Building solid castoff specification regeneration system and method

A solid waste and recycling system technology, applied in the field of waste treatment, can solve the problems of dust pollution, large floor space, low added value of recycled aggregates, etc., and achieve the effects of low noise, compact equipment layout, and resource realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

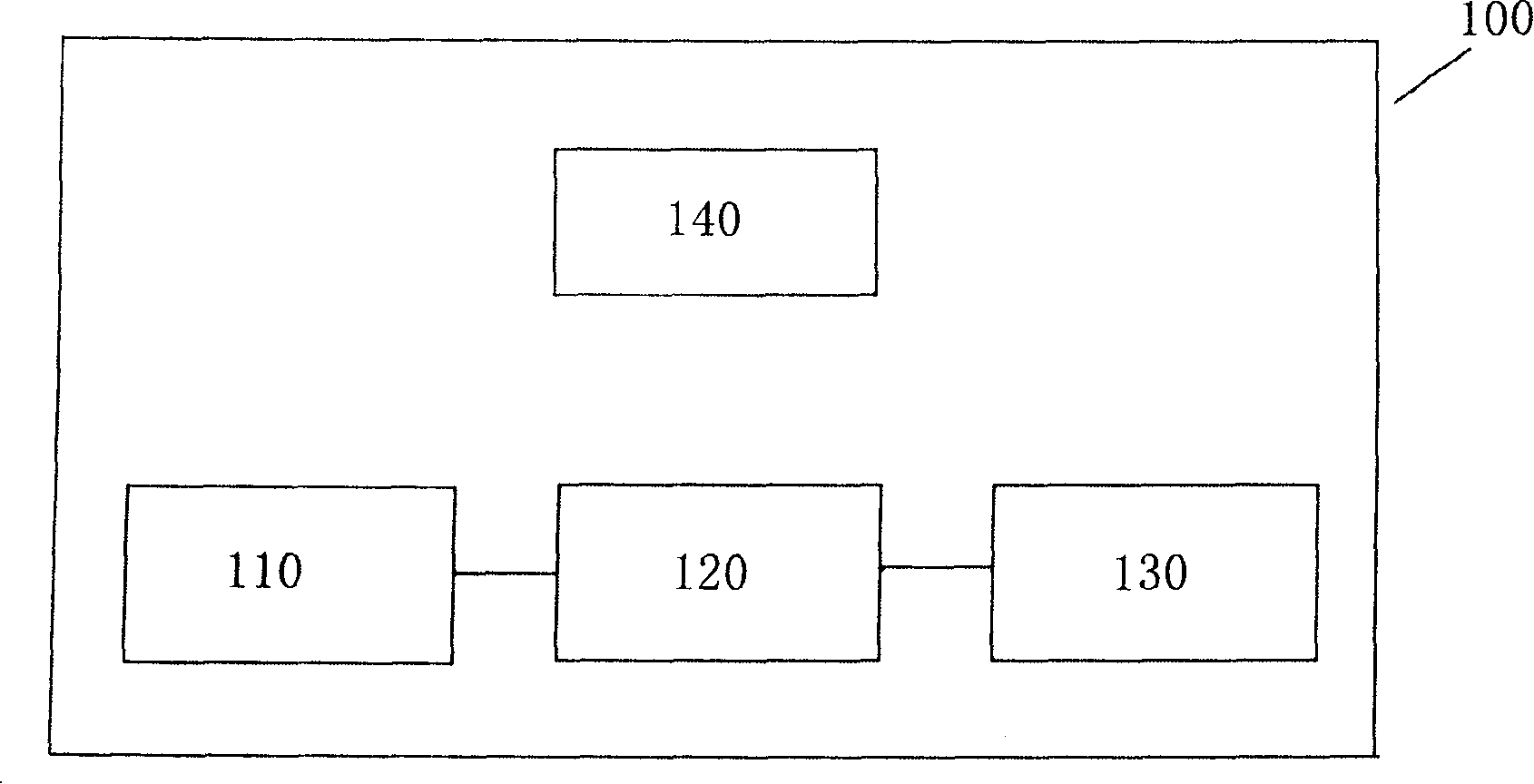

[0029] Such as figure 1 As shown, the construction solid waste sorting and recycling system of the present invention includes a steel structure 100 with an accommodating space inside, and a feeding unit 110 is arranged in the steel structure, and a feeding unit 110 is connected A crushing unit 120 , a screening unit 130 connected to the crushing unit, and a dust removal unit 140 is further arranged in the steel structure 100 .

