Controllable weak magnetic technique combining magnetic structure with vector control of permanent magnet motor

A technology of vector control and permanent magnet motor, which is applied in the field of traction vehicles, can solve the problems of limited promotion and application, and achieve the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

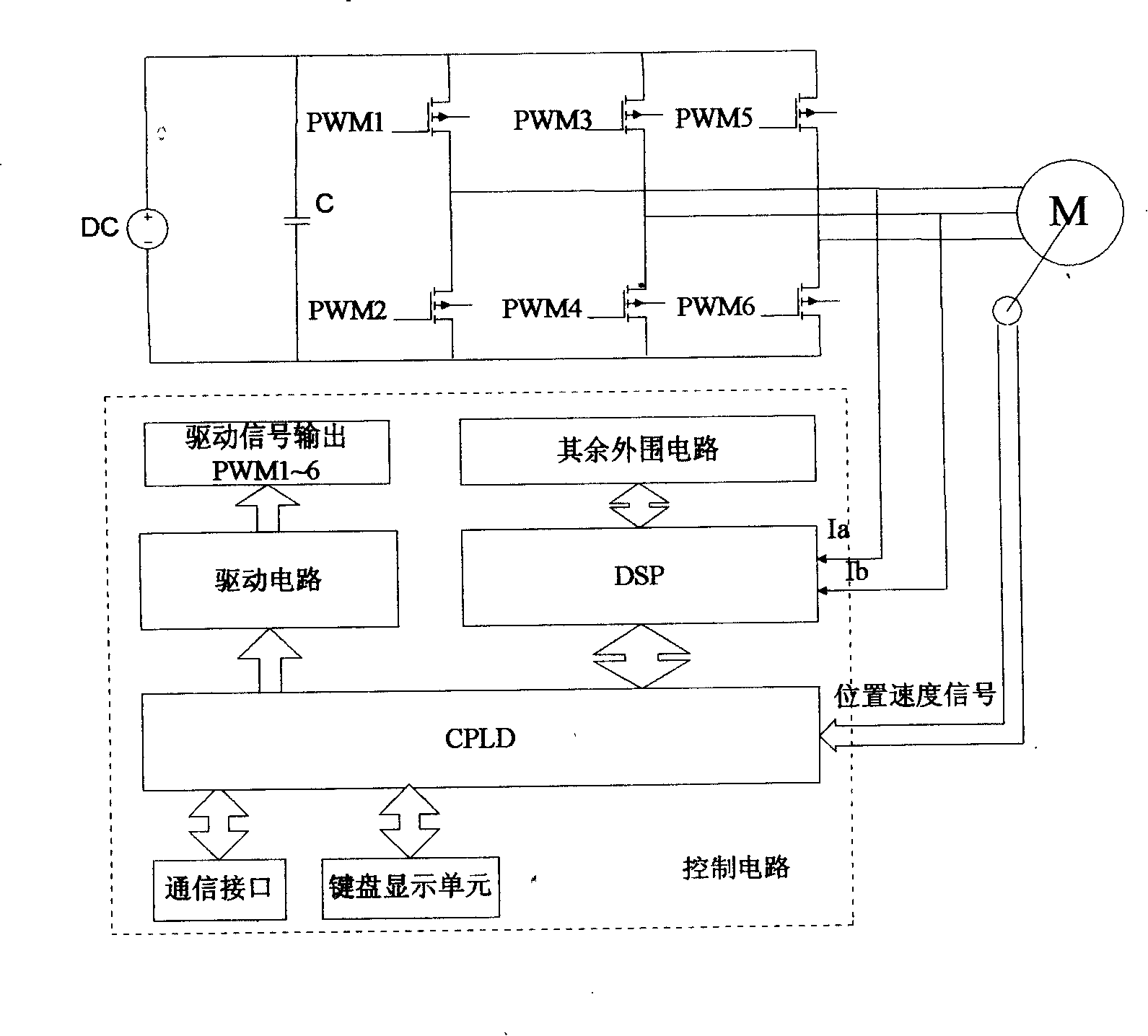

[0020] The rare-earth permanent-magnet synchronous motor control system that realizes wide-range field-weakening and speed expansion includes a multi-pole rare-earth permanent-magnet synchronous motor with a specially designed rotor magnetic circuit structure, a position and speed sensor, and a controller that implements space voltage vector control.

