Method for recycling disuse concrete and device thereby

A waste concrete and concrete technology, applied in solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problems of high recycling cost, mechanical wear and maintenance costs, and low sand and gravel, and achieve low-cost and thorough recycling , less maintenance costs, the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

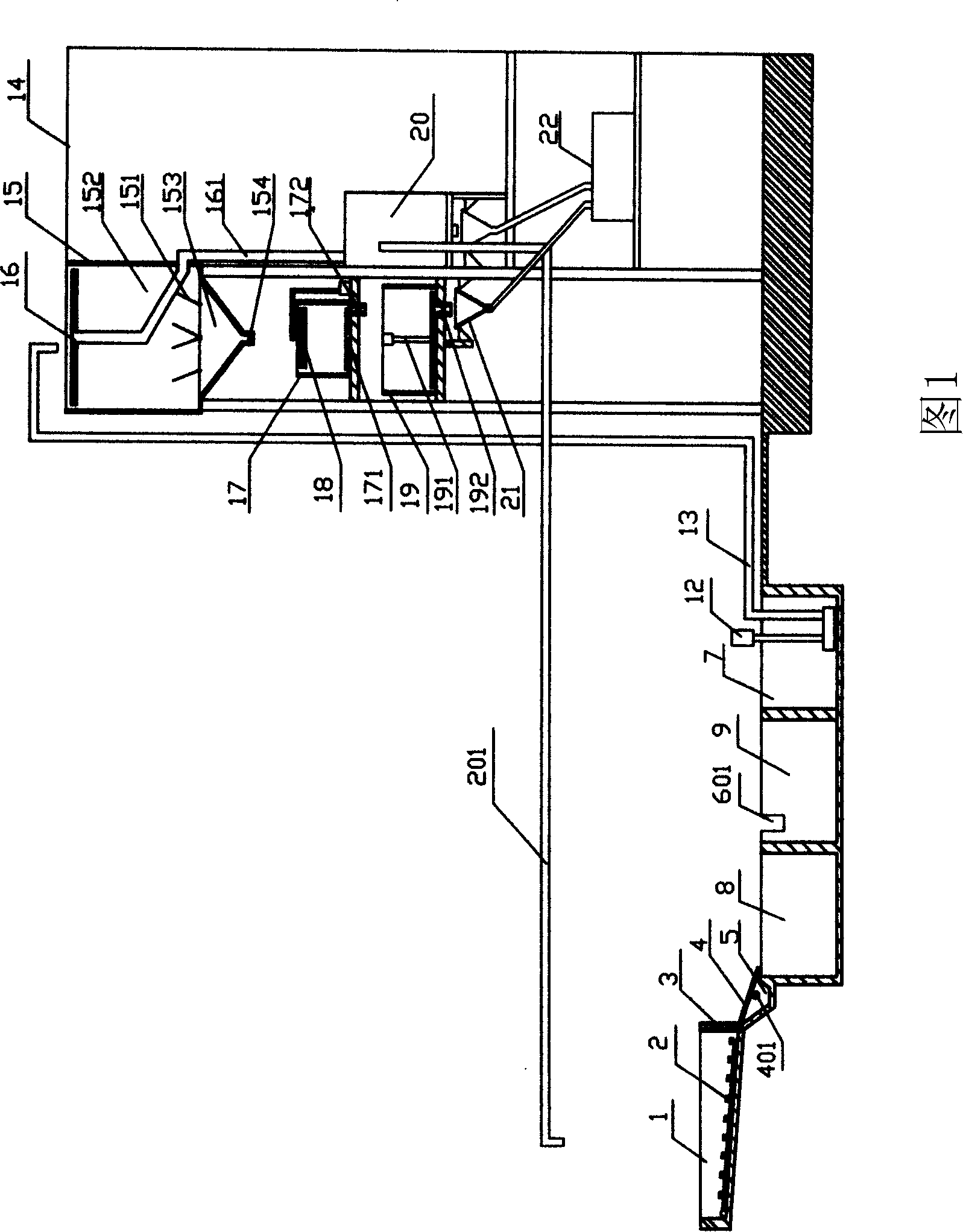

Embodiment approach 1

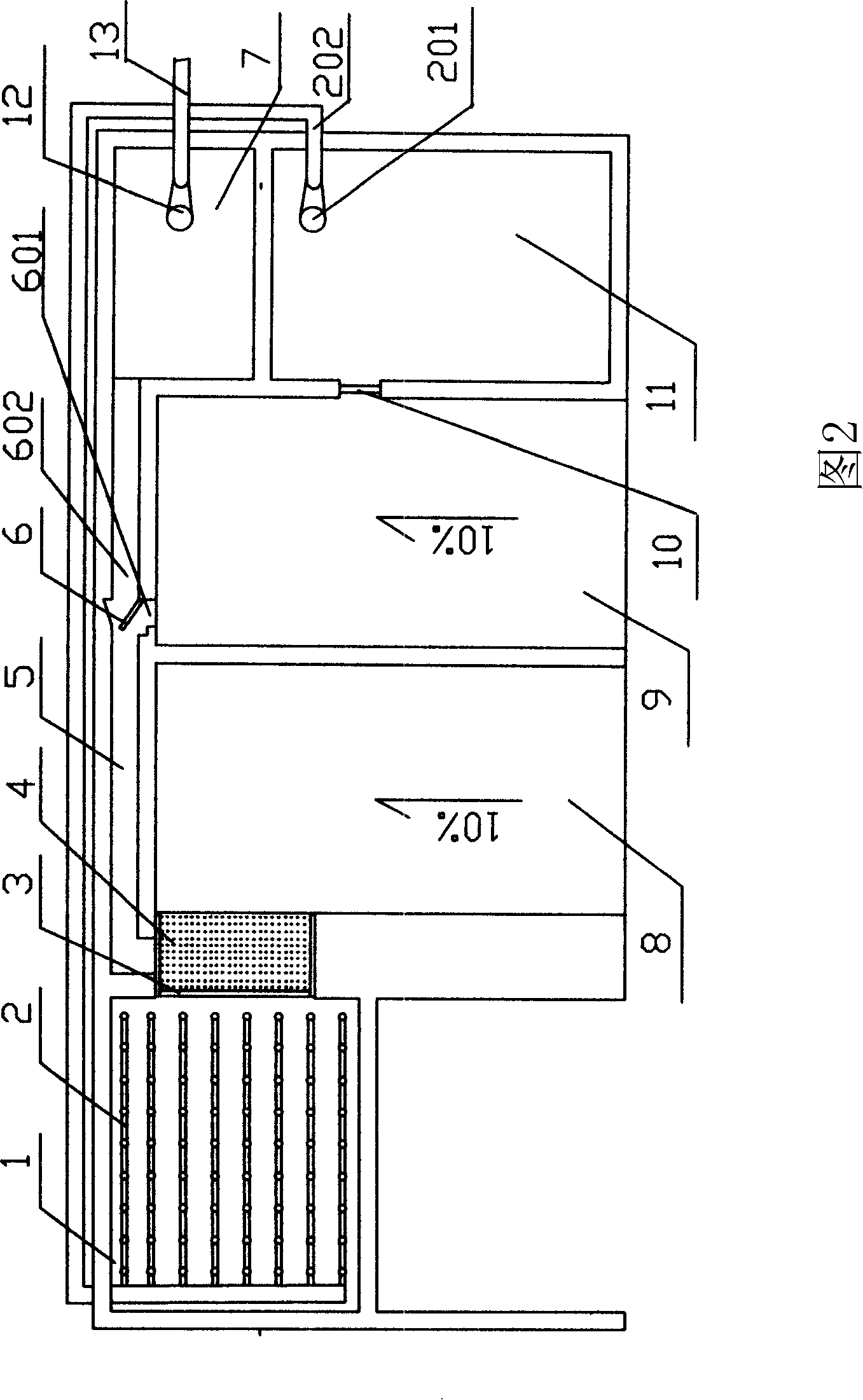

[0040] 1. Close the filter screen 3, close the gate 6 in the ditch 5 to the gate 601 of the sand bin, and make the gate 602 of the slurry pool 7 open.

[0041] 2. After the mixer truck completes the transportation task and returns to the station to add water to clean the drum, the discarded concrete and slurry water in the drum are discharged into the storage tank 1, and the slurry water flows into the slurry through the slurry water filter 3, the vibrating screen 4 and the water ditch 5 Pond 7; Gravel lives in feed storage tank 1 by filter screen 3 bars.

