Technique for processing and recovering disuse acidic copper etchant by metal aluminum

A technology of copper etching and metal aluminum, which is applied in metallurgical wastewater treatment, reduced water/sewage treatment, etc., can solve the negative effects of reaction speed and reaction degree, etc., and achieve the effect of easy removal, easy on-site treatment, and efficient reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0029] This example uses 200 ml of 25% spent etchant, added in small pieces of aluminum diamond foil with a surface area of 28.3 cm2 per gram.

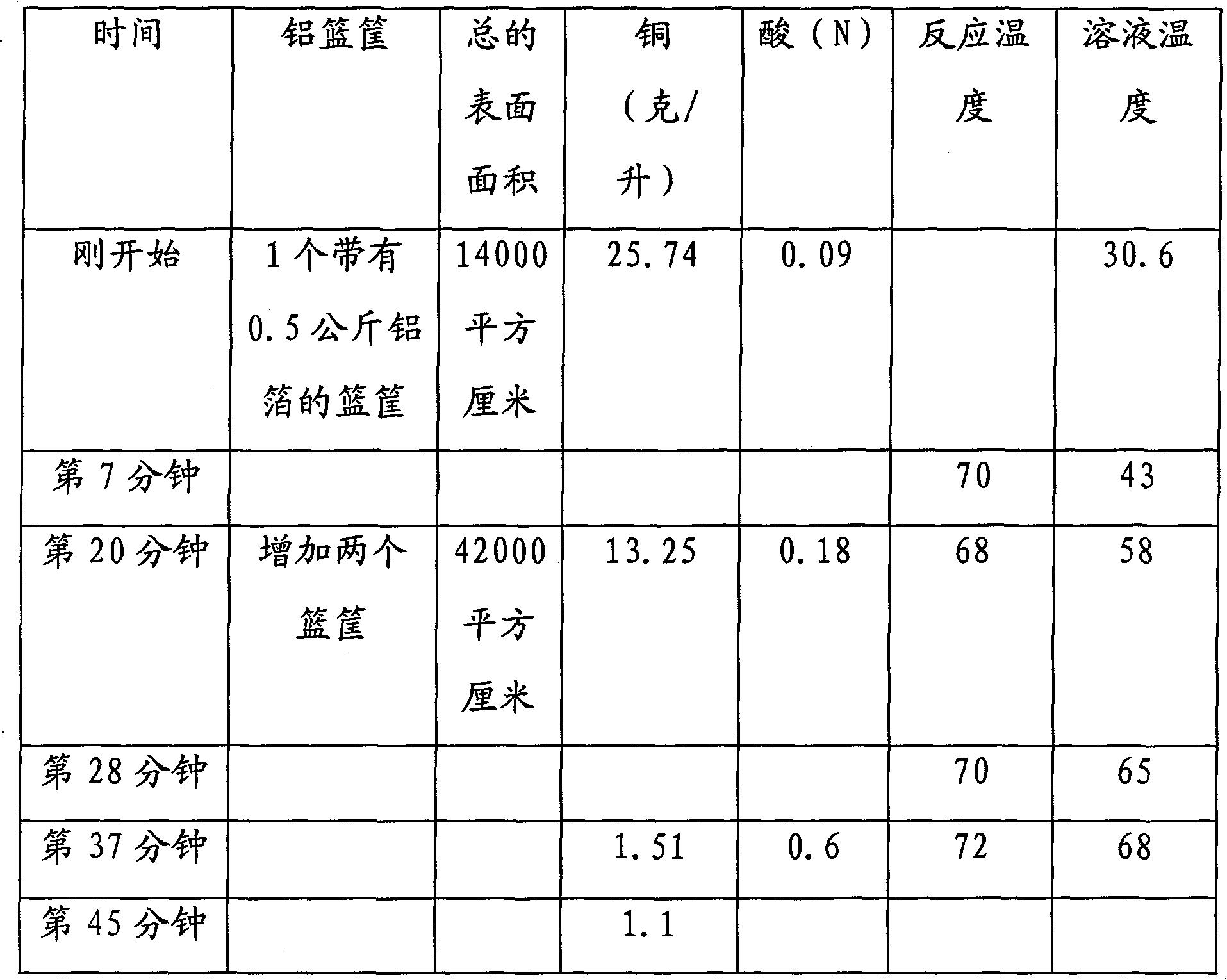

[0030] Table of Example 1

[0031]

example 2

[0033] This example uses 200 ml of 50% spent etchant, added in small pieces of aluminum diamond foil with a surface area of 28.3 cm2 per gram.