[0021] 1. Design of rotor structure of rare earth permanent magnet synchronous motor

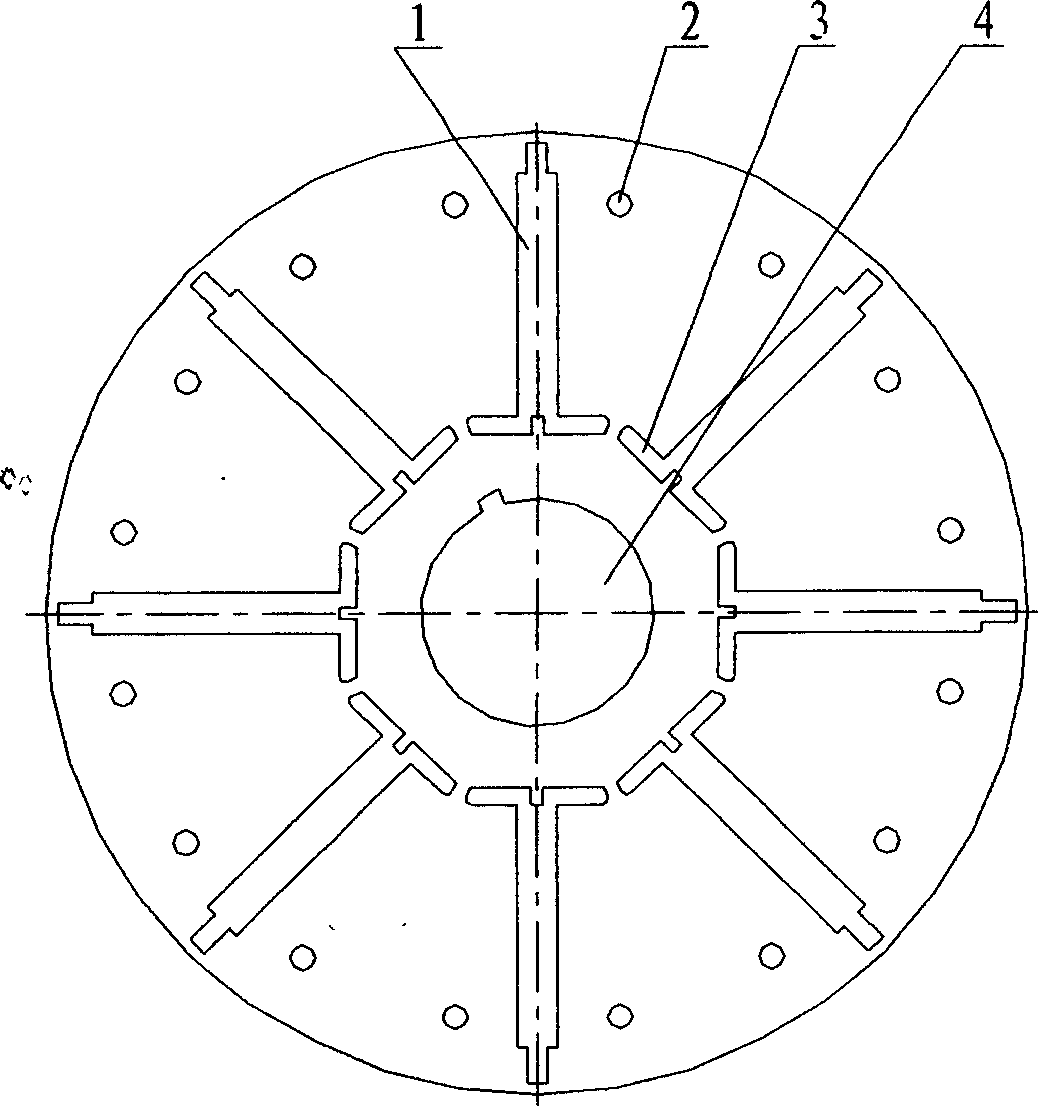

[0022] Rotor punching design such as figure 1 shown. In order to reduce the iron loss, the rotor is made of 0.5mm cold-rolled silicon steel sheet, in which sequence 1 is a 14mm×85mm rectangular permanent magnet installation slot, sequence 2 is a fastening hole for lamination, sequence 3 is a magnetic isolation groove, and sequence 4 is a shaft hole .