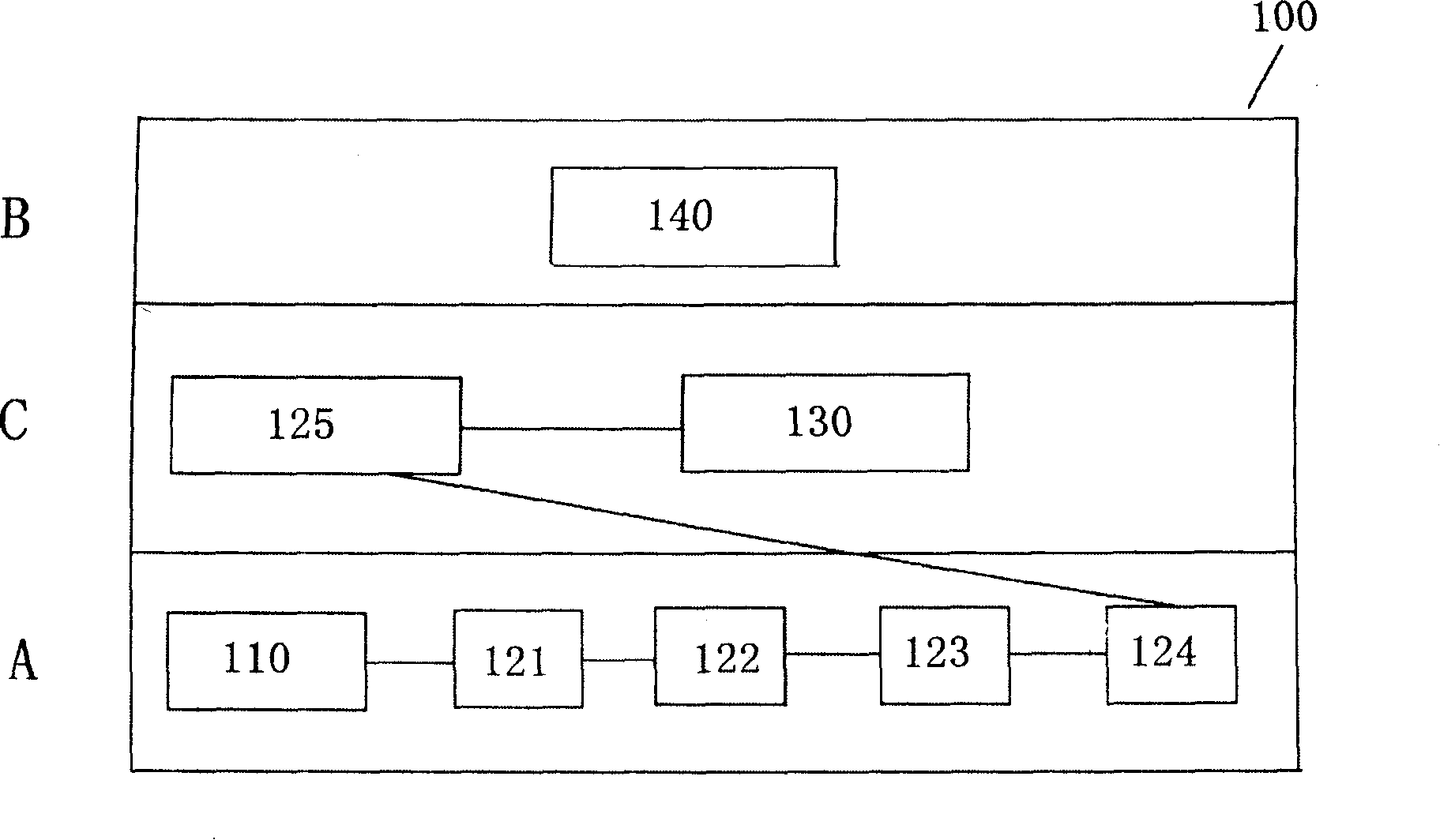

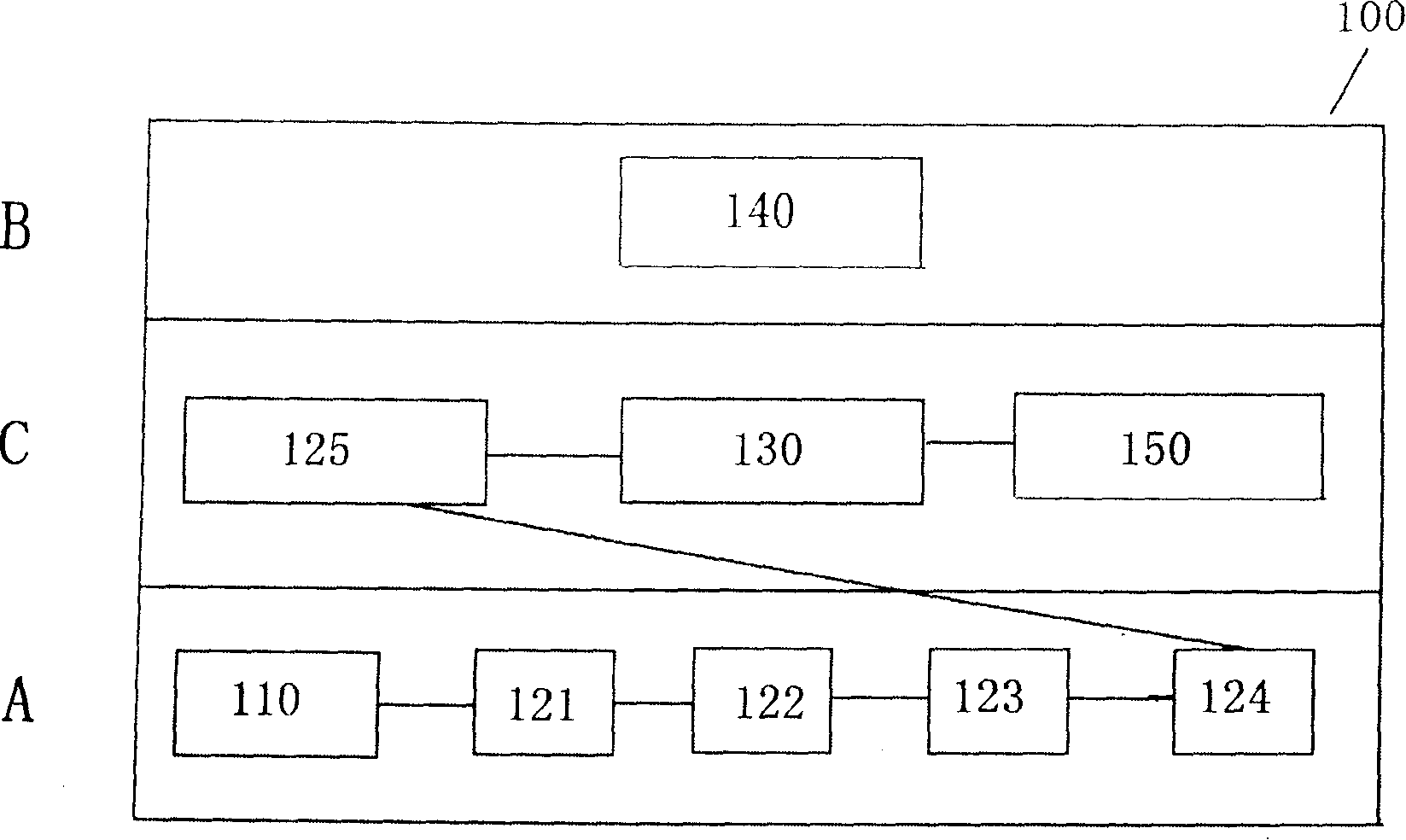

[0030] Specifically, further reference figure 2 As shown, the steel structure 100 at least includes a bottom layer A, a top layer B and at least one middle layer C between the bottom layer A and the top layer B.

[0031] The feeding unit 110 is a commonly used feeder in the construction field, such as a vibrating feeder. The crushing unit 120 includes a rough breaking device 121, a classifying device 122, a washing device 123, a medium breaking device 124 and a fine breaking device 125 which can be connected in sequence by a conveyor belt; the rough...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com