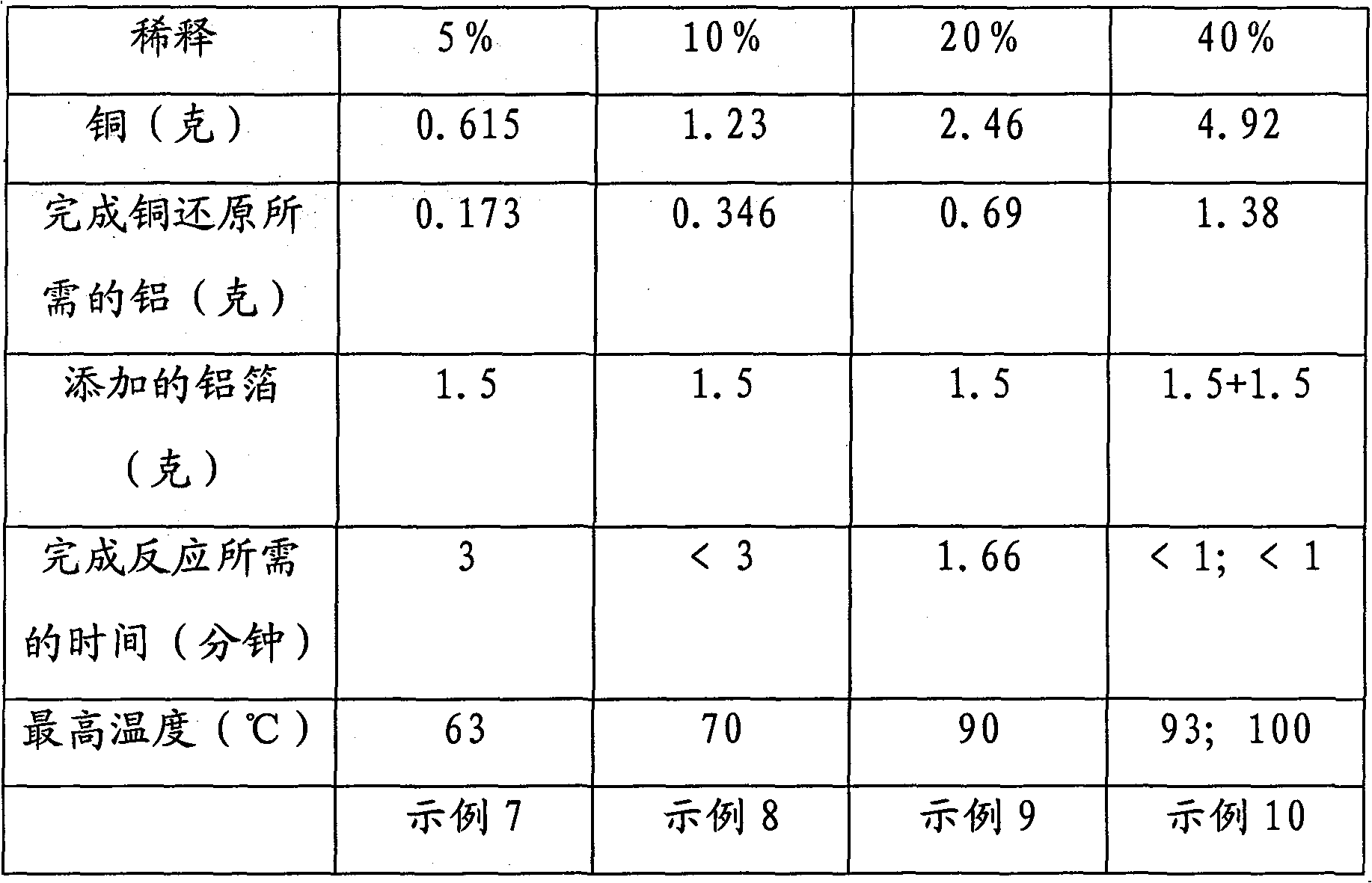

[0034] Table of Example 2

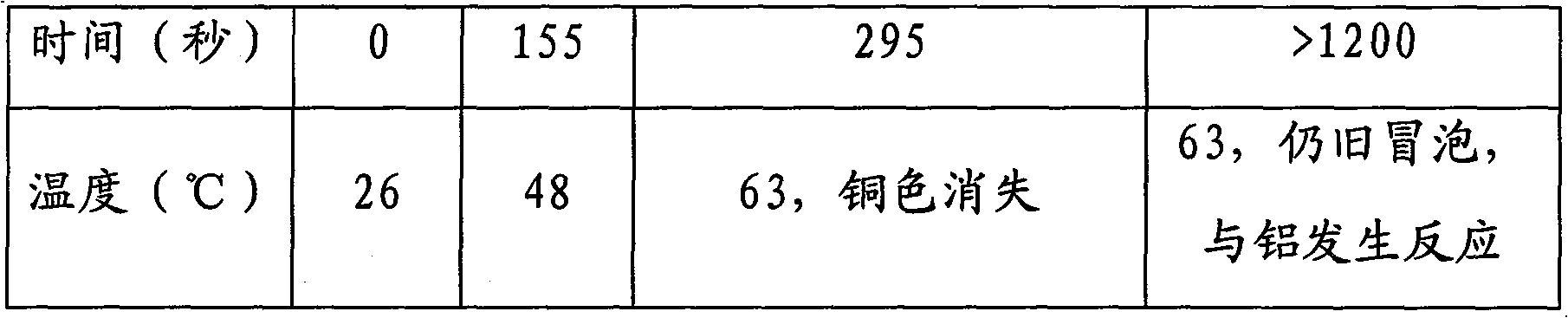

[0035] time (seconds)

[0036] Obviously, the reaction of 50% solution is too violent, while the maximum temperature of 25% is only 63°C. Once the solution reached around 80°C, a runaway reaction occurred and, in other tests using slightly higher concentrations of copper, caused the solution to boil over. 70°C is an environmentally friendly upper temperature limit, which appears to be manageable. Below 40°C, the reaction is too slow for optimal industrial use.

example 3

[0038] 100% spent etchant was used, but the reaction was so violent that even a small amount of aluminum was added, and some solutions would boil over.

[0039] After the copper has been reduced, the aluminum continues to react with the free acid. This reaction is very slow compared to the copper reduction reaction. The final product will use the aluminum to completely neutralize the acid, as the pH increases significantly, the aluminum chloride hydrolyzes and the aluminum hydroxide precipitates. For the field of waste treatment, an acidic solution of aluminum chloride would be an ideal product. It will be used to treat industrial wastewater, pre-purify drinking water and precipitate solids from treated domestic sewage. The acidic aluminum chloride solution can also be used as an industrial raw material, for example for the production of polyaluminum chloride, other waste treatment compounds. This acidic solution can also be simply neutralized and sold as aluminum hydroxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com