Refraction-diffraction mixed telescope optical system

An optical system and a refracting-diffractive hybrid technology, which is applied in the field of refracting-diffractive hybrid telescope optical systems, can solve the problems of processing and inspection difficulties of sub-reflectors, and achieve the effects of reducing assembly difficulty, manufacturing cost, and manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

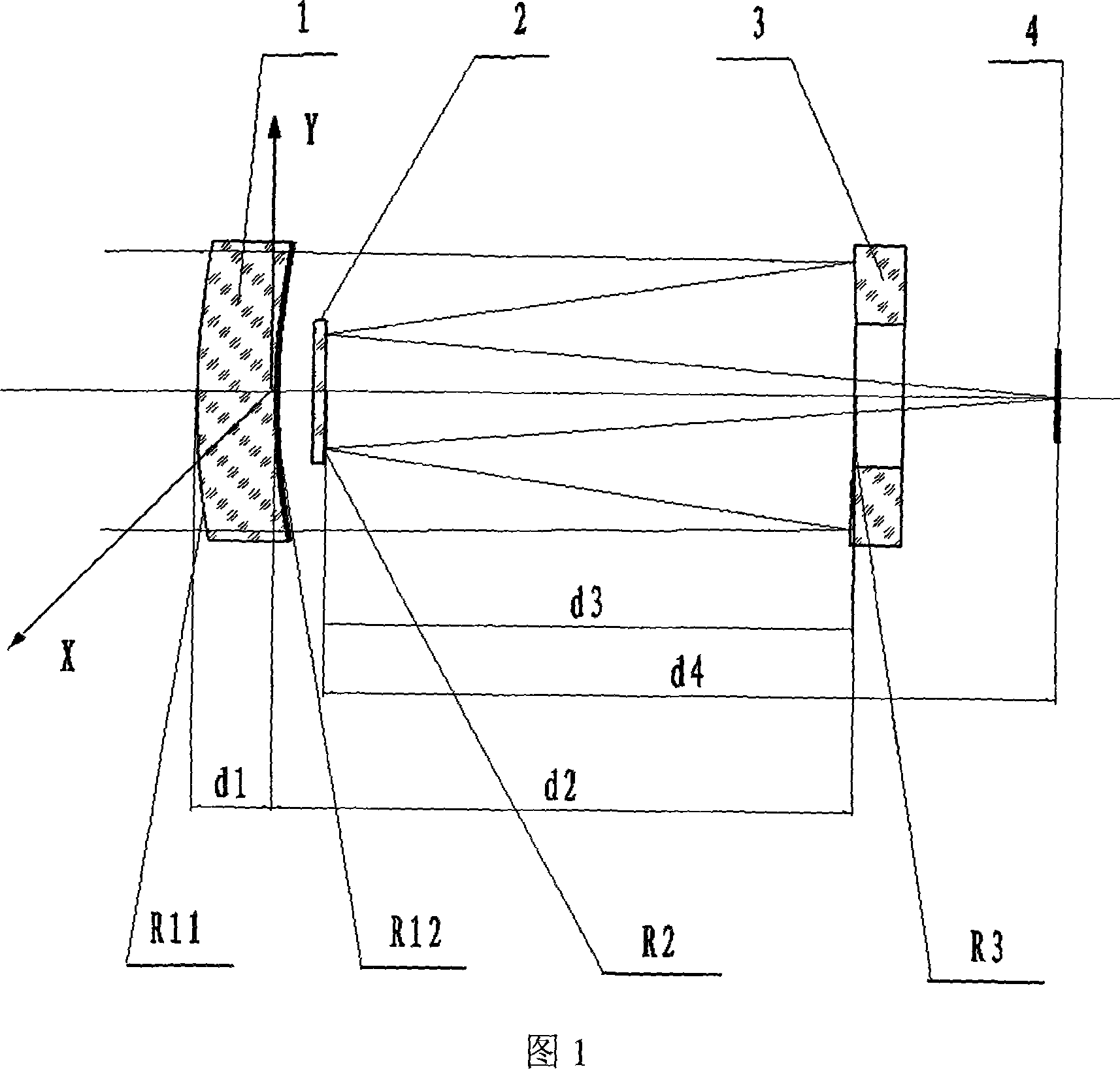

[0025] According to the optical structure of attached drawing 1, we designed the optical system of a fold-diffraction hybrid telescope. The correction mirror 1 is made of quartz glass material. The field of view of the optical system is equivalent to that of the Ridge-Krekion telescope, and the optical design result is close to the imaging quality of the system Diffraction limit. The specific technical indicators of the optical system are as follows:

[0026] Telescope aperture: φ125mm;

[0027] Relative aperture D / F: 1 / 8;

[0028] System focal length: 1000mm;

[0029] Working wavelength: 0.4861μm~0.6563μm;

[0030] Full field of view: 20';

[0031] The specific structural design parameters of the optical system are shown in Table 1.

[0032] Table 1

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com