Process for increasing production of benzene from hydrocarbon mixture

A technology of hydrocarbon mixture and yield, which is applied in the direction of hydrocarbon oil treatment products, hydrocarbon oil cracking, refined hydrocarbon oil, etc., can solve the problem of not raising aromatic hydrocarbons, and achieve the effect of increasing yield

Inactive Publication Date: 2008-06-25

SK ENERGY CO LTD (KR)

View PDF3 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, no method has been proposed to combine competing methods to increase the yield of aromatics, especially benzene

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1 and comparative example 1、2

[0056] It is necessary to determine the yield of the separate process and the combined process of the present invention, therefore, tests were performed in the following examples.

Embodiment 1

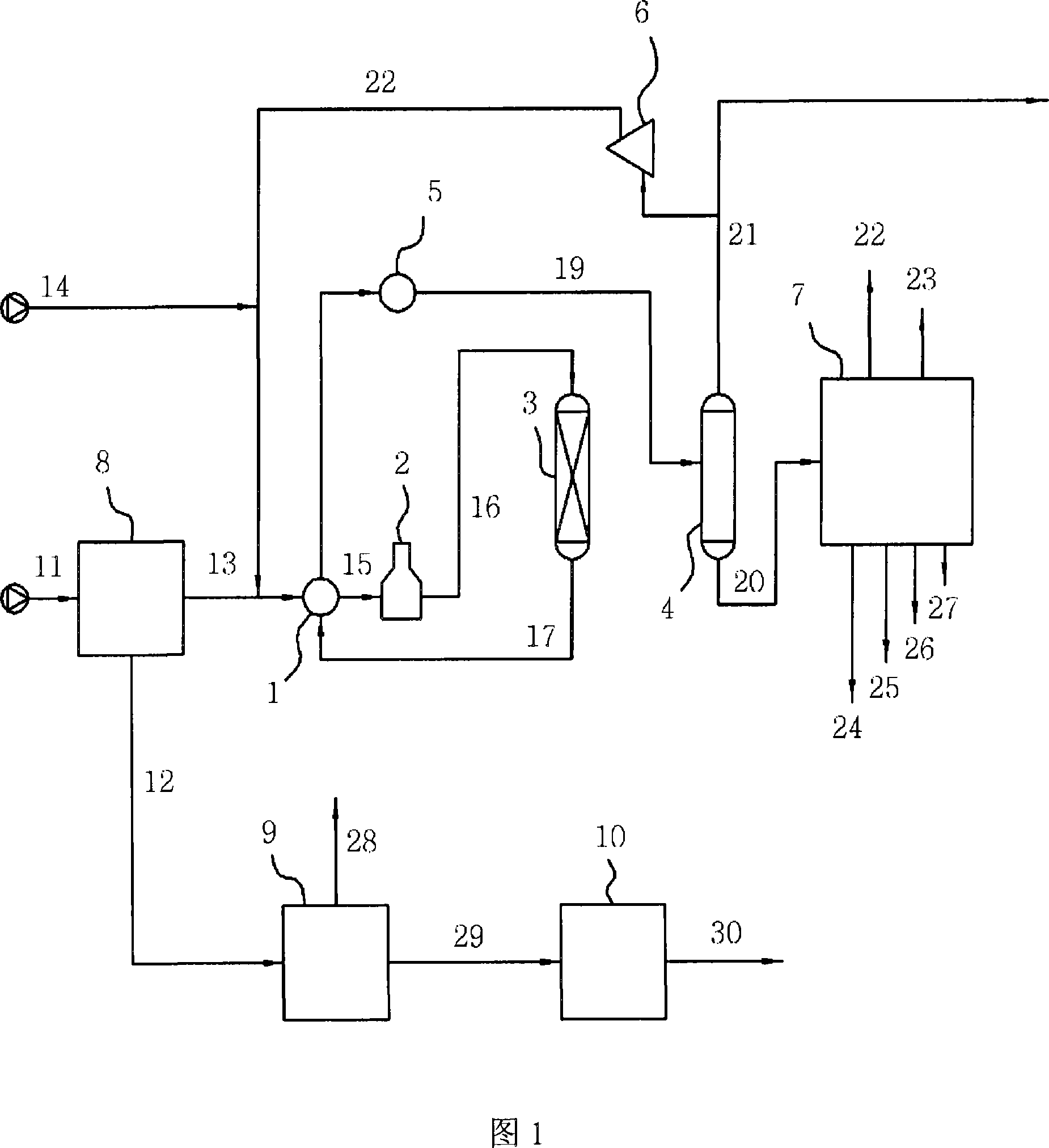

[0069] The yield of the combined process using pyrolysis gasoline as a raw material as shown in Figure 1 was tested, and the results are shown in Table 3.