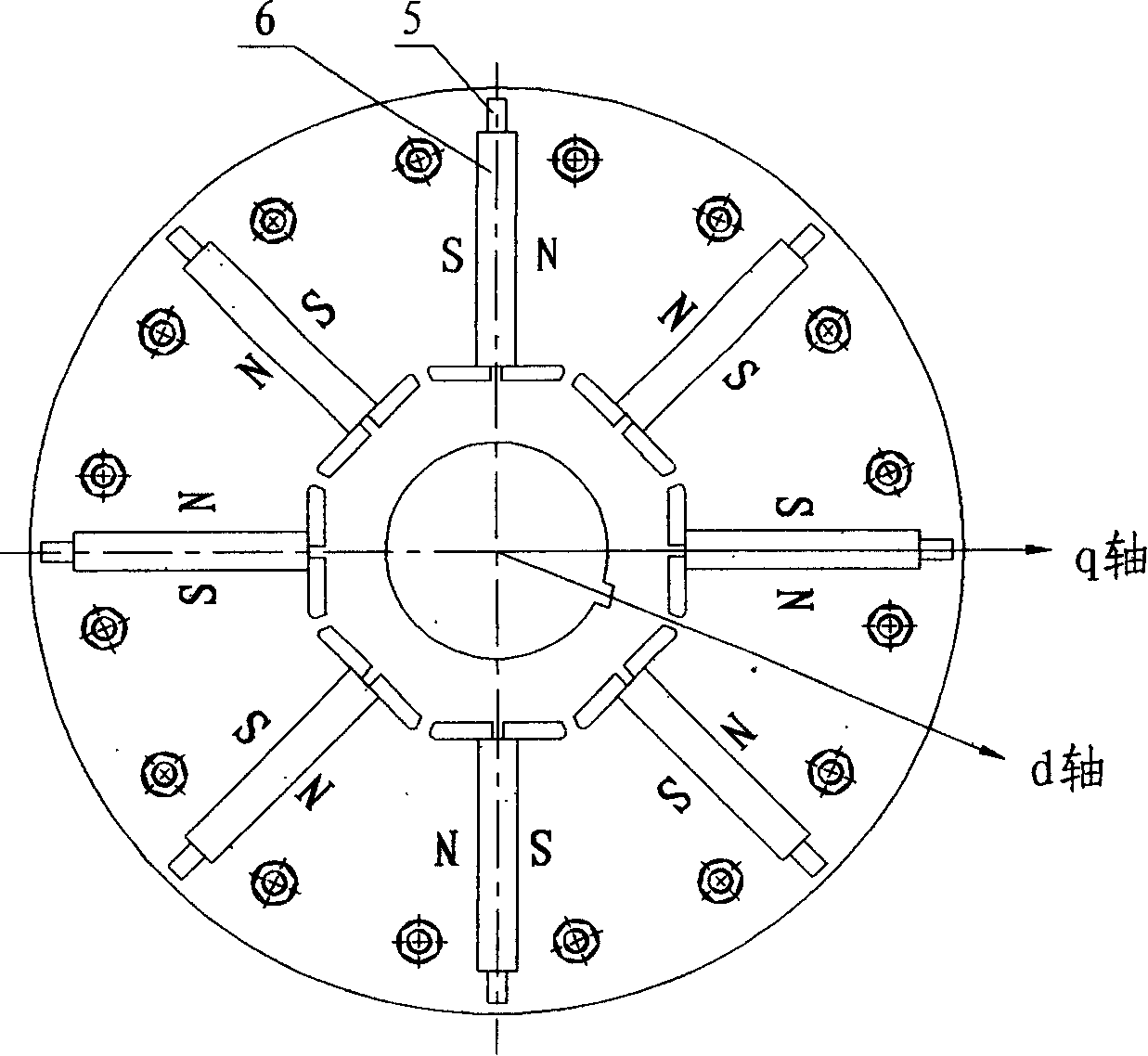

[0023] Rare earth permanent magnet synchronous motor rotor structure such as figure 2 shown. The rotor of the rare earth permanent magnet synchronous motor is formed by stacking several rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com