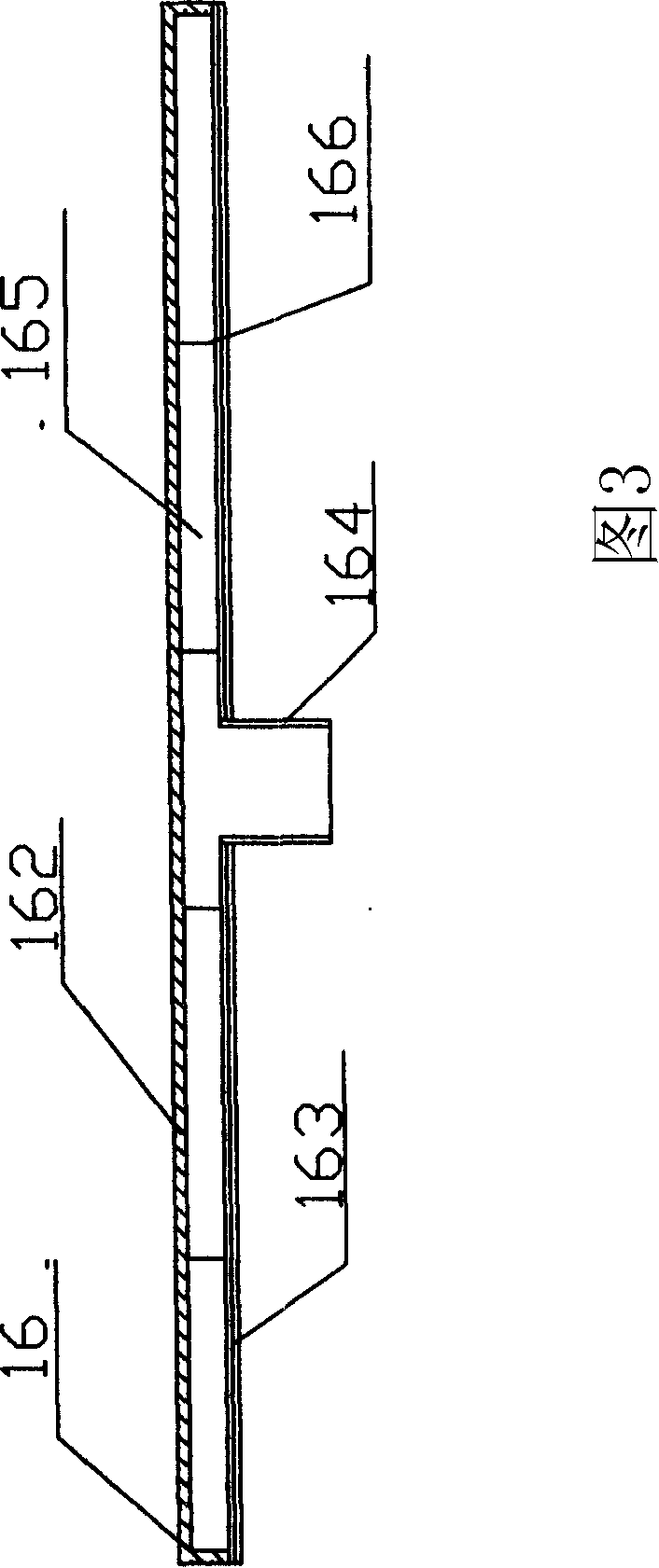

[0042] 3. Turn on the mud pump 12 in the slurry tank 7, pump all the slurry water into the sedimentation tank 15 above the side of the mixing building 14 through the slurry water pipeline 13, and the water flows into the storage tank through the filter 16 suspended on the slurry water surface and the clean water pipe 161 In the water tank 20; The gelled material settles to the gelled material accumulation area 153 at the bo...

Embodiment approach 2

[0052] 1. Close the filter screen 3, close the gate 6 in the ditch 5 to the gate 602 leading to the sand bin 9, and make the gate 601 leading to the slurry pool 7 open.

[0053] 2. Use a loading truck to pour the waste concrete that has not yet finalized into the storage tank 1, turn on the flushing system 2, and the slurry water flows into the slurry pool 7 through the filter screen 3, the vibrating screen 4 and the ditch 5; the sand and gravel are filtered The net 3 columns live in the storage tank 1.

[0054] 3. Turn on the slurry pump 12 in the slurry tank 7, pump all the slurry water into the sedimentation tank 15 above the side of the mixing building 20 through the slurry water pipeline 13, and the water flows into the storage tank through the filter 16 suspended on the slurry water surface and the clean water pipe 161 In the water tank 20 , the gelled material settles to the gelled material accumulation area 153 at the bottom of the settling tank 15 .

[0055] 4. Close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com