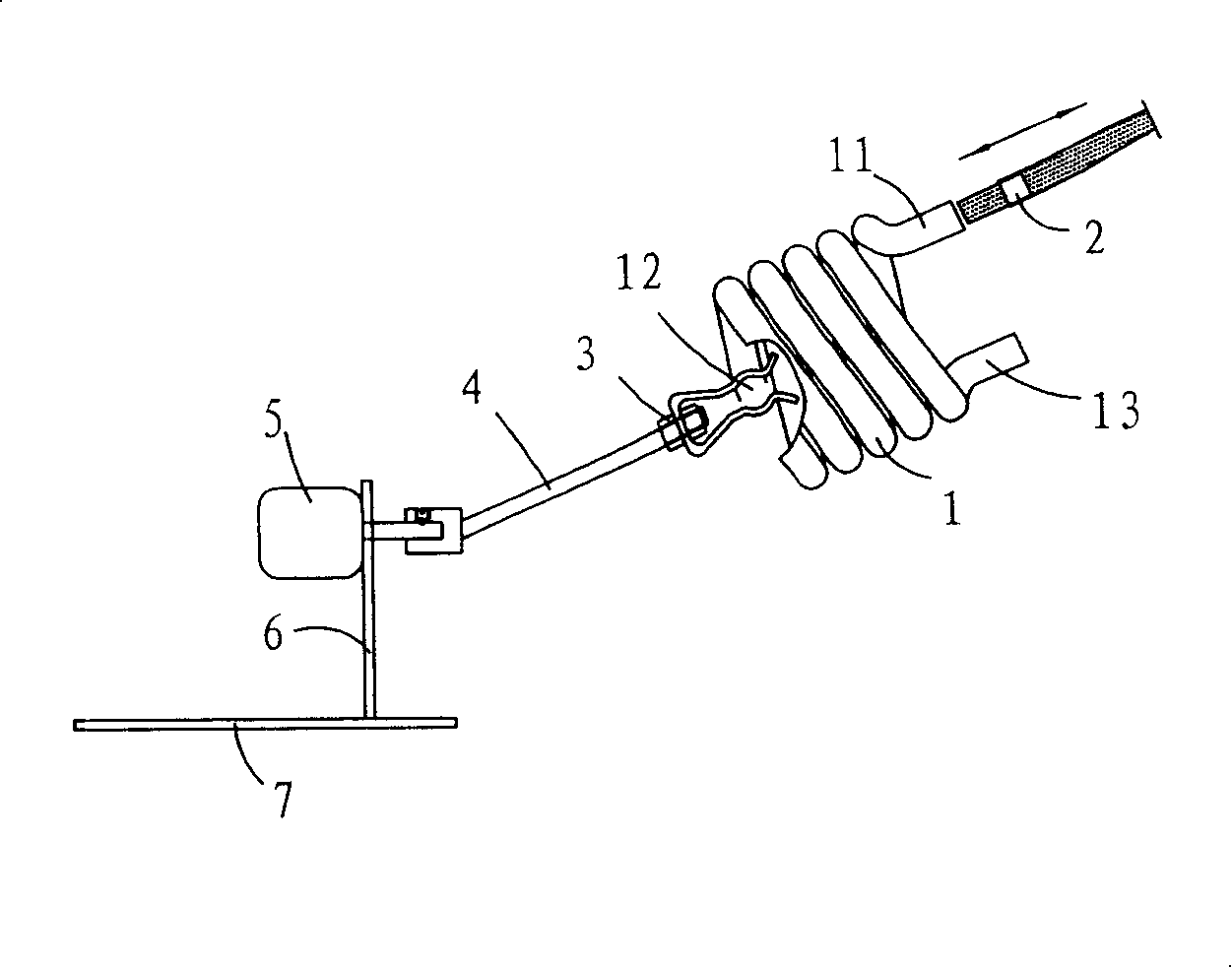

[0020] Such as Figure 3a , 3b , 3c, 3d, 3e, and 3f, a powder coating device for the inner wall of a full double-helix fluorescent lamp (patent applied for), including a spiral fluorescent lamp bright tube 1, a powder injection slurry conduit 2, and a spiral fluorescent lamp bright tube 1 A port 11 is aligned with the powder injection slurry conduit 2, and also includes an exposed pipe fixture 3, a rotary shaft 4, a motor 5, and a bracket 6; the exposed pipe fixture 3 clamps the spiral fluorescent lamp open pipe 1; one end of the rotary shaft 4 is installed with an exposed pipe fixture 3 , the other end is connected to the motor 5; the 4 axis of the rotary shaft coincides with the 1 axis of the spiral fluorescent lamp bright tube; the motor 5 is installed on the bracket 6, and multiple sets of the above-mentioned powder coating devices are installed on the rotary table 7 to become a powder coating machine that can rotate continuously . The electric motor 5 is a motor that ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com