Glass chute and its assembling structure

A glass run, assembly structure technology, applied in sealing devices, transportation and packaging, engine sealing, etc., can solve problems such as loss of meaning and decreased manufacturing efficiency, and achieve the effect of reducing manufacturing steps and manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

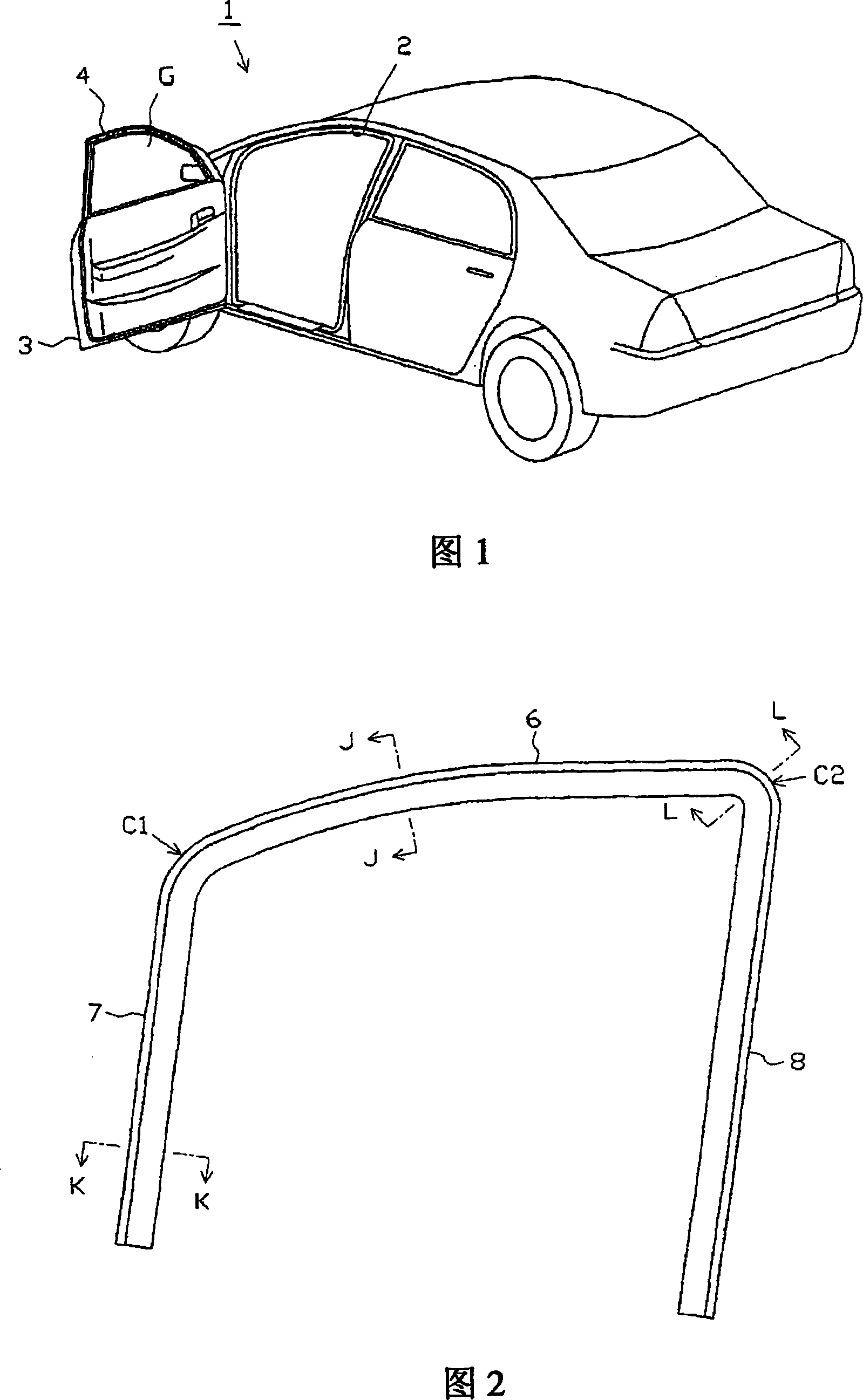

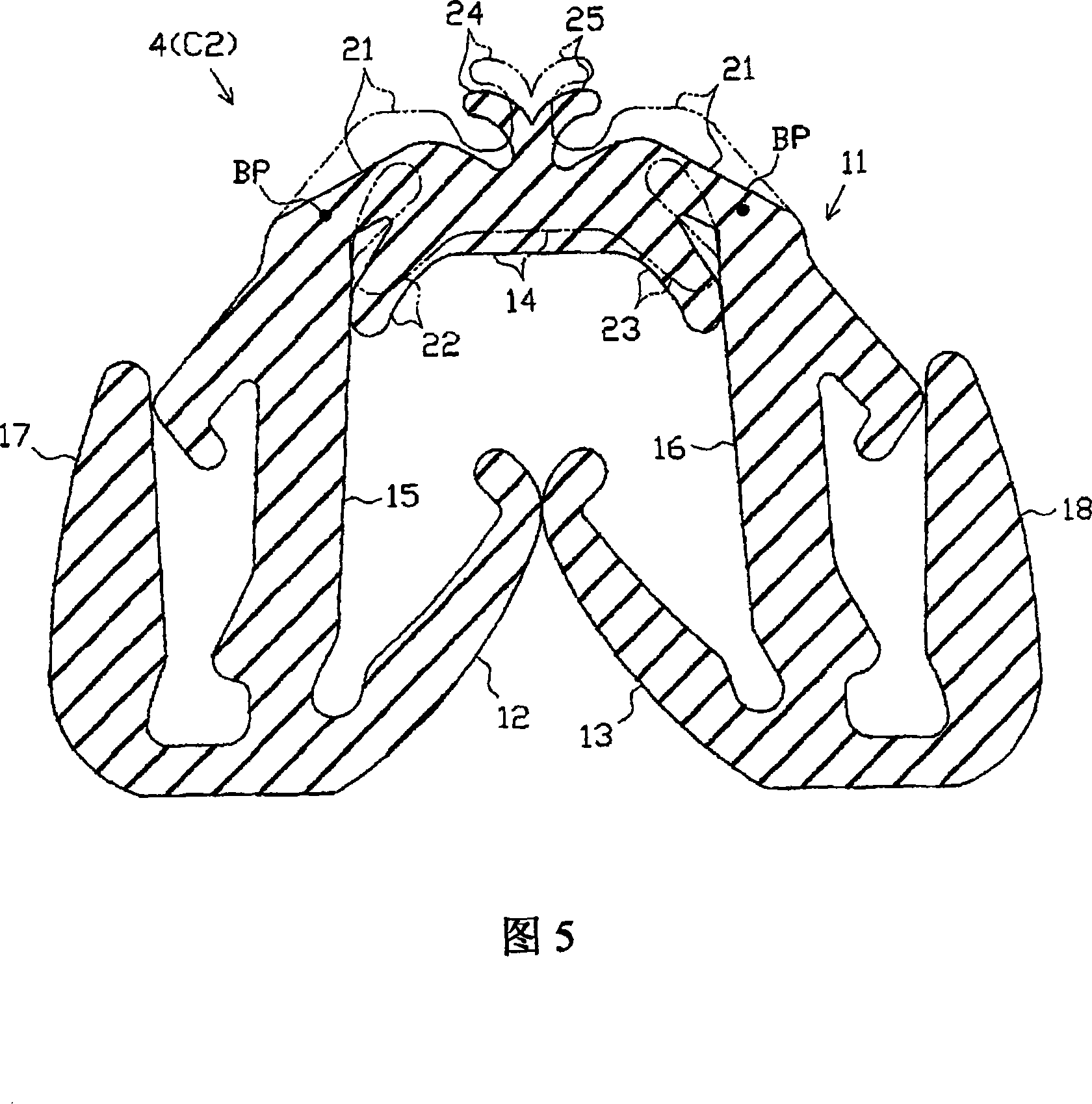

[0072] The first embodiment will be described below with reference to the drawings. As shown in FIG. 1 , a door opening 2 of a motor vehicle 1 (as a vehicle) is provided with openable and closable front doors 3 (hereinafter, simply referred to as doors). The door 3 includes: a door glass G that can be lifted and lowered and a glass run 4 corresponding to the shape of the outer periphery of the door glass G.