[0070] table 3

[0071] Solvent extraction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Login to View More

Abstract

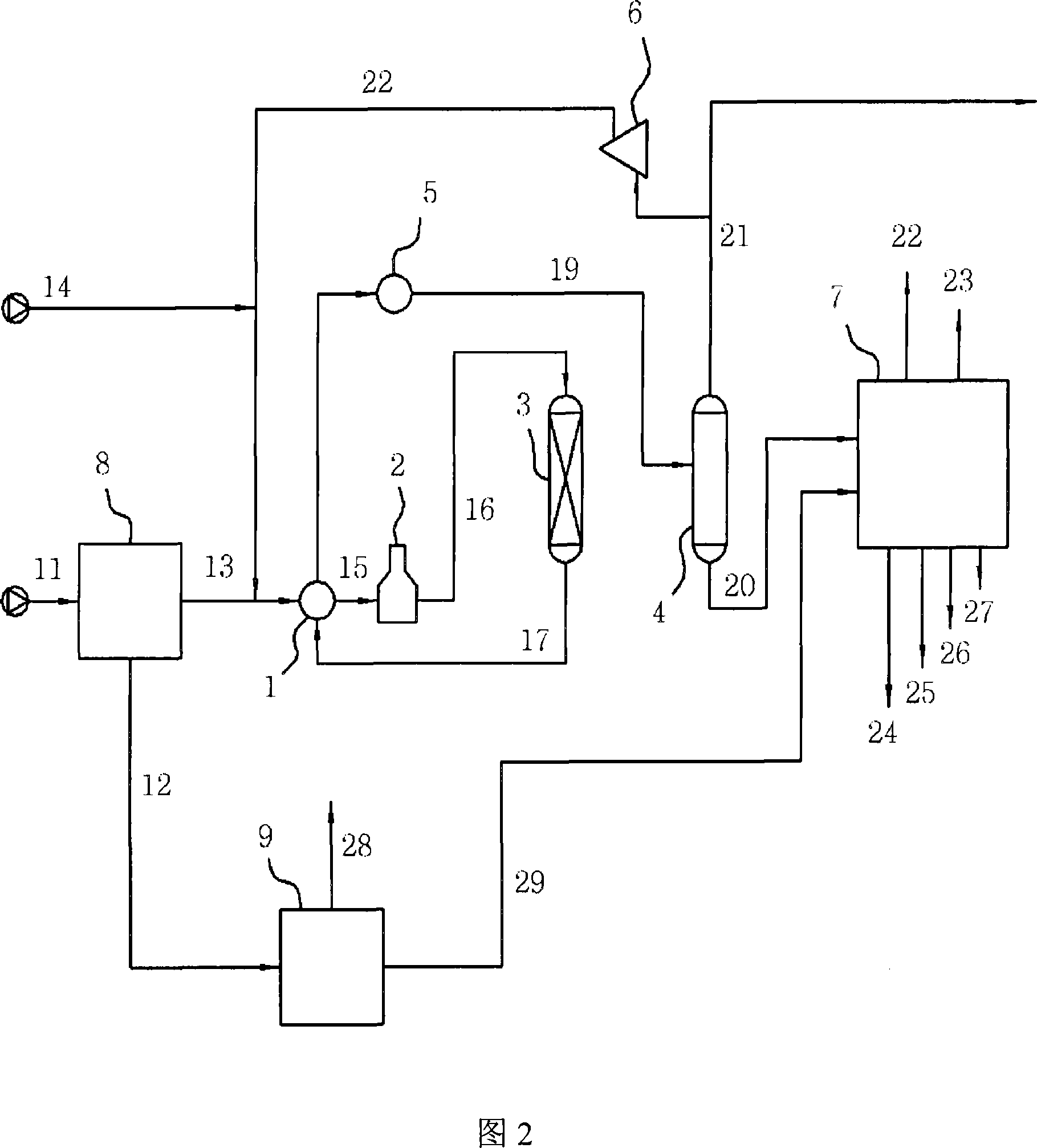

Disclosed herein is a process for increasing the production of benzene from a hydrocarbon mixture. A process for producing an aromatic hydrocarbon mixture and LPG from a hydrocarbon mixture, and a solvent extraction process for separating and recovering polar hydrocarbons from a hydrocarbon mixture containing polar hydrocarbons (that is, aromatic hydrocarbons) and nonpolar hydrocarbons (that is, non-aromatic hydrocarbons) are integrated, thereby it is possible to increase the production of benzene.

Description

Technical field [0001] The present invention relates to a method for increasing the yield of benzene prepared from a hydrocarbon mixture. More specifically, the present invention relates to a method for improving the yield of benzene by combining the process of preparing an aromatic hydrocarbon mixture and liquefied petroleum gas (LPG) from a hydrocarbon mixture with a solvent extraction process for separating and recovering polar hydrocarbons from the hydrocarbon mixture. Methods. Background technique [0002] Generally, aromatic hydrocarbons are separated from non-aromatic hydrocarbons by solvent extraction method to separate raw material fractions rich in aromatic compounds (such as reformed oil made by catalytic reforming process and pyrolysis gasoline made by naphtha cracking process). obtain. The aromatic hydrocarbon mixture thus obtained is separated into benzene, toluene, xylene, and C9+ aromatic compounds according to different boiling points to be used as basic petroche...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10G7/08

CPCC10G45/58C10G2400/30C10G61/08C10G45/64C10G45/68C10G67/16C10G21/00C10G47/18C10G21/27C10G2400/28C10G47/00C10G35/095C07C7/10C10G7/08

Inventor 崔先吴承勋成京学李宗炯姜信喆金容昇林炳秀张炳武

Owner SK ENERGY CO LTD (KR)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com