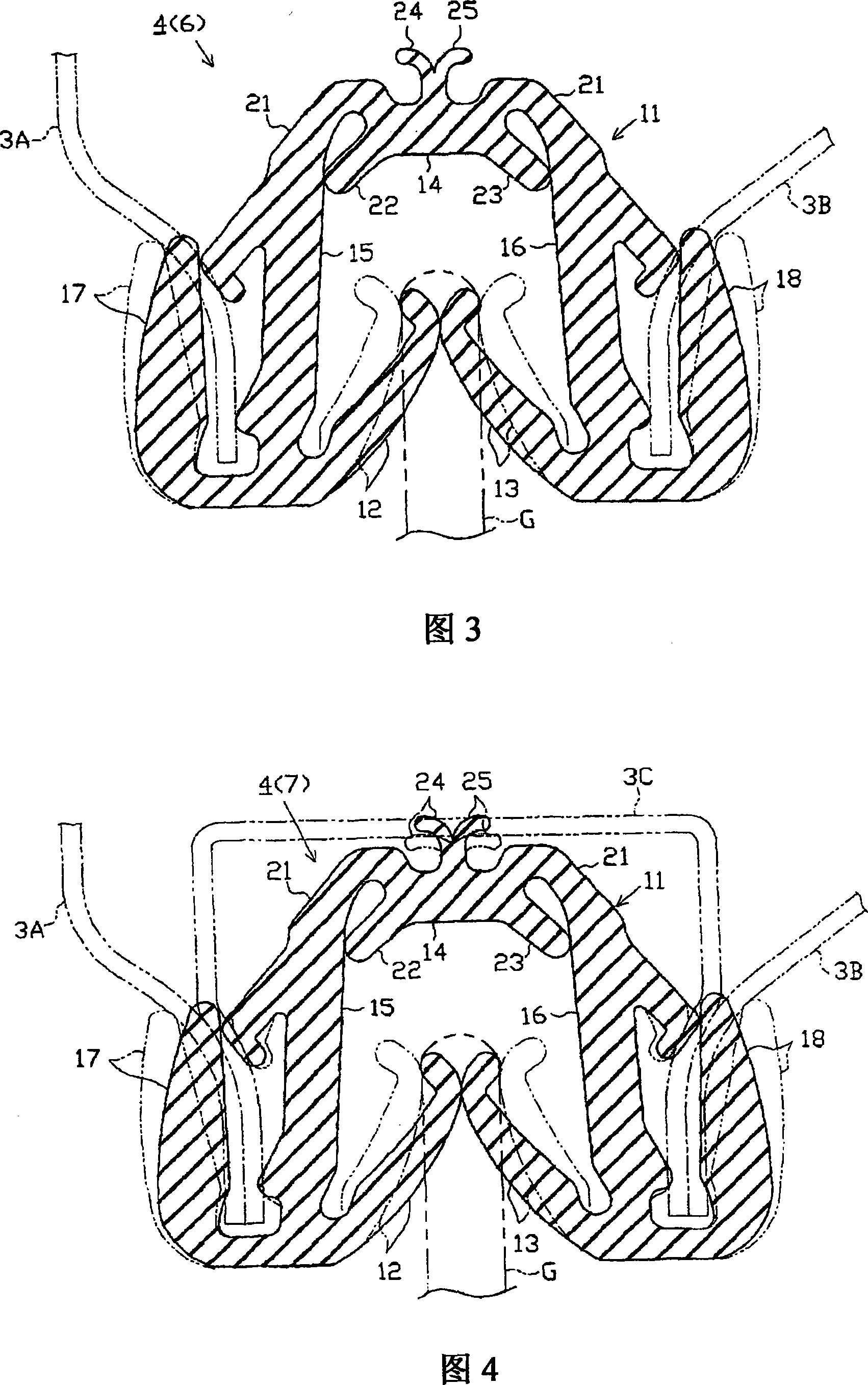

[0073] As shown in FIG. 2 , the glass run channel 4 includes: an upper side portion 6 constituting a portion corresponding to the upper edge portion of the door glass G; a front vertical side portion 7 constituting a front end portion from the upper side portion 6 (corresponding to the and the rear vertical side portion 8 constituting a portion extending downward from the rear end portion of the upper side portion 6 (corresponding to the rear edge portion of the door glass G). The glass run channel 4 of the present embodiment is made of EPDM (ethylene-propylene-diene cop...

no. 2 example

[0088] A second embodiment will be described below with reference to the drawings. Fig. 6 is a schematic front view of the general structure of the door. Fig. 7 is a sectional view along line X-X in Fig. 6, showing the upper side of the glass run. Fig. 8 is a cross-sectional view along line Y-Y showing the glass run channel at the corner. Figure 9 is a sectional view along line Z-Z showing the rear vertical side of the glass run.

[0089] As shown in FIG. 6, a front door 101 (hereinafter referred to simply as a door) is configured to be openable / closeable in a door opening for a motor vehicle door, and is provided with a door glass G and a glass run 105, and the glass run 105 is set as The glass run groove 105 seals the gap between the outer periphery of the door glass G and the door frame 102 when the door glass G is raised and closed to close the glass opening part W corresponding to the outer peripheral shape of the door glass G. . Furthermore, the door 101 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com